Conversion type adsorption and desorption device and method thereof

An adsorption-desorption, conversion-type technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, special treatment targets, etc., can solve problems such as unbalanced adsorption and desorption, and achieve improved cycle utilization and adsorption efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

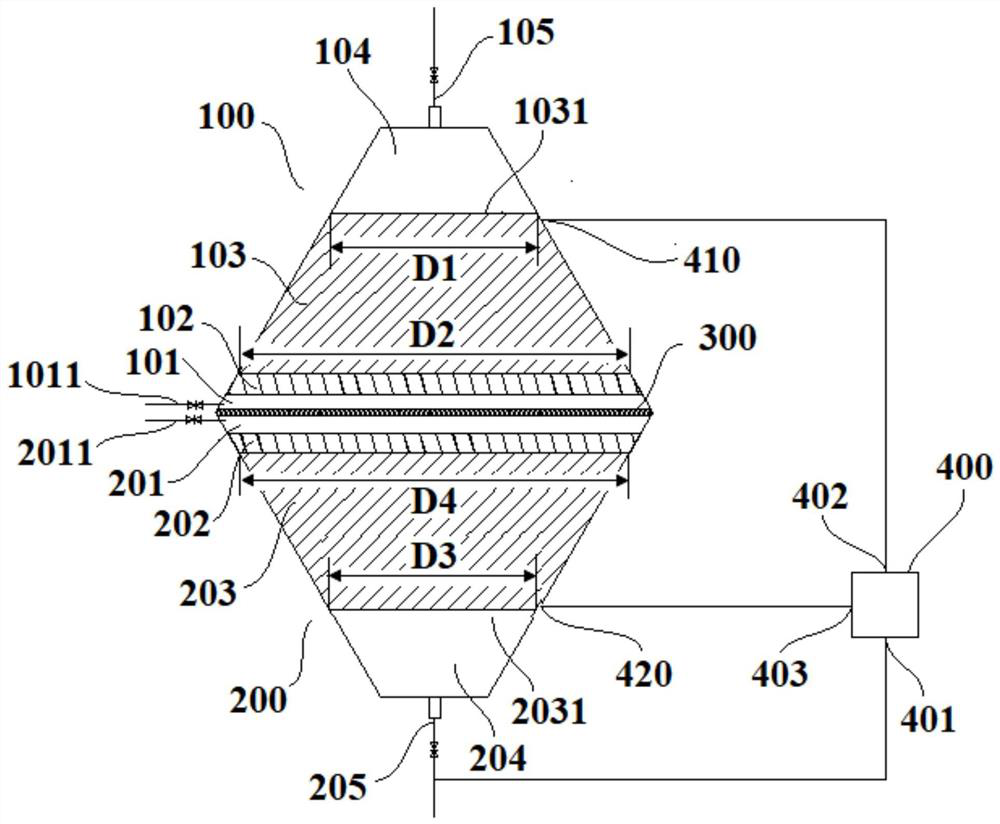

[0041]A conversion adsorption-desorption device of the present invention comprises an adsorption tower 100 and a desorption tower 200, the adsorption tower 100 is arranged above the desorption tower 200; the bottom of the adsorption tower 100 and the top of the desorption tower 200 are correspondingly arranged , between the adsorption tower 100 and the desorption tower 200, a partition 300 that allows the resin to pass through is provided; in the adsorption tower 100, along the direction from bottom to top, an adsorption water inlet channel 101, an adsorption layer 103, and an adsorption water outlet are sequentially arranged. Channel 104; the desorption tower 200 is sequentially provided with a desorption liquid inlet channel 201, a desorption layer 203 and a desorption liquid outlet channel 204 from top to bottom; with the direction from bottom to top as the positive direction, the adsorption layer 103 The cross-sectional area of a certain height h1 is S1, said S1=f 1 (h1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com