Mute drive chain system for motorcycle rear drive transmission and motorcycle

A technology for drive chains and motorcycles, which is applied in the direction of transmission chains, transmissions, and transmission parts, etc., and can solve the problems of low-noise personalized high-end motorcycles, increased transmission noise of the chain transmission system, and failure of speedometer sensors. and other problems to achieve the effect of eliminating the failure of the speedometer sensor, eliminating the dangerous risk of the chain detaching from the sprocket, and realizing the effect of silent transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

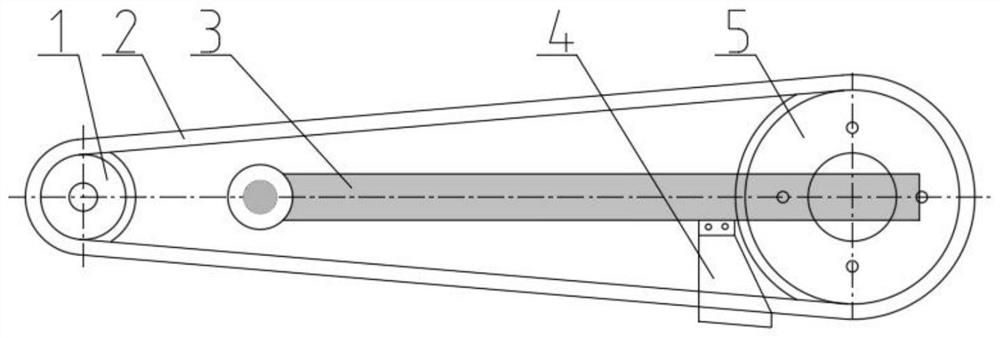

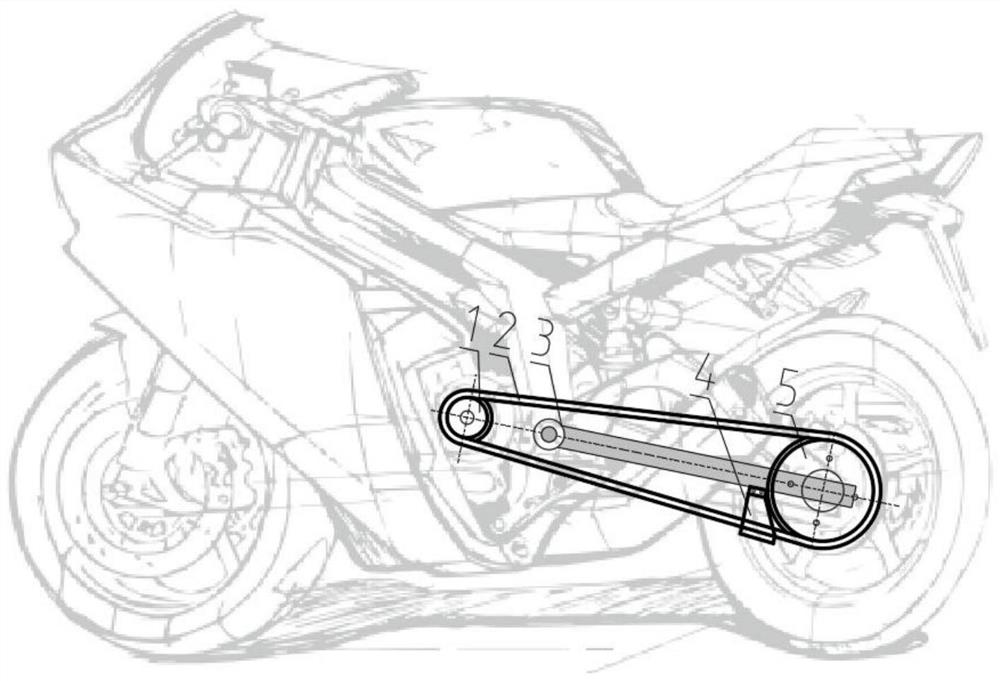

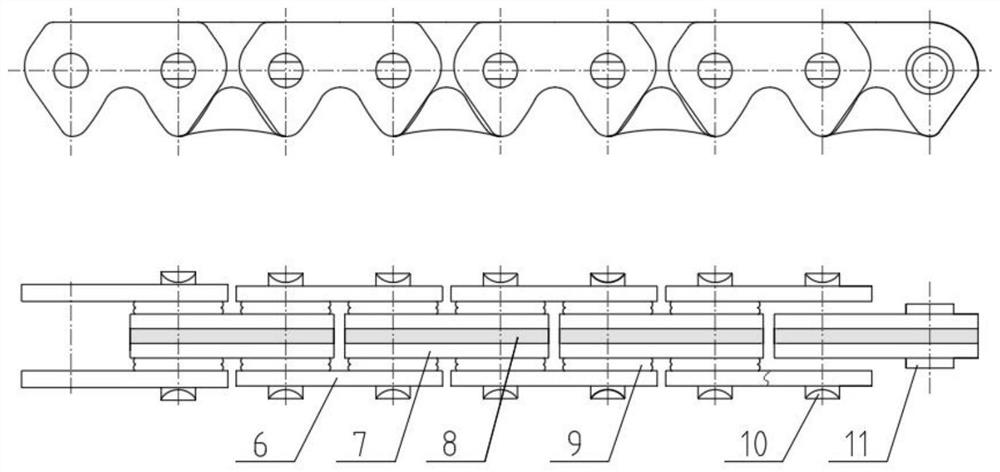

[0037] A silent drive chain system for motorcycle rear drive transmission, such as Figure 1~6 Shown, comprise small sprocket 1, large sprocket 5, and the silent driving chain 2 that transmission is connected between small sprocket 1 and large sprocket 5, described small sprocket 1 and the electric motor of motorcycle or engine The output shaft is detachably and fixedly connected, and the large sprocket 5 is detachably and fixedly connected with the rear wheel shaft of the motorcycle. The silent driving chain 2 is a toothed chain, including: an outer chain plate 6, an inner chain plate 7, and a guide plate 8. Pin shaft 10, sleeve 11 and shock-absorbing sealing ring 9; the sleeve 11 is in interference fit with the mounting holes of the inner chain plate 7 and guide plate 8, and forms an inner chain together with the inner chain plate 7 and guide plate 8 Section, the pin shaft 10 penetrates through the sleeve 11, and is clearance fit with the sleeve 11, the two ends of the pin s...

Embodiment 2

[0040] On the basis of Embodiment 1, this embodiment has made further improvements, specifically:

[0041] like Figure 1~6 As shown, the guide plate 8 is located in the middle of the outer surface of the sleeve 11, the inner chain plate 7 is symmetrically installed on both sides of the guide plate 8, and the shock-absorbing sealing ring 9 is sleeved on the end of the sleeve 11. , and the inner and outer end surfaces of the shock-absorbing sealing ring 9 respectively abut against the outer surface of the adjacent inner link plate 7 and the inner surface of the outer link plate 6 .

Embodiment 3

[0043] On the basis of Embodiment 2, this embodiment has made further improvements, specifically:

[0044] The meshing of the silent driving chain 2 with the small sprocket 1 and the large sprocket 5 is an internal and external compound meshing mechanism, or the meshing of the silent driving chain 2 and the large sprocket 5 adopts an internal meshing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com