Self-heat-setting type anti-freezing and anti-spalling valve

A self-heating, anti-expansion technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as valve damage, valve damage, valve bursting, etc., to extend service life, avoid condensation, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

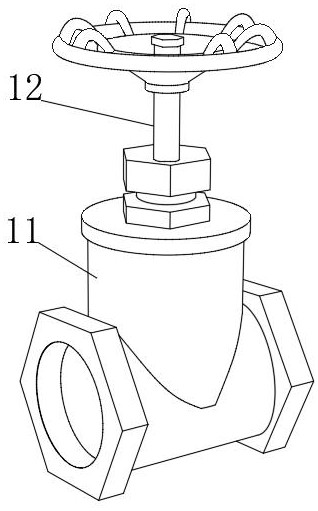

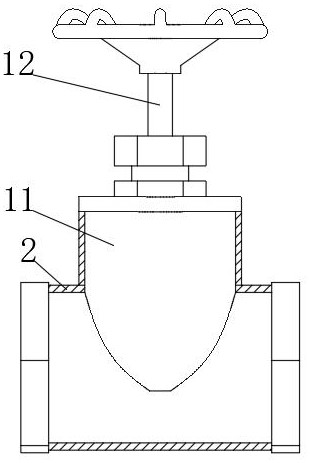

[0039] see Figure 1-2 , a self-condensing heat-resistant anti-freezing and anti-expansion valve, including a valve body 11, a valve stem 12 is installed on the valve body 11, and a self-heating coagulation sleeve 2 is wrapped on the outer surface of the valve body 11.

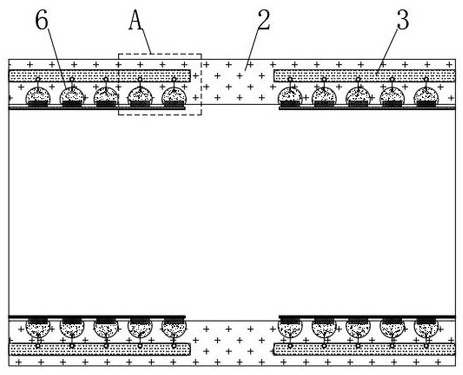

[0040] see Figure 3-4 , a in the figure represents thermal coagulation particles. There are multiple uniformly distributed annular self-heating chambers excavated inside the self-heating coagulation sleeve 2. A self-breaking water bag 3 is placed inside the self-breaking water bag 3. The interior of the self-breaking water bag 3 is saturated with water and self-heating The inner wall of the coagulation sleeve 2 is provided with a plurality of equalization nets corresponding to the annular self-heating cavity, and the homogenization net wraps the heat-conducting copper mesh 72 attached to the inner wall of the self-heating coagulation sleeve 2, a plurality of sets of evenly distributed heat-conduction rods 71 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com