Pair of quick optical cable stripping pliers

A technology of wire strippers and optical cables, which is applied in the direction of cable installation, cable installation devices, equipment for dismantling/armoring cables, etc., and can solve the problems of increased man-hours and costs, cable core damage, and uneven force applied to the height of the stripping tool and other problems, to achieve the effect of convenient stripping, uniform pressure, and improved stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

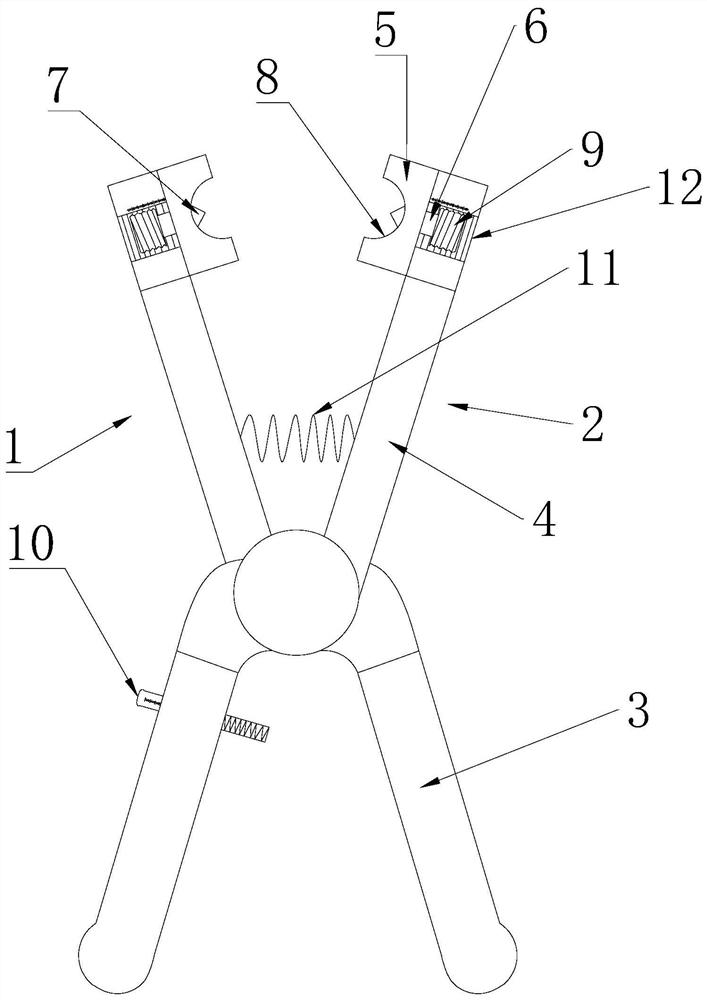

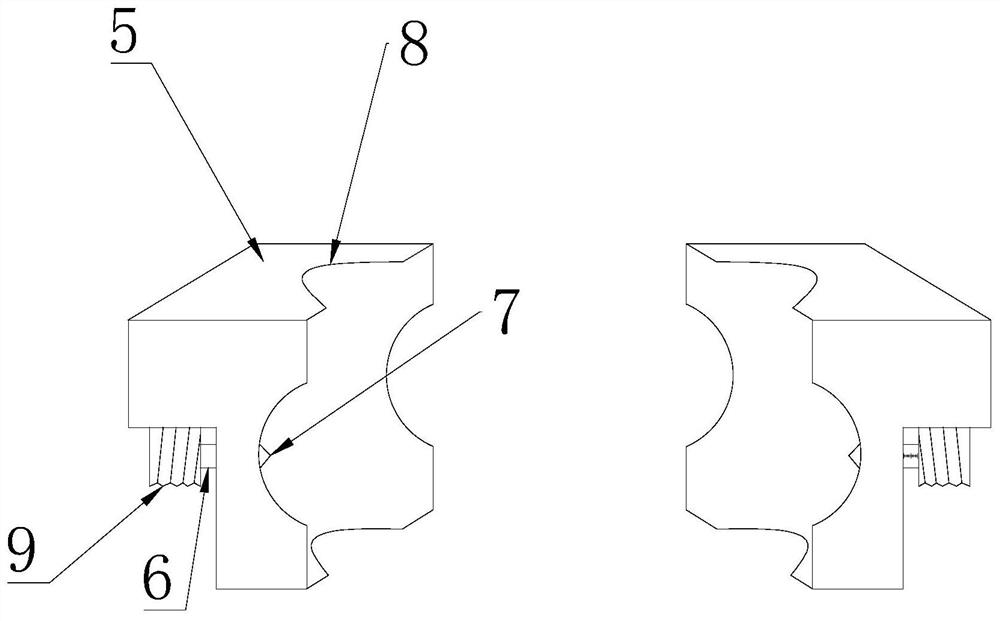

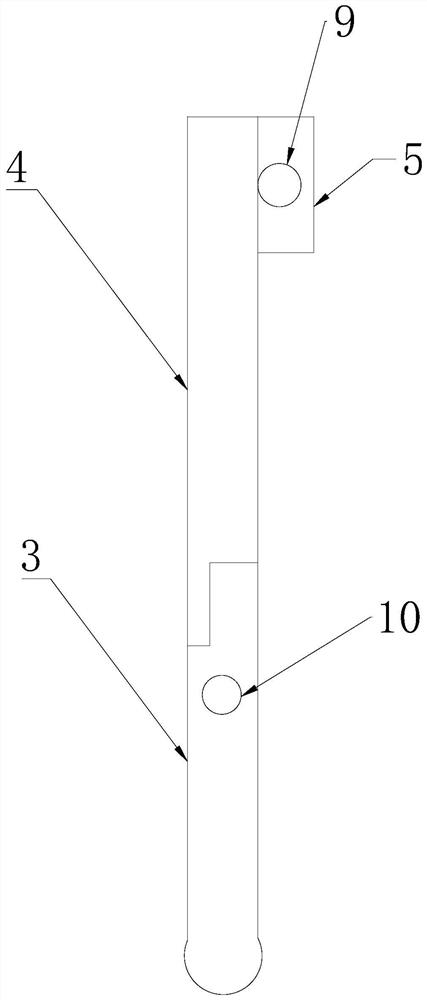

[0023] Such as Figure 1~3 In the shown quick stripping pliers for optical cables, the middle parts of the first pliers body 1 and the second pliers body 2 are staggered and hinged, and the first pliers body 1 and the second pliers body 2 include a holding section 3 and a working section 4. The head of the working section 4 is provided with a clamping block 5, and the two stripping knife structures are respectively socketed with the clamping block 5. The stripping knife structure includes a nut 9 fixing block 6 and a stripping knife 7, and the tail of the stripping knife 7 is fixed to the One end of the block 6 is fixedly connected, and the other end of the fixed block 6 is clamped with the nut 9. The nut 9 and the fixed block 6 can rotate relatively. , the abutment surface 12 is provided with an internal thread, the nut 9 is threadedly connected with the working end, the nut 9 is rotated, the nut 9 moves along the abutment surface 12, the fixed block 6 is pushed to move along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com