Robot gripper

A technology of robots and grippers, applied in the field of robotic equipment, can solve the problems of bulky terminal actuators, high assembly difficulty, and small displacement of clamping actions, so as to reduce the execution inertia of terminal actions, improve safety and stability, reduce The effect of small power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

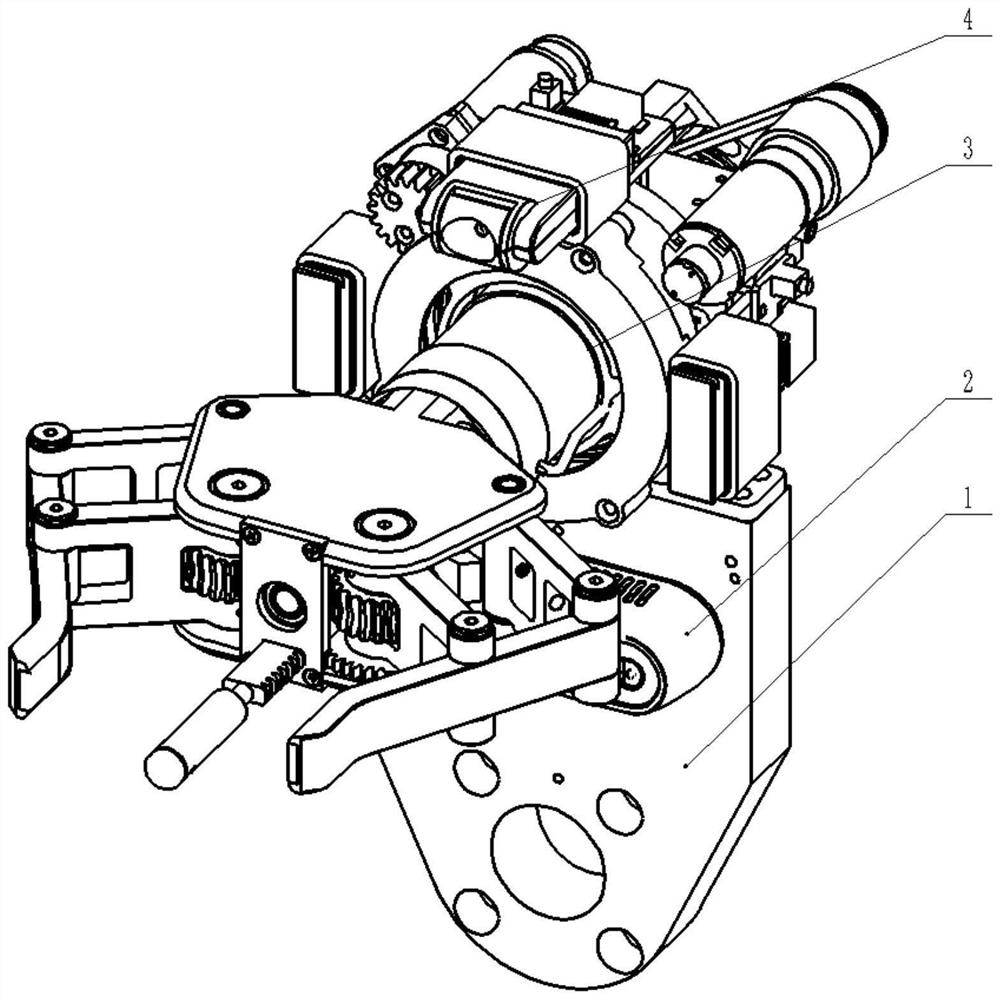

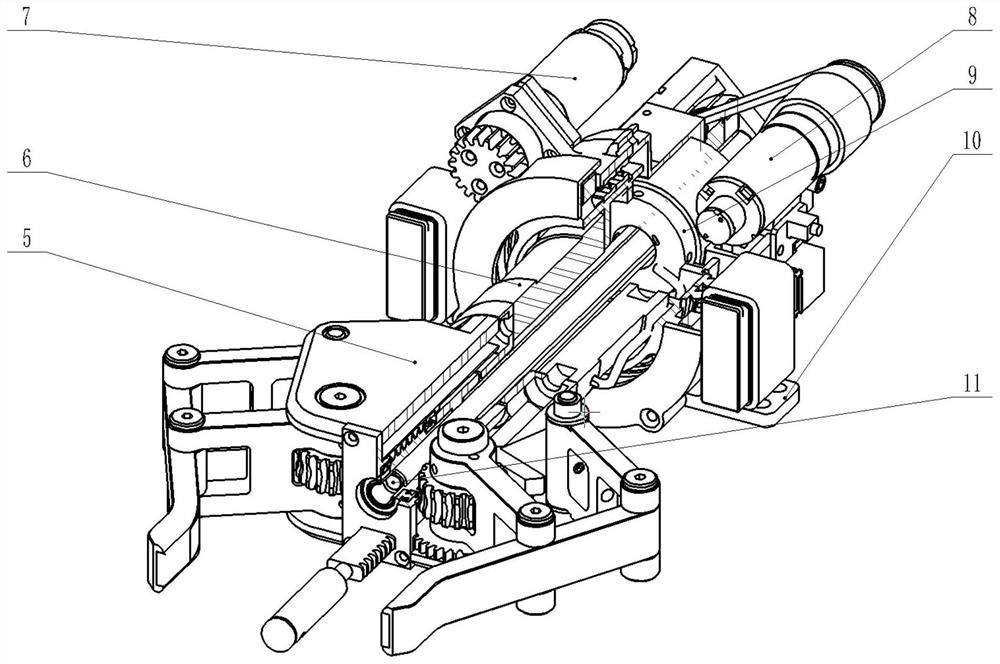

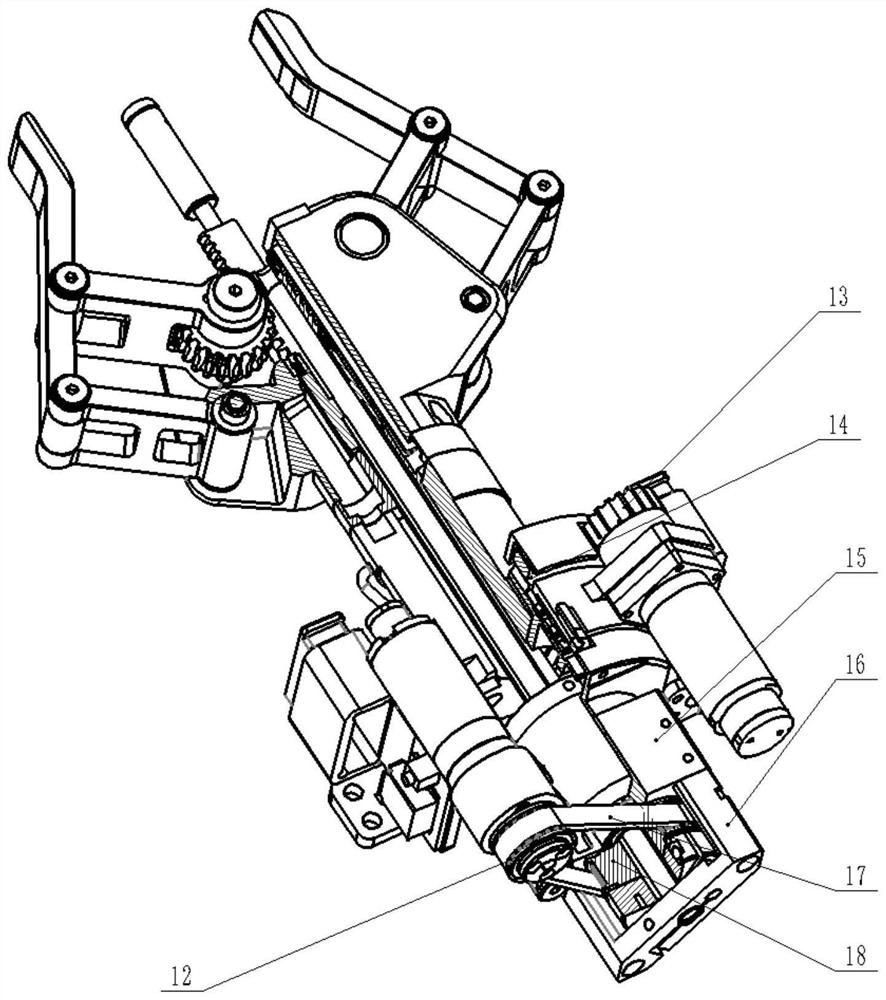

[0038] figure 1 It is the general assembly drawing of the robot gripper of the present invention. Such as figure 1 As shown, the robot gripper equipped with torque sensing and micro-angle monitoring of the present invention includes a mounting bracket 1 and a gripper assembly 3 installed on the mounting bracket 1, and a visual camera 2 is fixedly installed on the mounting bracket 1, and the visual camera 2 acquires The position information of the gripping object provides spatial positioning for the action of the gripper of the robot of the present invention. The installation bracket 1 is provided with a docking feature with the mechanical arm, which is used for fixed docking with the mechanical arm. The jaw assembly 3 is fixed and installed above the installation bracket 1 through the installation flange 10, and the installation bracket 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com