Automatic glass film pasting device

A glass film, sliding plate technology, used in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

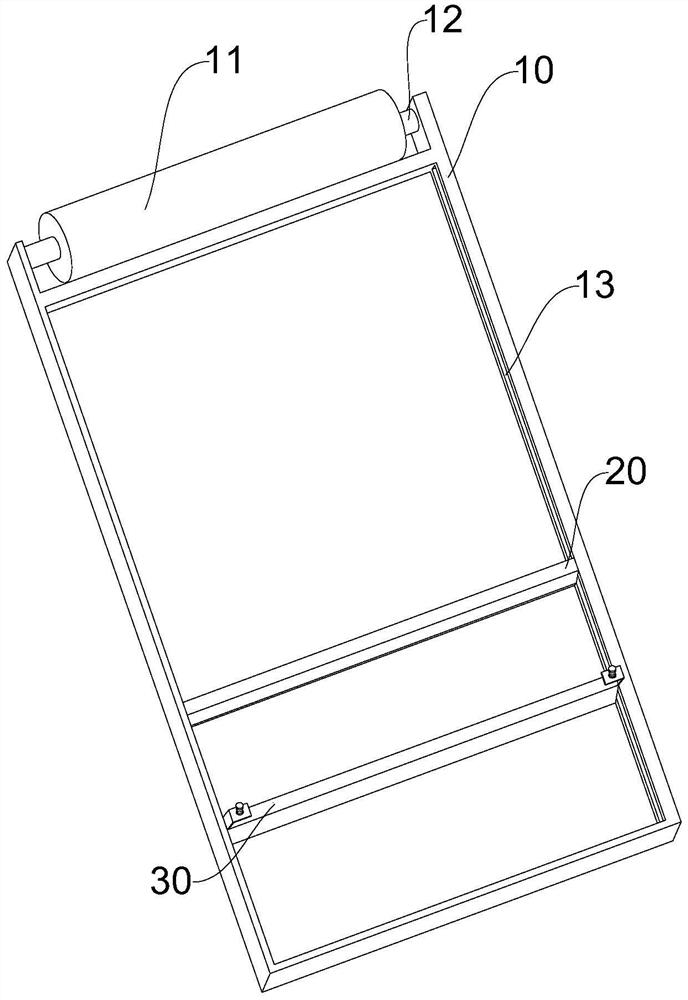

[0031] Such as Figure 1-5 As shown, it is a schematic structural view of an automatic glass film sticking device in a preferred embodiment of the present invention. The window frame 10 in this embodiment includes a roller 11, a roller 12, and a groove 13. The roller 11 and The roller 12 is rotatably connected, the roller 12 is rotatably connected to the groove 13, the groove 13 is symmetrically distributed with respect to the vertical center line of the window frame 10, and the groove 13 is slidably connected to the pressure assembly 20, The fixing assembly 30 is connected to the groove 13, and the pressure assembly 20 and the fixing assembly 30 are distributed in parallel with respect to the window frame 10;

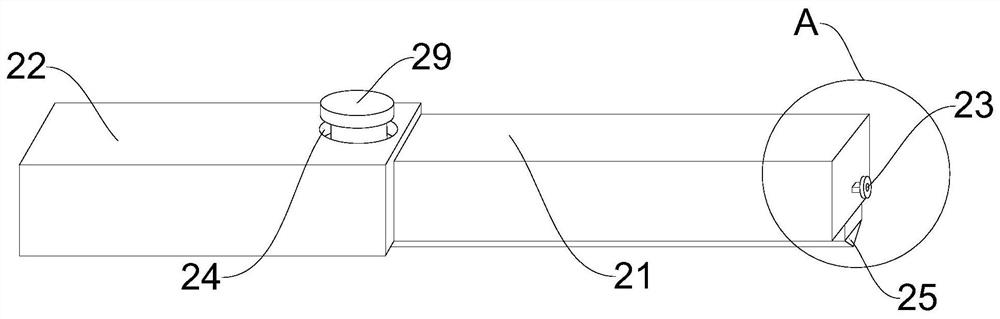

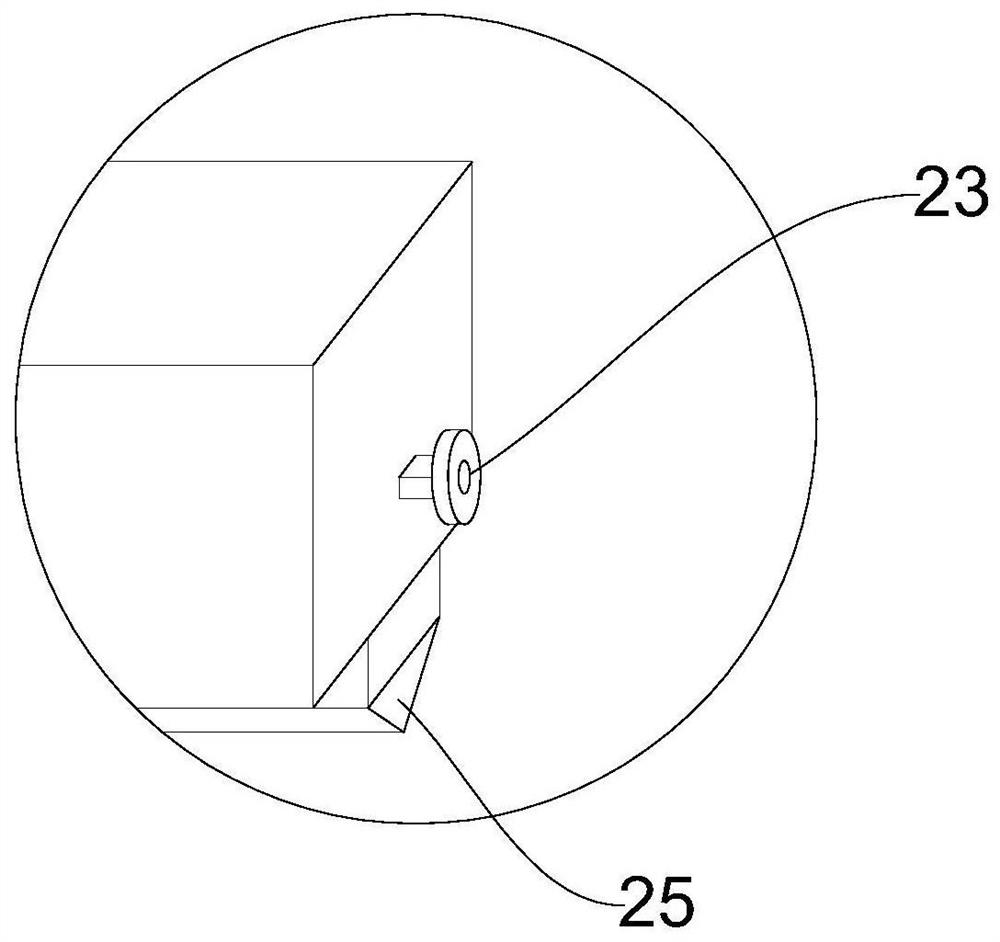

[0032] The pressure assembly 20 includes a sliding plate 21, a fixed plate 22 and a pulley 23, the sliding plate 21 is slidably connected with the fixed plate 22, the fixed plate 22 is a hollow structure, and a chute 26 is provided on the inner surface, so The two end...

Embodiment 2

[0036] Such as Image 6 with Figure 7 As shown, it is a structural schematic diagram of an automatic glass film sticking device in another preferred embodiment of the present invention. The fixing assembly 30 includes a folding plate 31 and a bottom plate 35, and the two ends of the upper end surface of the bottom plate 35 are provided with folding plate 31, the folded plate 31 is connected with the second fixed opening 32, the right side of the bottom plate 35 is provided with a pulley 34, the pulley 34 is slidingly connected with the groove 13, and the screw 33 connected inside the second fixed port 32;

[0037] On the basis of Embodiment 1, in the process of glass film sticking, the glass film is placed on the two ends of the fixing assembly 30, and the screw 33 is turned to make it move downwards in a spiral, so as to fix the glass film on the top and pull the fixing assembly 30 to the tail end of the window frame 10, thereby solving the problem that two operators are r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap