Embedded control surface clearance and skewness automatic detection method and equipment

An automatic detection, embedded technology, applied in the field of avionics, can solve the problems of low measurement accuracy, low reliability of measurement results, low measurement efficiency, etc., to improve test accuracy, improve versatility and flexibility, and achieve full automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

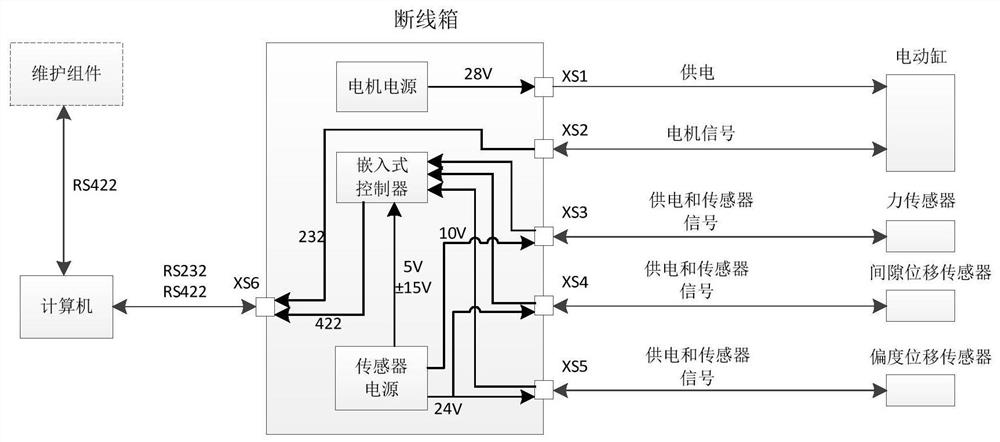

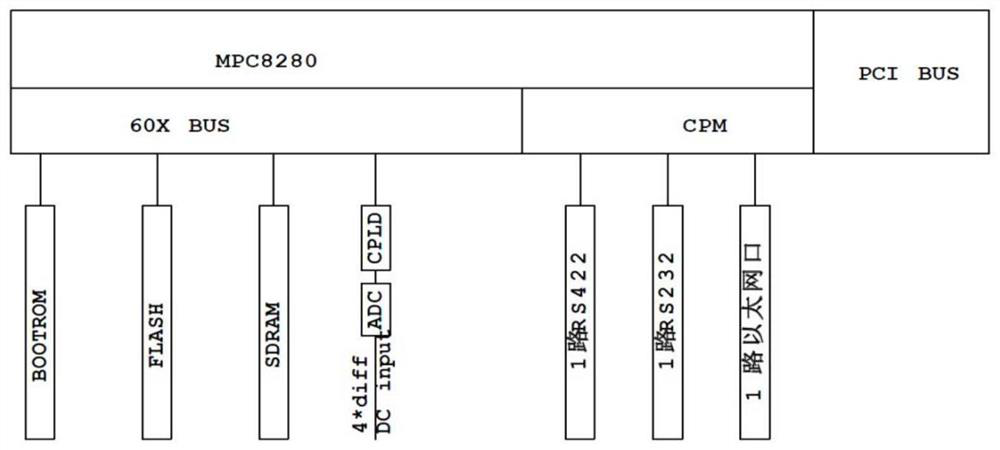

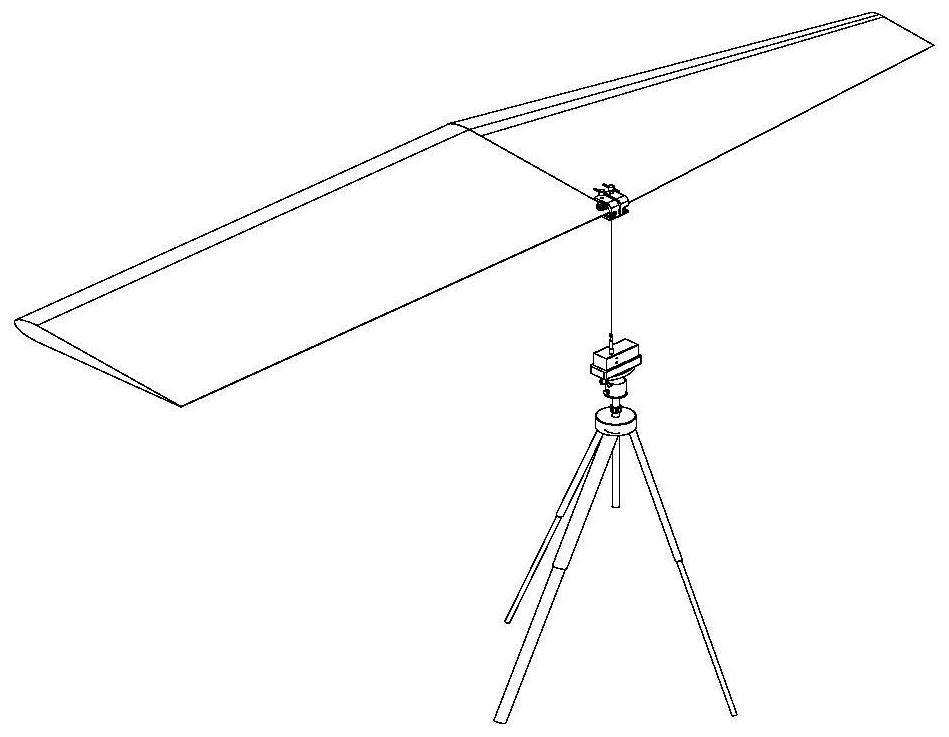

[0027]A method of embedded rudder face gap and amplifier automatic detection method and device in actual case are illustrated by a steering rudder gap and amplifier. Before performing the gap detection of the flake rudder, first, according tofigure 1 After all electrical connections are completed, open the "Motor Power" switch and "sensor power" switch to start the host computer. The upper machine sends a "self-test" instruction to the embedded controller. After the embedded controller completes the self-test, the self-test results are reported, the upper machine pops the text window, if the text content is "self-test success", it indicates that the equipment is self-test, can Continue test, if the text content is "CH X channel abnormality" X represents the corresponding channel number, the self-test failure is required. Then, the electric cylinder telescopia is then controlled by the upper machine, and the stroke of the electric cylinder is adjusted to the -2mm ~ + 2 mm scale posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com