Preparation method and application of catalyst for synthesizing hydroxyl-terminated trans-1, 4-polyisoprene polymer

A technology of polyisoprene and synthesis method, which is applied in the field of synthesizing hydroxyl-terminated trans-1, which can solve problems such as unsuccessful synthesis and achieve good regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

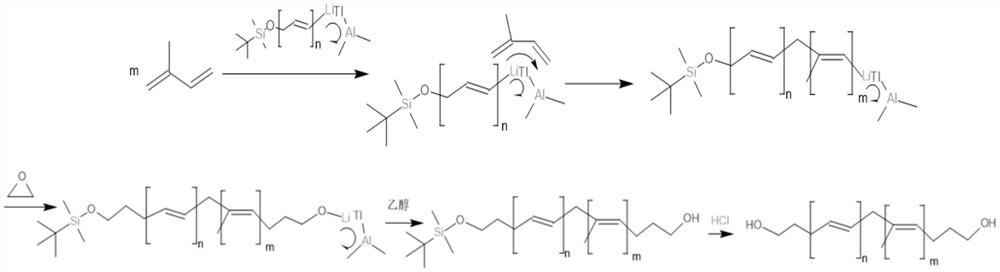

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Synthesis of hydroxyl-terminated trans-1, the preparation of 4-polyisoprene polymer catalyst

[0028] 4.1 Under an inert atmosphere, add component C triethylsilyloxypropyllithium into the solution of component D polymer grade butadiene in proportion, the reaction temperature is 10°C, and the reaction time is 10h to obtain a reaction solution;

[0029] 4.2 Keeping in an inert atmosphere, the component A supported titanium-based catalyst TiCl 4 / MgCl 2 , B Tripropylaluminum was added to the solution obtained in 4.1 according to the proportion, and reacted at 0° C. for 480 minutes to obtain a catalyst for synthesizing hydroxyl-terminated trans-1,4-polyisoprene polymer.

[0030] Wherein, the molar ratio of components A, B, C, and D in the reaction process is 1:1:5:1.

Embodiment 2

[0031] Example 2 Synthesis of Terminated Hydroxyl Trans-1, Preparation of 4-polyisoprene Polymer Catalyst

[0032] 4.1 Under an inert atmosphere, add component C tert-butyldiphenylsilyloxypropyllithium into the solution of component D polymer-grade isoprene in proportion, the reaction temperature is 50°C, and the reaction time is 1h to obtain reaction solution;

[0033] 4.2 Keeping in an inert atmosphere, the component A supported titanium-based catalyst TiCl 4 / MgCl 2 , B Triethylaluminum was added to the solution obtained in 4.1 according to the proportion, and reacted at 60° C. for 60 minutes to obtain a catalyst for synthesizing hydroxyl-terminated trans-1,4-polyisoprene polymer.

[0034] Wherein, the molar ratio of components A, B, C, and D in the reaction process is 1:10:10:20.

Embodiment 3

[0035] Example 3 Synthesis of hydroxyl-terminated trans-1,4-polyisoprene polymer catalyst preparation

[0036]4.1 Under an inert atmosphere, add component C tert-butyldimethylsilyloxypropyl lithium in proportion to the solution of component D polymer-grade isoprene, the reaction temperature is 30°C, and the reaction time is 5h, to obtain reaction solution;

[0037] 4.2 Keeping in an inert atmosphere, the component A supported titanium-based catalyst TiCl 4 / MgCl 2 , B Triisobutylaluminum was added to the solution obtained in 4.1 according to the proportion, and reacted at 30° C. for 270 minutes to obtain a catalyst for synthesizing hydroxyl-terminated trans-1,4-polyisoprene polymer.

[0038] Wherein, the molar ratio of components A, B, C, and D in the reaction process is 1:5:8:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com