Wire drawing process for preparing high-toughness antioxidant PP plastic wire

An anti-oxidation, high-toughness technology, applied in the field of plastic preparation, can solve the problems of affecting the mechanical properties of plastics, large amount of additives, cumbersome preparation process, etc., and achieve the effects of rapid dissipation, enhanced toughness, and stable network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

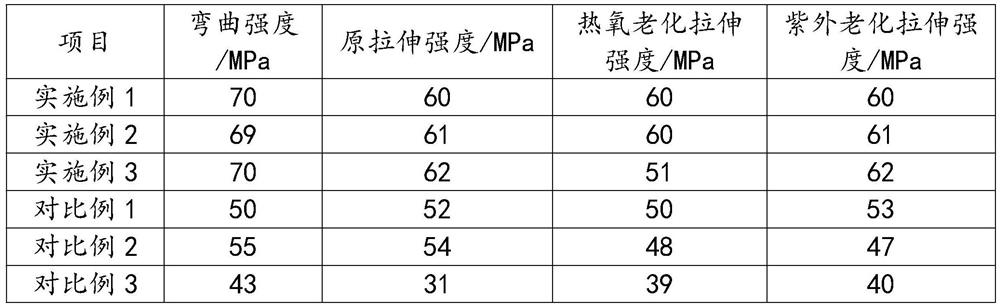

Examples

Embodiment 1

[0030] A wire drawing process for the preparation of high-toughness and oxidation-resistant PP plastics, comprising the following steps:

[0031] The first step, prepare the following raw materials by weight: 200 parts of polypropylene, 50 parts of modified basalt fiber, 20 parts of epoxy resin, 5 parts of dicumyl hydroperoxide, 10 parts of dimethyl phthalate, diethylene 5 parts of triamine, 1 part of composite antioxidant, 1 part of initiator and 5 parts of plasticizer;

[0032] The second step is to add polypropylene, epoxy resin, dimethyl phthalate and dicumyl hydroperoxide into the reaction kettle, raise the temperature to 280°C at a heating rate of 5°C / min, and stir at a speed of 200r / min After 30 minutes, add modified basalt fiber, composite antioxidant, initiator, plasticizer and diethylenetriamine successively in the reactor, keep stirring for 20 minutes to obtain the mixture;

[0033] The third step is to transfer the mixture obtained in the second step to a screw ex...

Embodiment 2

[0048] A wire drawing process for the preparation of high-toughness and oxidation-resistant PP plastics, comprising the following steps:

[0049] The first step, prepare the following raw materials in parts by weight: 210 parts of polypropylene, 70 parts of modified basalt fiber, 25 parts of epoxy resin, 10 parts of dicumyl hydroperoxide, 12 parts of dimethyl phthalate, diethylene 8 parts of triamine, 2 parts of composite antioxidant, 2 parts of initiator and 8 parts of plasticizer;

[0050] The second step is to add polypropylene, epoxy resin, dimethyl phthalate and dicumyl hydroperoxide into the reaction kettle, raise the temperature to 290°C at a heating rate of 5°C / min, and stir at a speed of 250r / min After 45 minutes, add modified basalt fiber, composite antioxidant, initiator, plasticizer and diethylenetriamine successively in the reaction kettle, keep stirring for 30 minutes to obtain the mixture;

[0051] The third step is to transfer the mixture obtained in the secon...

Embodiment 3

[0066] A wire drawing process for the preparation of high-toughness and oxidation-resistant PP plastics, comprising the following steps:

[0067] The first step, prepare the following raw materials in parts by weight: 220 parts of polypropylene, 80 parts of modified basalt fiber, 30 parts of epoxy resin, 12 parts of dicumyl hydroperoxide, 15 parts of dimethyl phthalate, diethylene 10 parts of triamine, 3 parts of composite antioxidant, 3 parts of initiator and 10 parts of plasticizer;

[0068] In the second step, add polypropylene, epoxy resin, dimethyl phthalate and dicumyl hydroperoxide into the reaction kettle, raise the temperature to 300°C at a heating rate of 5°C / min, and stir at a speed of 300r / min After 60min, add modified basalt fiber, composite antioxidant, initiator, plasticizer and diethylenetriamine successively in the reactor, keep stirring for 40min to obtain the mixture;

[0069] The third step is to transfer the mixture obtained in the second step to a screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com