Printing UV ink as well as preparation method and application thereof

A technology of ink and monomer, which is applied in the field of printing UV ink and its preparation, can solve the problems of UV ink, such as irritating and unpleasant smell, affecting the use of users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

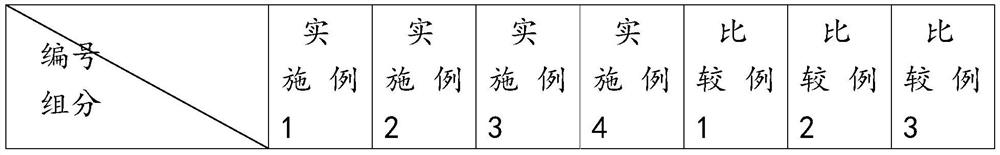

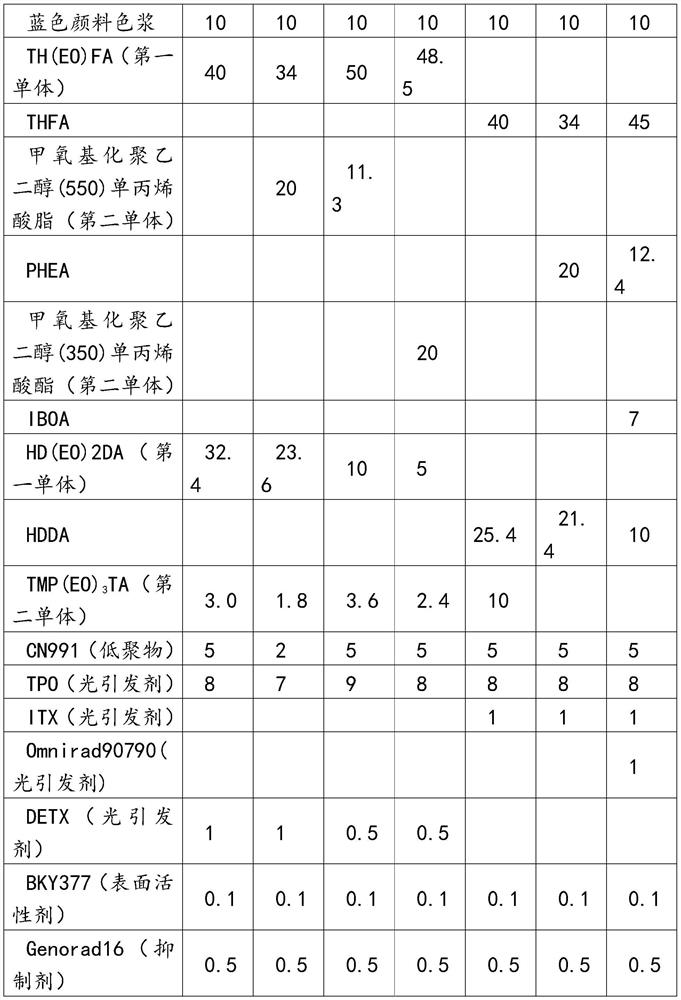

Examples

preparation example Construction

[0032] The printing UV ink preparation method provided by the present invention is used to prepare the above-mentioned printing UV ink, and the preparation method comprises the following steps:

[0033] S1. Mix the pigment, the dispersant and the first monomer in proportion to the sand mill, and use the 0.3mm zirconium beads to grind for 6h-8h at a speed of 800rpm-1200rpm to obtain the pigment paste;

[0034] S2. Mix the first monomer and the second monomer evenly, then add a photoinitiator to dissolve completely, add oligomers and auxiliary agents, stir for 1h to 2h, and obtain a mixed solution;

[0035] S3. Add the pigment paste into the mixed liquid in S2, disperse at a speed of 400 rpm to 600 rpm for 1 h to 2 h, and filter with a 1 μm filter element to obtain UV ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com