Deformation control device and method in ultrasonic rolling process of RV reducer cycloidal gear

An ultrasonic rolling and deformation control technology, applied in the field of deformation control devices, can solve problems such as fatigue failure, easy deformation, and wear of contact pairs, and achieve uniform control of clamping force, reduced workload, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

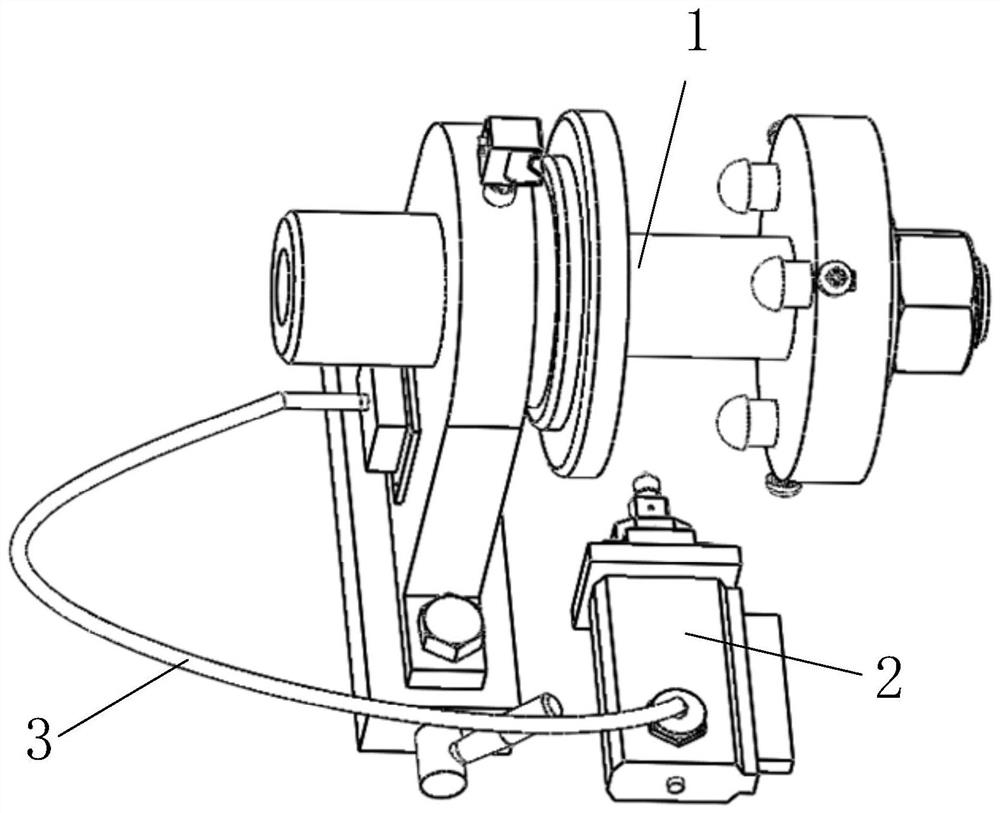

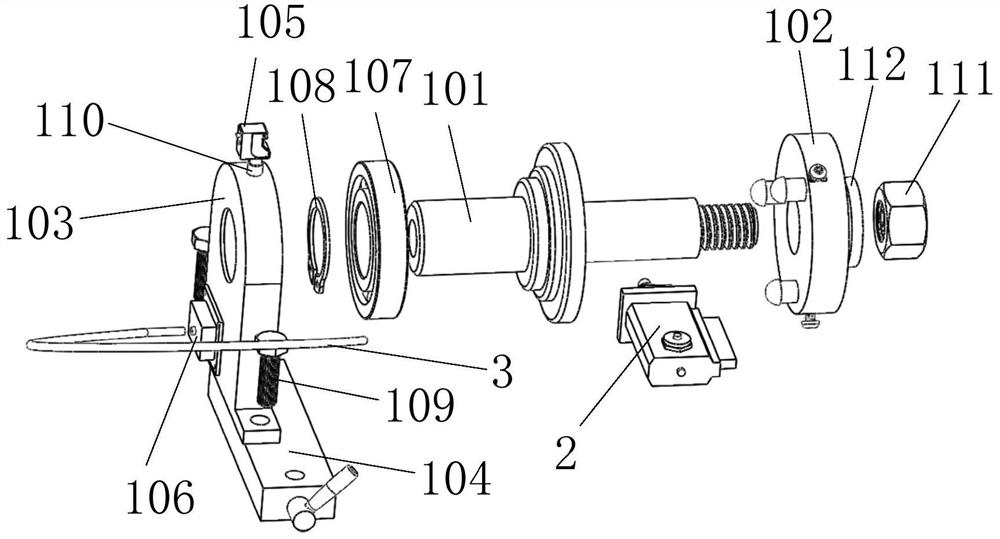

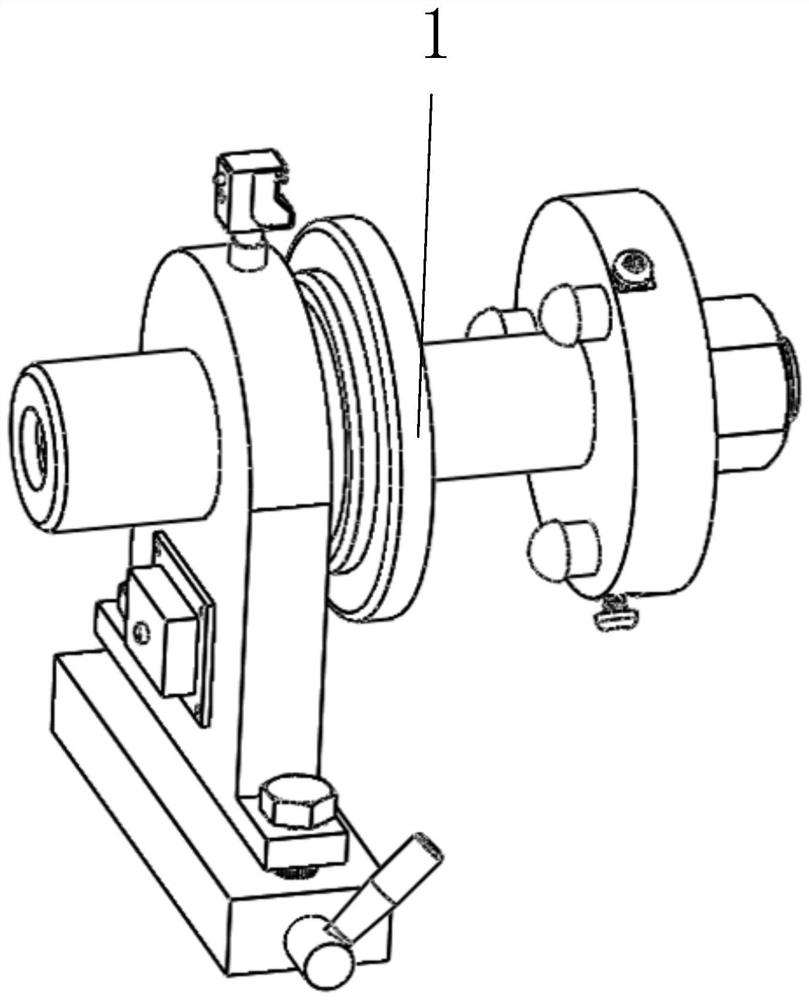

[0036] Such as Figure 1 to Figure 5 As shown, this embodiment provides a deformation control device in the ultrasonic rolling process of the RV reducer cycloid wheel, the device includes a fixture assembly 1, an ultrasonic rolling tool 2 and a signal transmission line 3, and the fixture assembly 1 includes Positioning element 101, clamping block 102, bearing seat 103, permanent magnet suction block base 104, profile sensor 105 and controller 106, rolling bearing 107 is installed in bearing seat 103, rolling bearing 107 is equipped with retaining ring 108, and bearing seat 103 height Adjustably connected to the permanent magnet block base 104, the positioning element 101 has a first end and a second end opposite to the first end, the first end of the positioning element 101 is fixedly connected to the rolling bearing 107, and passes through the bearing seat 103, The second end of the positioning element 101 is detachably connected to the clamping block 102, the profile sensor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com