A preparation method of a three-dimensional woven closed cavity structure and its prefabricated parts

A closed, three-dimensional machine technology, applied in textiles, fabrics, textiles and papermaking, etc., can solve problems such as limited anti-extrusion range, and achieve the effects of improving anti-extrusion, optimizing molding methods, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

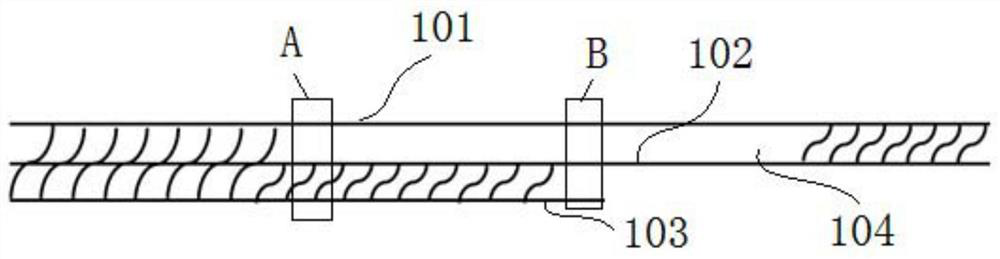

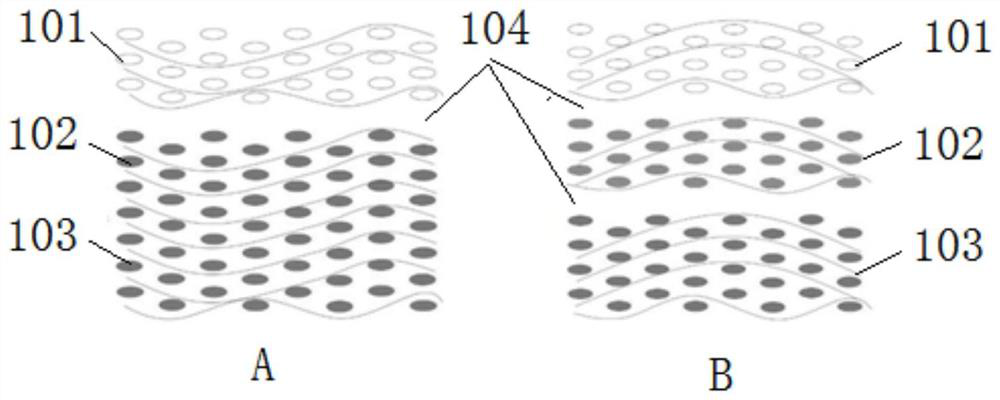

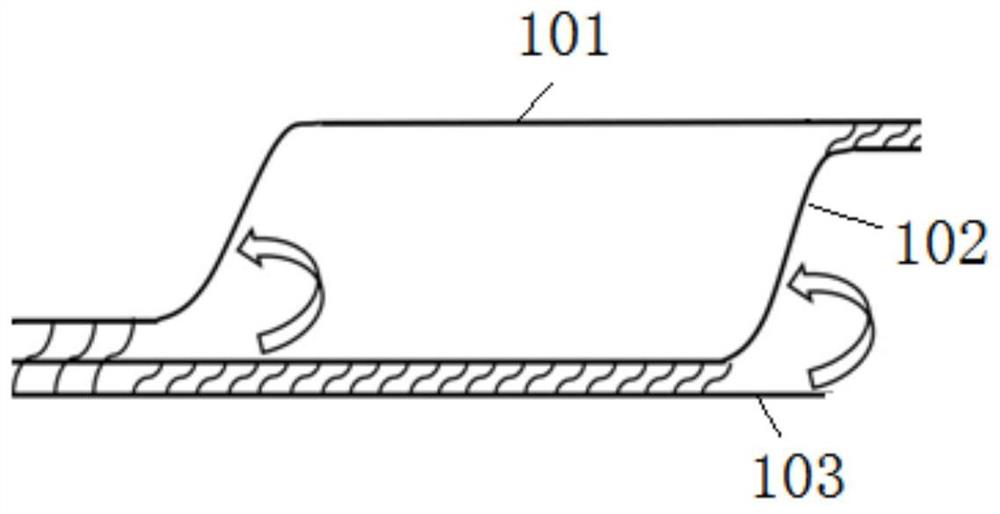

[0044]The invention relates to a preparation method of a three-dimensional woven closed cavity structure, which comprises three-layer structure weaving, preparation of the cavity structure and sealing of the opening end of the cavity structure. Specifically, it includes using a three-dimensional weaving method to form a cavity structure with open ends on both sides; it also includes setting a closed extension extending from one edge of the opening end during the process of forming the cavity structure by a three-dimensional weaving method 105, the yarn connected to the opposite sides of the free end in the closed extension 105 is the weft yarn 204 to be replaced; the edge of the adjacent closed extension 105 on the open end also forms a filling warp yarn 205 extending from it; then Move the free end of the closed extension 105 towards the open end to cover all or part of the open end, and finally replace the weft yarn 204 to be replaced in the closed extended section 105 with t...

Embodiment 2

[0061] A three-dimensional woven flat plate preform, including the cavity structure prepared by the method for preparing a three-dimensional woven closed cavity structure described in Example 1.

[0062] A carbon fiber-reinforced composite cavity structure, which is obtained by using the above-mentioned three-dimensional woven flat plate prefabricated part, injecting resin and curing at high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com