Gear tooth profile measuring device based on line structured light

A technology of measuring equipment and line structured light, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of cumbersome calibration and debugging process, low efficiency, low accuracy, etc., and achieve the effect of high precision, small size and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

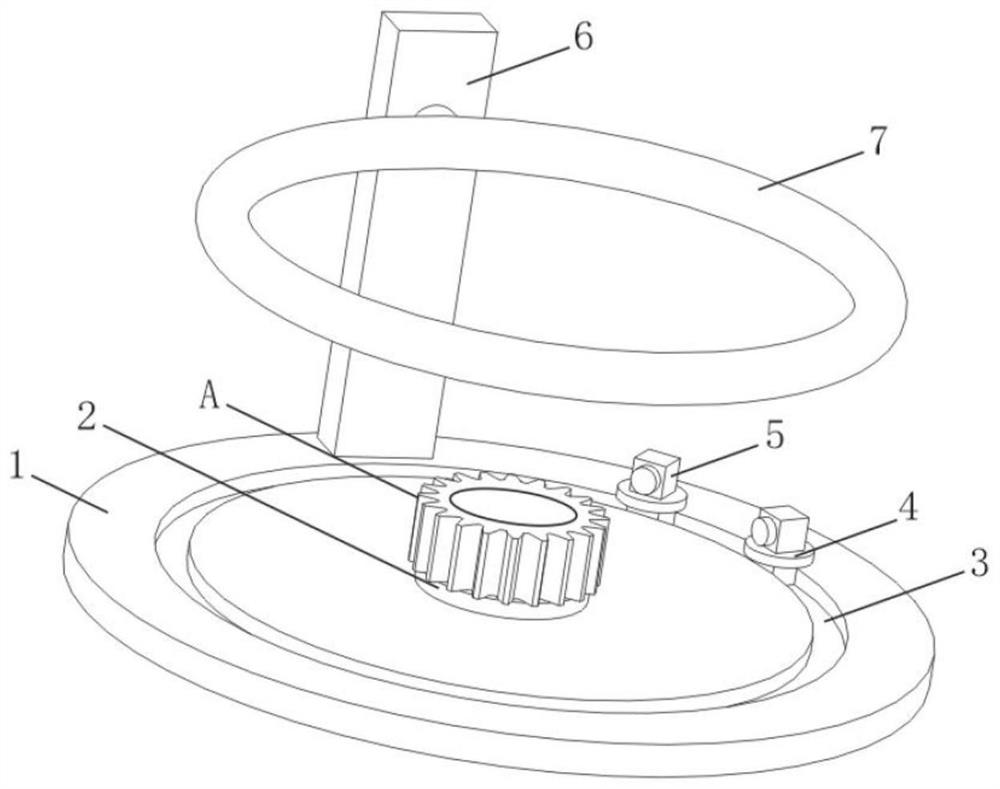

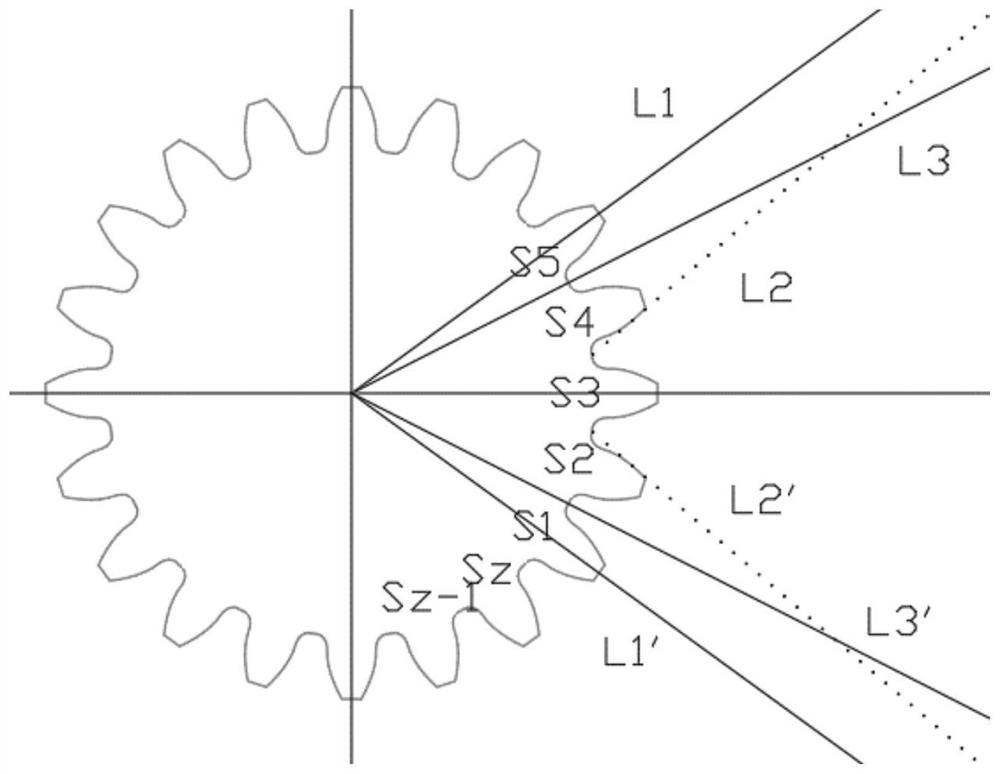

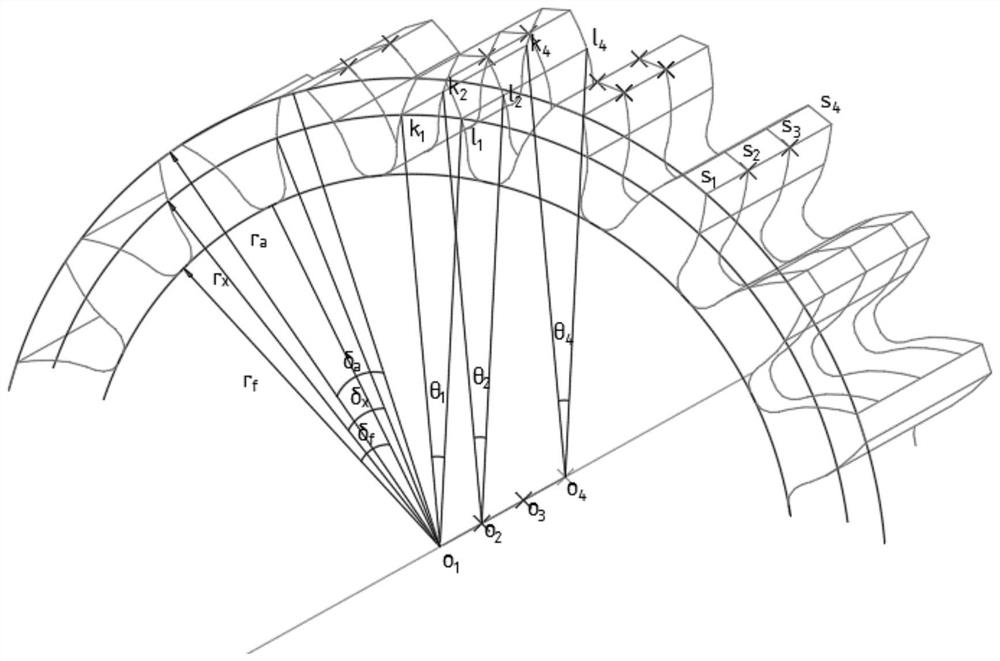

[0021] Such as figure 1 The shown gear tooth profile measurement equipment based on line structured light includes a workbench 1, a gear holder installed on the workbench 1, and a ring guide rail 3 arranged around the gear holder, and the ring guide rail 3 is provided with Two camera mounts 4 that can slide along the ring guide rail 3, a camera 5 is arranged on the camera mount 4, a ring laser 7 is installed above the gear holder, and the ring laser 7 is fixed on the gear holder The central axis of the tested gear A is concentric.

[0022] The present invention adopts two camera mounting tables 4 that can drive the camera 5 to rotate while rotating along the measured gear A, so that the camera 5 can adjust the relative position of the camera 5 to the gear teeth at the current position while rotating around the central axis of the measured gear A. Angle, can complete the measurement of various parameters such as gear tooth thickness, base circle radius, involute tooth profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com