Composite expansion film, preparation method and application thereof

A technology of adhesive layer and temperature-resistant layer, applied in the field of composite intumescent film and its preparation, can solve the problems of narrowing of intumescent film film width, potential safety hazards, unqualified products, etc., and achieve excellent expansion performance, high expansion, excellent The effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

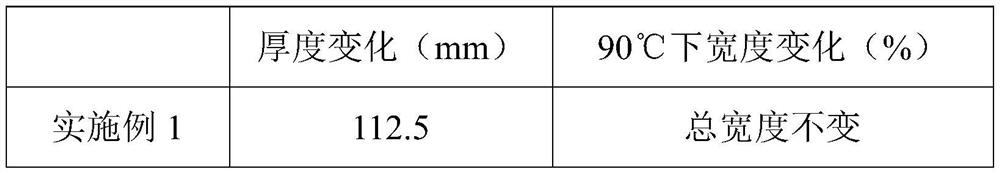

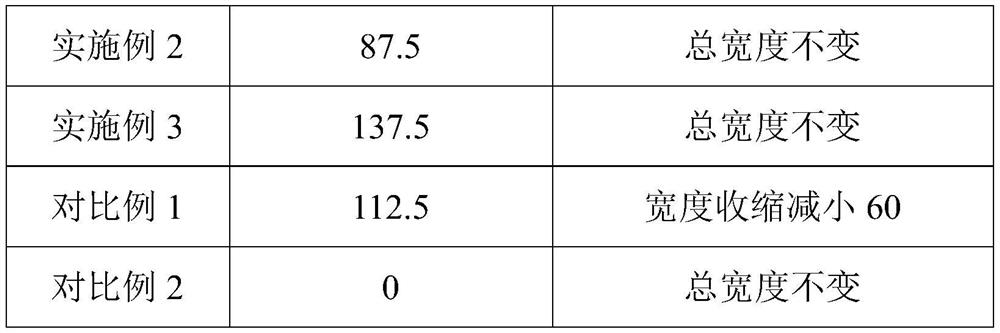

Embodiment 1

[0040] A composite expansion film, comprising a base layer (polystyrene (Foshan Dupont Hongji Film Co., Ltd., 45 μm OPS)) with a thickness of 45 μm, a first adhesive layer with a thickness of 3 μm (mass ratio of 1:2:4) Polyacrylate slurry obtained by mixing color paste (Nitto Denko Co., Ltd., phthalocyanine blue), curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) and acrylate (Nitto Denko Co., Ltd., acrylic glue for tape) ), a temperature-resistant layer (polyethylene terephthalate (Foshan Dupont Hongji Film Co., Ltd., 8 μm PET) with a thickness of 8 μm, and a thermal expansion coefficient of 6×10 -6 / K) and a second adhesive layer with a thickness of 3 μm (color paste (Nitto Denko Co., Ltd., phthalocyanine blue) with a mass ratio of 1:2:4, curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) Polyacrylate slurry obtained by mixing with acrylate (Nitto Denko Co., Ltd., acrylic glue for adhesive tape);

[0041] Its preparation method comprises the following ste...

Embodiment 2

[0045] A composite expansion film, comprising a base layer (polystyrene (Foshan Dupont Hongji Film Co., Ltd., 45 μm OPS)) with a thickness of 35 μm, a first adhesive layer with a thickness of 2 μm (mass ratio of 1:3:6) Polyacrylate slurry obtained by mixing color paste (Nitto Denko Co., Ltd., phthalocyanine blue), curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) and acrylate (Nitto Denko Co., Ltd., acrylic glue for tape) ), a temperature-resistant layer (polyimide (Foshan Dupont Hongji Film Co., Ltd., 12 μm PI film) with a thickness of 6 μm, and a thermal expansion coefficient of 3×10 -6 / K) and a second adhesive layer with a thickness of 2 μm (color paste (Nitto Denko Co., Ltd., phthalocyanine blue) with a mass ratio of 1:3:6, curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) Polyacrylate slurry obtained by mixing with acrylate (Nitto Denko Co., Ltd., acrylic glue for adhesive tape);

[0046] Its preparation method is identical with embodiment 1.

Embodiment 3

[0048] A composite expansion film, comprising a base layer (polystyrene (Foshan Dupont Hongji Film Co., Ltd., OPS of 55 μm)) with a thickness of 55 μm, a first adhesive layer (with a mass ratio of 1:2:4) with a thickness of 6 μm Polyacrylate slurry obtained by mixing color paste (Nitto Denko Co., Ltd., phthalocyanine blue), curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) and acrylate (Nitto Denko Co., Ltd., acrylic glue for tape) ), a temperature-resistant layer (polyethylene terephthalate (Nitto Denko Co., Ltd., acrylic adhesive for tape) with a thickness of 12 μm, and a thermal expansion coefficient of 6×10 -6 / K) and a second adhesive layer with a thickness of 6 μm (color paste (Nitto Denko Co., Ltd., phthalocyanine blue) with a mass ratio of 1:2:4, curing agent (Taiwan Changchun Chemical Co., Ltd., BR-20SE) Polyacrylate slurry obtained by mixing with acrylate (Nitto Denko Co., Ltd., acrylic glue for adhesive tape);

[0049] Its preparation method is identical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com