Motor rotor structure

A technology of motor rotor and motor shaft, which is applied in the manufacture of motor generators, stator/rotor body, magnetic circuit shape/style/structure, etc., which can solve the force that affects the normal operation and use of the whole machine, and the axial force Small size, large amount of elastic rubber used, etc., to achieve the effect of improving life, concentricity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

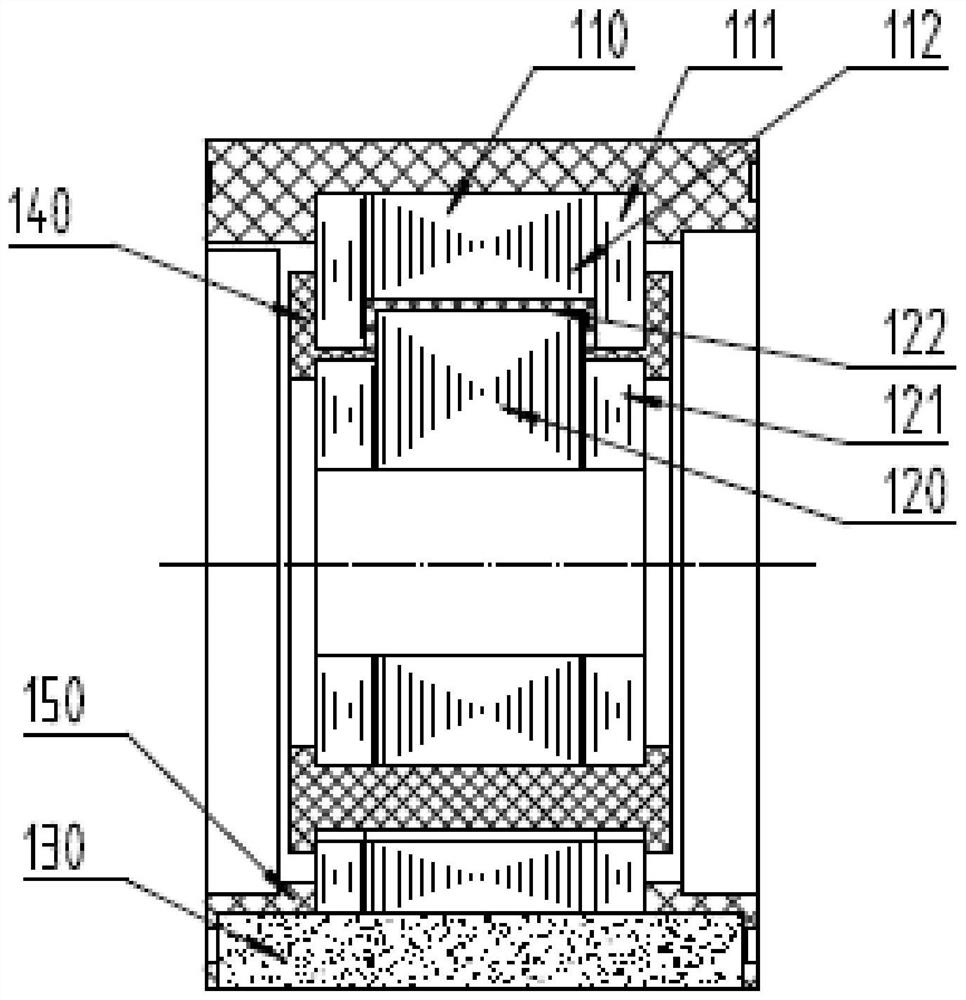

[0037] A motor rotor structure, including a motor shaft, also includes:

[0038] The inner rotor core 120 is sleeved on the outer periphery of the motor shaft;

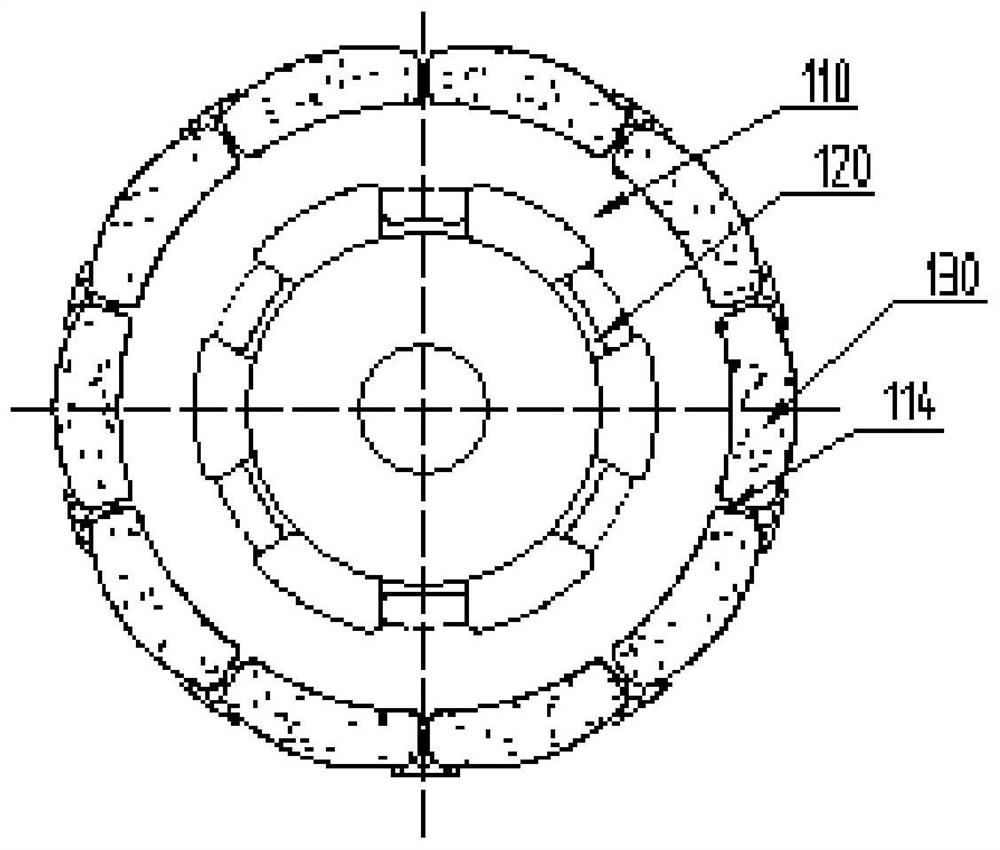

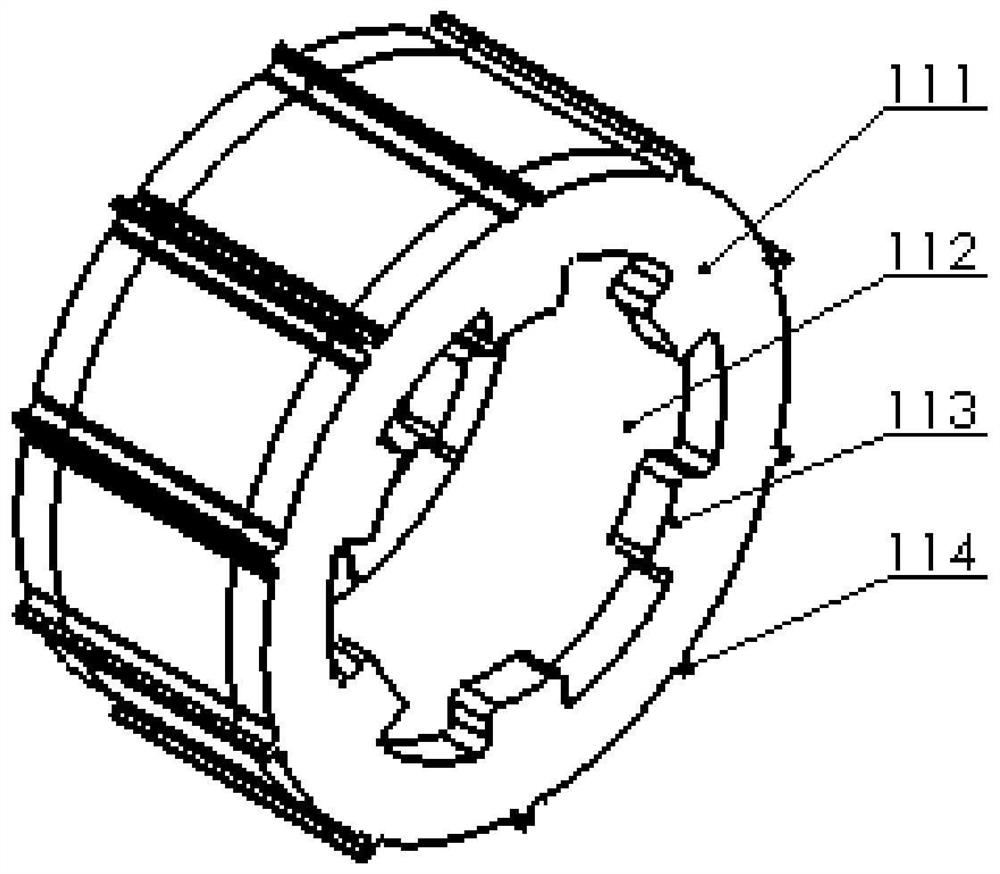

[0039] The outer rotor core 110 is sleeved on the outer periphery of the inner rotor core 120;

[0040] There is a gap between the inner rotor core 120 and the outer rotor core 110, and the gap is filled with injection rubber 140 for connecting and forming the inner rotor core 120 and the outer rotor core 110;

[0041] The limiting ribs 114 are arranged on the outer surface of the outer rotor core 110, the outer surface of the outer rotor core 110 is provided with a number of limiting ribs 114, and the plurality of limiting ribs 114 are evenly distributed on the outer rotor core the outer surface of 110;

[0042] The permanent magnet 130 is installed between the adjacent limiting ribs 114 by engaging.

[0043] The contact position between the limiting rib 114 and the permanent magnet 130 is covered with injection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com