Method of creating wafer shape data

A data-based, wafer-based technology, applied to measuring devices, instruments, electrical components, etc., can solve problems such as the inability to visualize the shape of wafers, and achieve the effect of reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

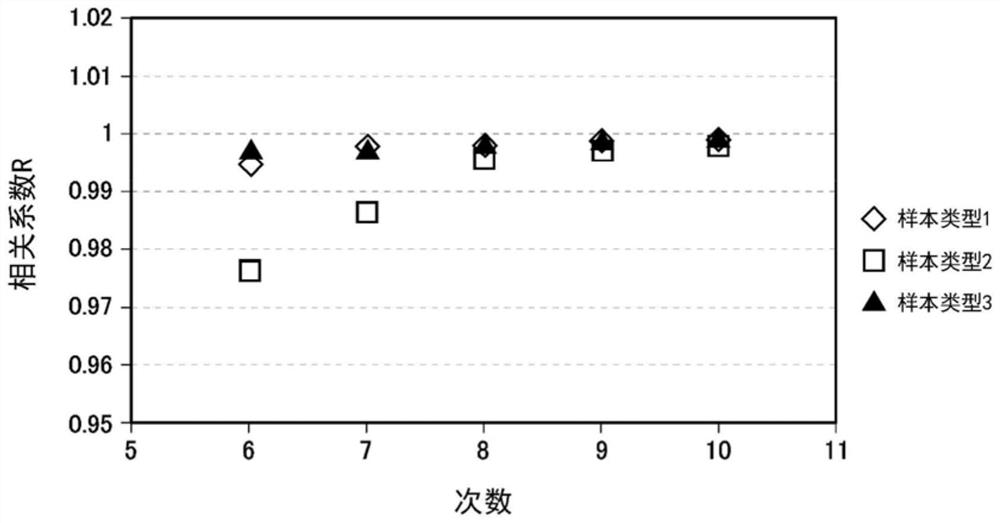

[0047] Investigate the relationship between polynomial degrees and correlation coefficients. Specifically, three silicon wafers (hereinafter referred to as wafers) having a diameter of 300 mm were prepared, and the thickness profile of each wafer was measured with a flatness measuring machine (Wafer Sight 2) manufactured by KLA-Tencor. In addition, Wafer Sight 2 is a measuring machine based on the principle that light is incident on the wafer, and the wafer is measured by the number and pitch of interference fringes generated by the optical interference of the reflected light from the wafer and the reflected light from the reference plane. The displacement of the surface.

[0048] Using the offline analysis software (OASys) manufactured by KLA-Tencor, the file (wnt file) of the measurement result output from Wafer Sight 2 was converted into a thickness measurement value in polar coordinates with the wafer center as the origin, and the converted Measured shape data is output a...

Embodiment 2

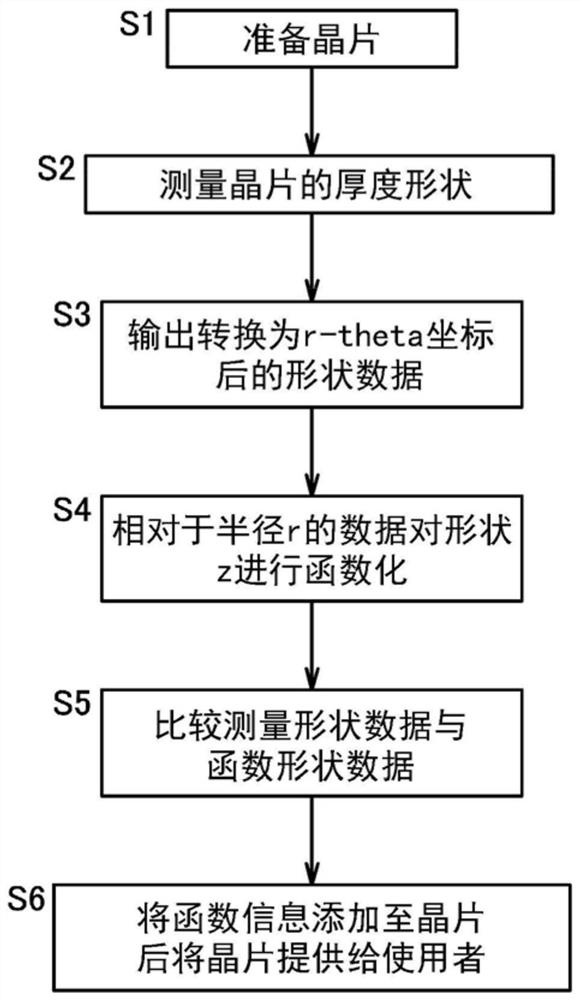

[0054] Prepare 15 silicon wafers (hereinafter referred to as wafers) with a diameter of 300mm, and each wafer according to figure 1 The step of functionization is performed, and the thickness map obtained from the obtained function is compared with the thickness map output from the measuring machine. Specifically, the thickness profile of each wafer was measured with a flatness measuring machine (Wafer Sight 2) manufactured by KLA-Tencor.

[0055] Using offline analysis software (OASys) manufactured by KLA-Tencor, the measurement result file (wnt file) output from Wafer Sight 2 is converted into a thickness measurement value in polar coordinates with the wafer center as the origin, and the converted measurement The shape data is output as a csv file. In the output measurement state data, the scale pitch in the θ direction (division angle θ1) is set to 1 degree, and the scale pitch in the r direction is set to 0.2 mm.

[0056] For each piece of measured shape data, approximat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com