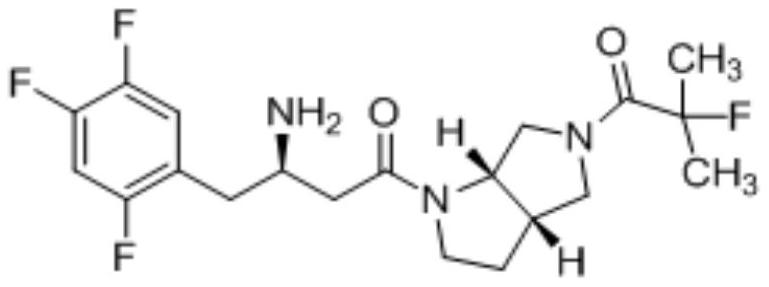

Pharmaceutical composition taking metformin or pharmaceutical salts thereof and omarigliptin or pharmaceutical salts thereof as active ingredients

A technology of metformin and metformin hydrochloride, which is applied in the directions of organic active ingredients, medical preparations containing active ingredients, drug combinations, etc., can solve problems such as research reports on the combination of antidiabetic drugs without ausagliptin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

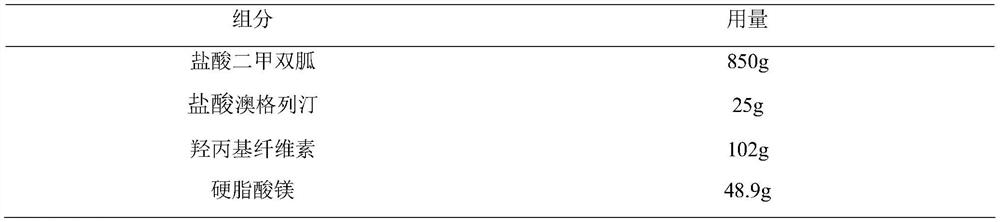

[0022] Example 1 Metformin Hydrochloride and Alogliptin Hydrochloride Tablets

[0023]

[0024] Preparation:

[0025] Pass metformin hydrochloride and alogliptin hydrochloride through a 60-mesh sieve respectively, then mix metformin hydrochloride, hydroxypropyl cellulose and alogliptin hydrochloride evenly, granulate and dry in a fluidized bed, pass through a 30-mesh sieve for granulation, and add Magnesium stearate is mixed evenly, and a suitable die is selected to compress the tablet to obtain final product.

[0026] A suitable coating material is selected for the above-mentioned compressed tablet to obtain a coated tablet, which can be a film-coated tablet, an enteric-coated tablet, or the like.

Embodiment 2

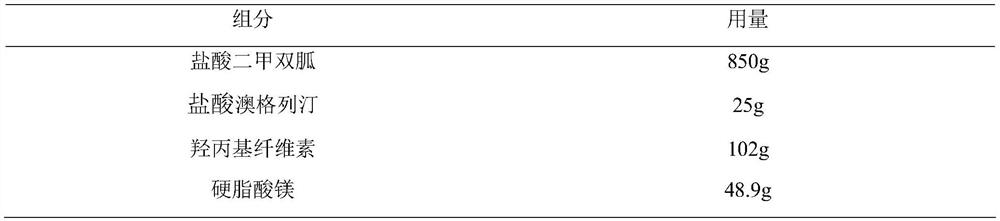

[0027] Example 2 Metformin Hydrochloride and Alogliptin Hydrochloride Capsules

[0028]

[0029] Preparation:

[0030] Pass metformin hydrochloride and alogliptin hydrochloride through a 60-mesh sieve respectively, then mix metformin hydrochloride, hydroxypropyl cellulose and alogliptin hydrochloride evenly, granulate and dry in a fluidized bed, pass through a 30-mesh sieve for granulation, and add The magnesium stearate is evenly mixed, filled, and obtained.

[0031] The capsule shell used for filling is an ordinary capsule shell.

Embodiment 3

[0032] Embodiment 3 Metformin Hydrochloride and Alogliptin Hydrochloride Dispersible Tablets

[0033]

[0034] Preparation:

[0035] Metformin hydrochloride, alogliptin hydrochloride, and microcrystalline cellulose were passed through 80-mesh sieves, mixed evenly, and 75% ethanol solution was added to prepare soft materials, granulated through 20-mesh sieves, dried, and granulated through 20-mesh sieves. Add the remaining auxiliary materials and mix evenly, select a suitable die to compress the tablet, and it is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com