Preparation method and application of thermochromic film based on hollow VO2 nanoparticles

A nanoparticle and thermochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of low visible light transmittance, low refractive index, insufficient transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

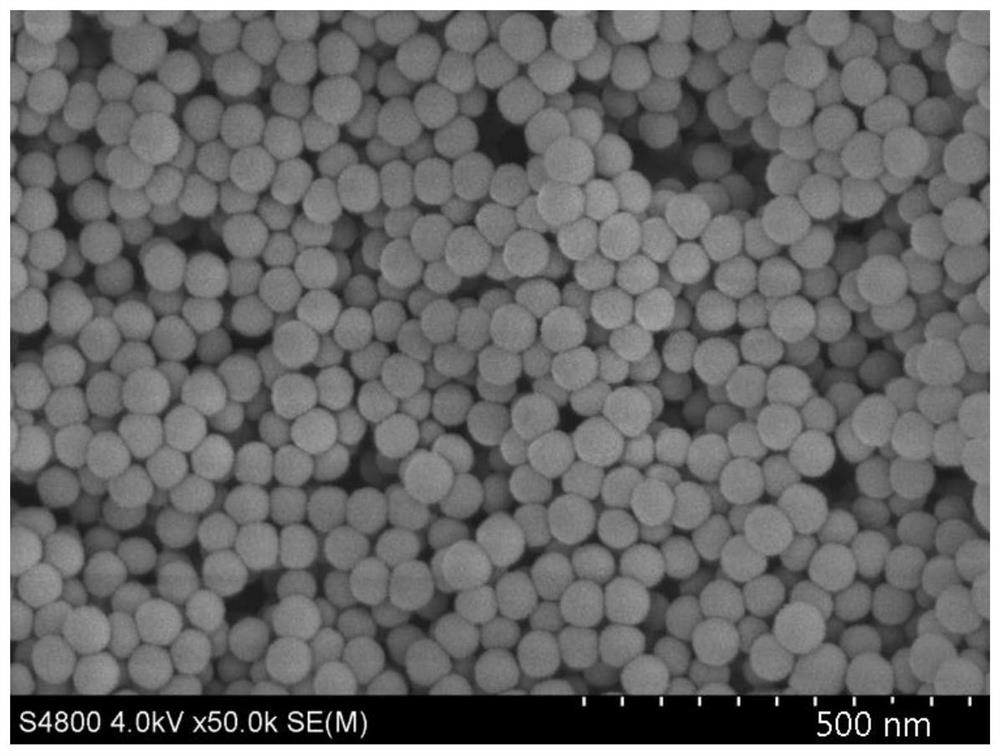

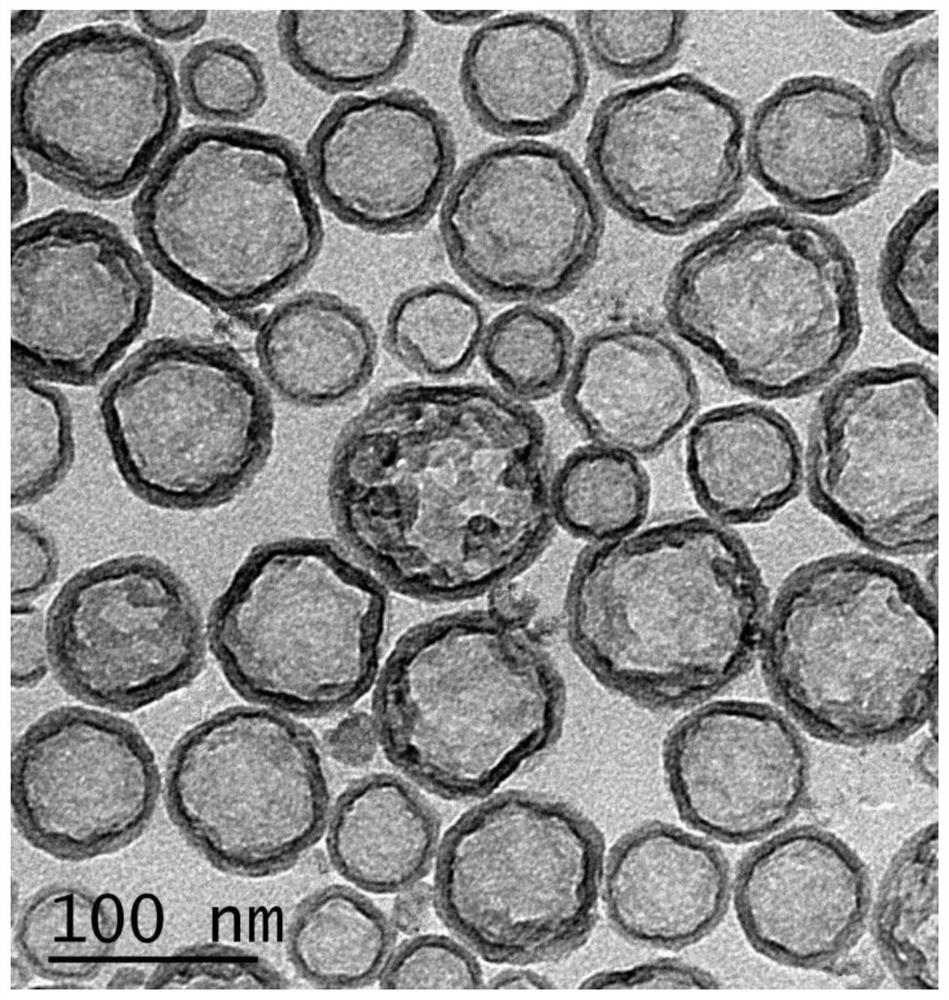

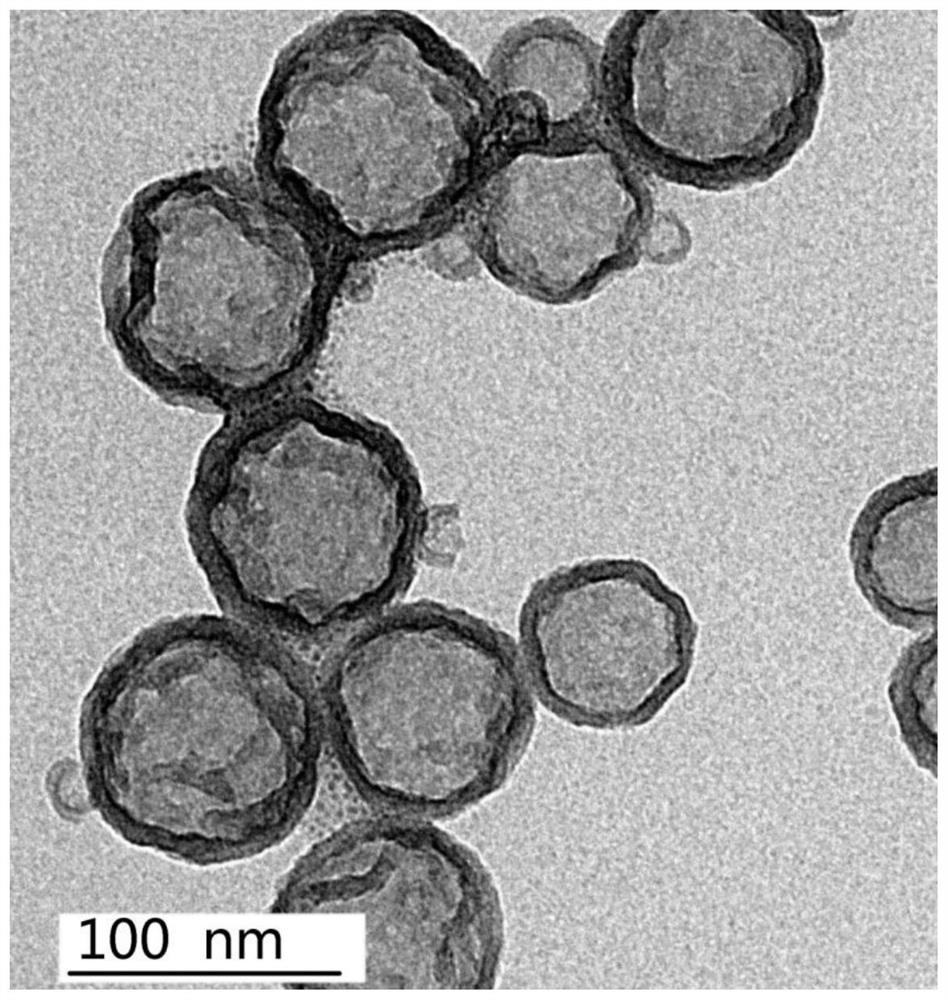

[0040] like Figure 1 to Figure 10 As shown, the invention disclosed based on hollow VO below 100nm 2 Methods and applications of thermochromic thin films of nanoparticles, and hollow VO below 100nm 2 Methods for the preparation of nanoparticles.

[0041] The hollow VO below 100nm used for the glass substrate in the present invention 2 The preparation method of the thermochromic thin film of nanoparticle, specifically as follows:

[0042] 1. Configure hollow VO 2 Coating solution

[0043] 1.1 Material: Hollow VO 2 Nano powder, ethanol, polyvinylpyrrolidone (PVP);

[0044] 1.2 method: the hollow VO 2 Disperse the nanopowder in an ethanol solvent with a mass fraction of 1-5wt%, stir for 30-60min, add 0.2-0.5wt% PVP to improve the film-forming property of the coating solution, and stir for 1h to obtain a coating solution.

[0045] 2. Plating hollow VO 2 Thermochromic Film

[0046] Before coating, place quartz glass, K9 glass, and ultra-clear glass in ethanol for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com