Opposite-pull screw for building brick-concrete composite wall and mold system and method

A composite wall and pair-pulling screw technology, which is applied to the on-site preparation of building components, walls, buildings, etc., can solve the problems of low mortar plumpness, inability to use external walls, and restricted construction methods, and achieve reliable bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

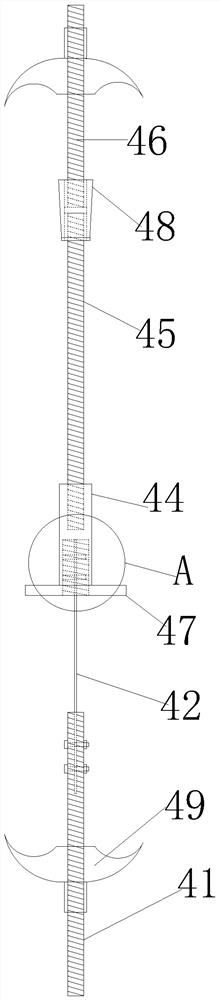

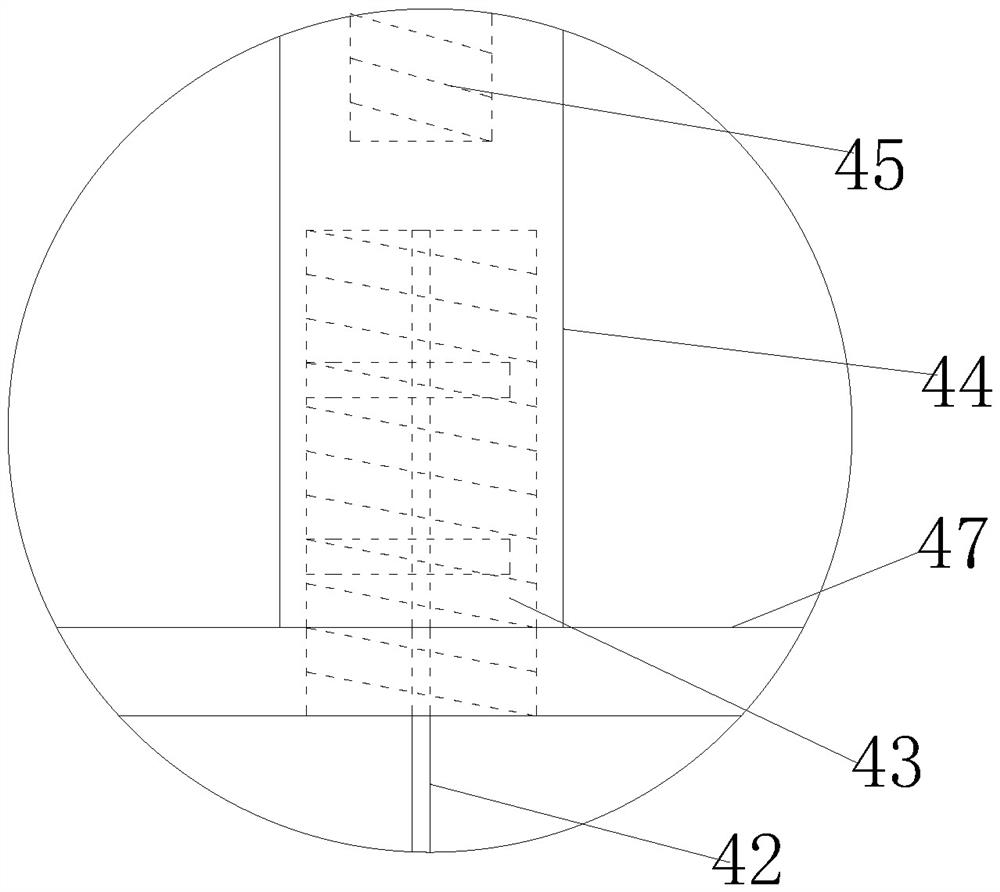

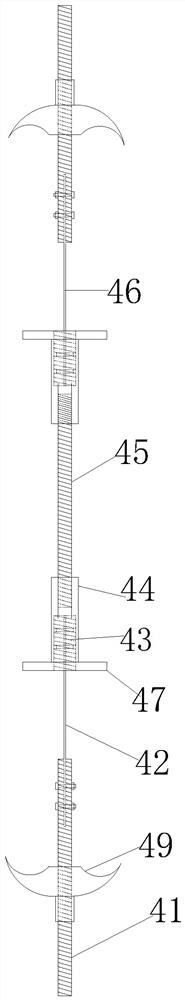

[0038] Such as Figure 1-3 As shown, a kind of pull screw used for building brick-concrete composite wall is used for building the wall body in which facing brick layer 3 and reinforced concrete layer 2 are superimposed, including the brick joint inserted in the brick joint of facing brick layer 3 Strip 42, the indwelling screw 45 inserted in the reinforced concrete layer 2, and the turnover screw located on both sides of the brick-concrete composite wall; the brick joint insert 42, the indwelling screw 45, and the turnover screw are coaxially arranged and detachably connected as one . If the wall has a face brick layer 3, use Figure 5 Shown contains a brick seam insert 42 and a set of tensioning screw 4 of the compression member. If the wall has two brick layers 3, then use Image 6 Shown contains two brick seam inserts 42 and the opposite pull screw rod 4 of two sets of compression members. The accessories of these two kinds of pull screw rods 4 are common and can be fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com