Speed control one-way valve

A technology of one-way valve and speed control valve, which is applied in the direction of valve device, valve details, valve housing structure, etc., to reduce complexity and realize the effect of direct drive and direct control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

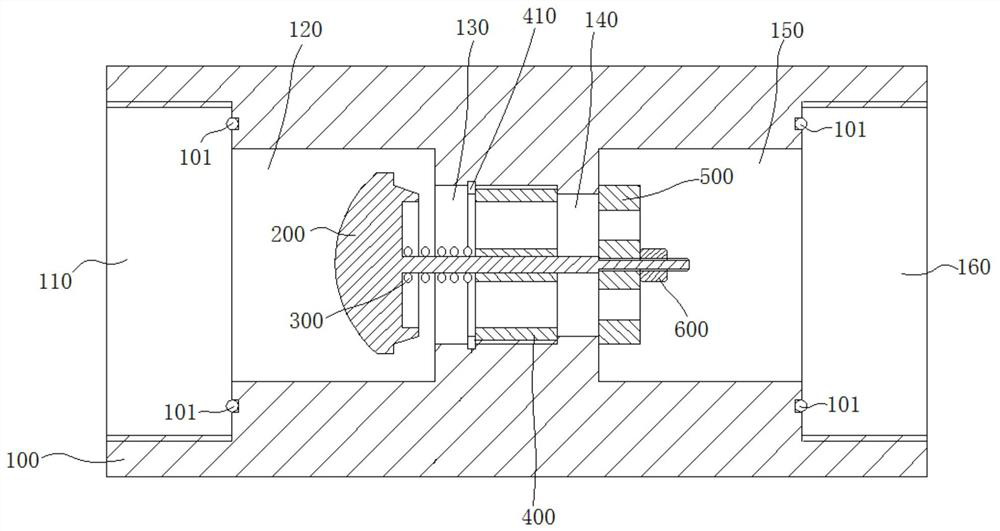

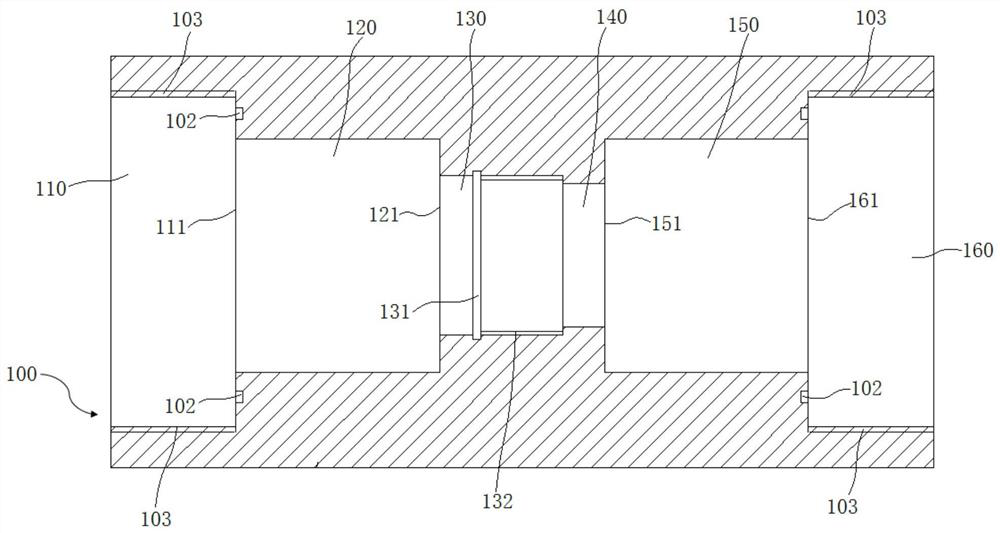

[0041] A common application scenario in the field of fluid control is that in the hydraulic vertical lifting system, the hydraulic cylinder drives the moving weight to move up and down, and the speed of rising and falling is regulated by the flow control system. Once the hydraulic control system fails, the weight will accelerate vertically out of control In the event of a fall, the oil circuit should be closed in time through the one-way valve to achieve a safe speed limit. Therefore, there is a need for a speed control check valve. The fluid can make the fluid flow smoothly in the forward and reverse directions within a certain flow rate range. The reverse shutdown of the road. Using the speed control check valve of this embodiment can meet the requirements in the above application scenarios. Specifically, such as Figure 1-Figure 8 As shown, a speed control check valve in this embodiment includes a valve body 100 and a speed control spool assembly. The two ends of the valv...

Embodiment 2

[0051] A kind of speed control check valve of this embodiment, the basic structure is consistent with embodiment 1, further, as Figure 5 As shown, the diameter of the outer circle of the outer edge of the throttle hole 502 in this embodiment is d, and the outer diameter d is smaller than the diameter of the flow guide cavity 140 , and the diameter of the flow guide cavity 140 is smaller than the diameter of the throttle orifice 500 . The sum of the areas of all the orifices 502 on the orifice plate 500 is less than half of the area of the guide cavity 140 .

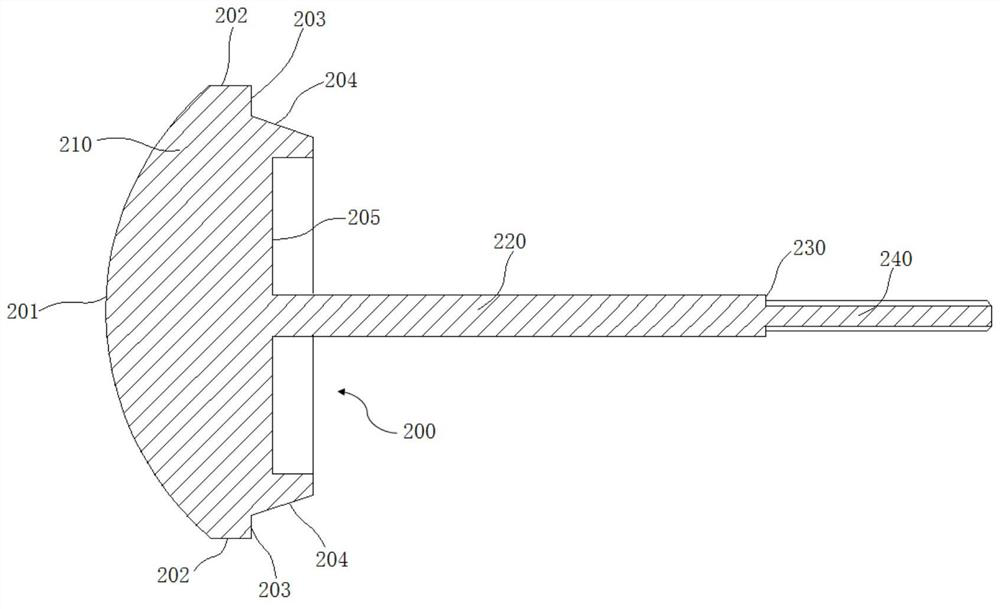

[0052] Such as image 3 As shown, in this embodiment, the end surface of the valve disc 210 away from the valve rod side is the valve disc pressure surface 201. When the fluid flows in the reverse direction, the fluid pressure acts on the valve disc pressure surface 201. When the reverse flow When the fluid velocity exceeds a certain threshold, the control disc 210 compresses the compression spring 300 to the right un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com