High-voltage pulse compound hydraulic fracturing thermal storage method for hot-dry rock

A technology of high-pressure pulse and hydraulic fracturing, which is applied to heat storage equipment, earthwork drilling, indirect heat exchangers, etc., can solve the problems of small artificial heat storage range, expand the range of heat exchange, shorten the operation time, and apply strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The heat storage method of hot dry rock high-pressure pulse composite hydraulic fracturing provided in this embodiment is characterized in that it includes the following steps;

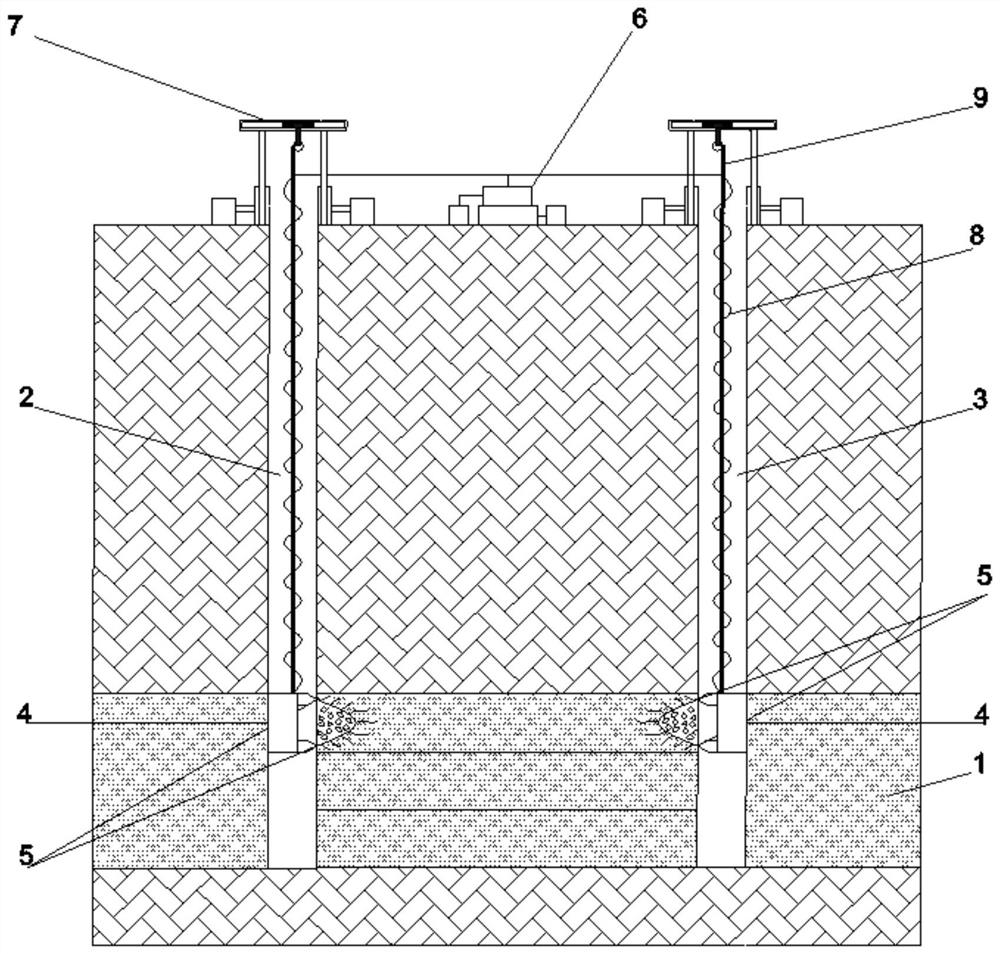

[0043] S1. Determine the depth and range of the hot dry rock reservoir 1 and determine the well group layout plan according to the depth and range of the hot dry rock reservoir 1. Depth and extent of hot rock reservoirs1.

[0044] S2. Construction is carried out on the water injection well 2 and the water production well 3. When the water injection well 2 and the water production well 3 reach the hot dry rock reservoir 1, the drilling is stopped.

[0045] In the process of practical application, the distance between the water injection well 2 and the water production well 3 is 100-1000m.

[0046] S3. Place the high-voltage pulse device 6 on the ground surface, and place the two sets of electrode assemblies 5 electrically connected to the high-voltage pulse device 6 in the water injection well ...

Embodiment 2

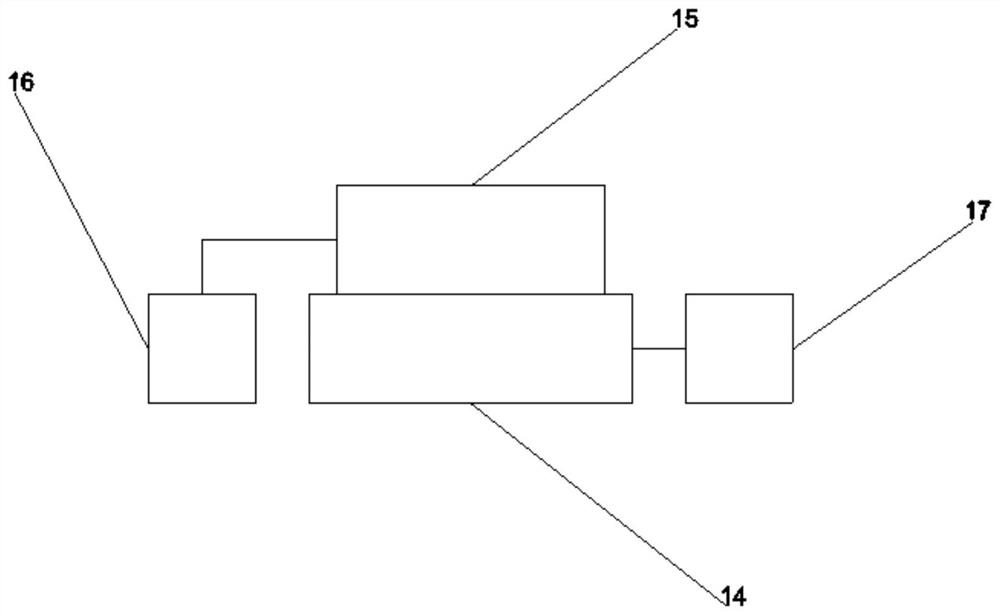

[0059] This embodiment provides the hot dry rock high-pressure pulse composite hydraulic fracturing artificial heat storage system used in the first implementation. The system includes a high-voltage pulse device 6 , two sets of electrode assemblies 5 and two sets of adjustment brackets 7 . Among them, the high-voltage pulse device 6 is placed on the ground surface, two sets of electrode assemblies 5 are electrically connected with the high-voltage pulse device 6, two sets of adjustment brackets 7 are respectively aligned with the wellheads of the pre-constructed water injection well 2 and water production well 3, and the two sets of adjustment brackets 7 are respectively connected with two groups of electrode assemblies 5, which are lowered into the water injection well 2 and the water production well 3 respectively.

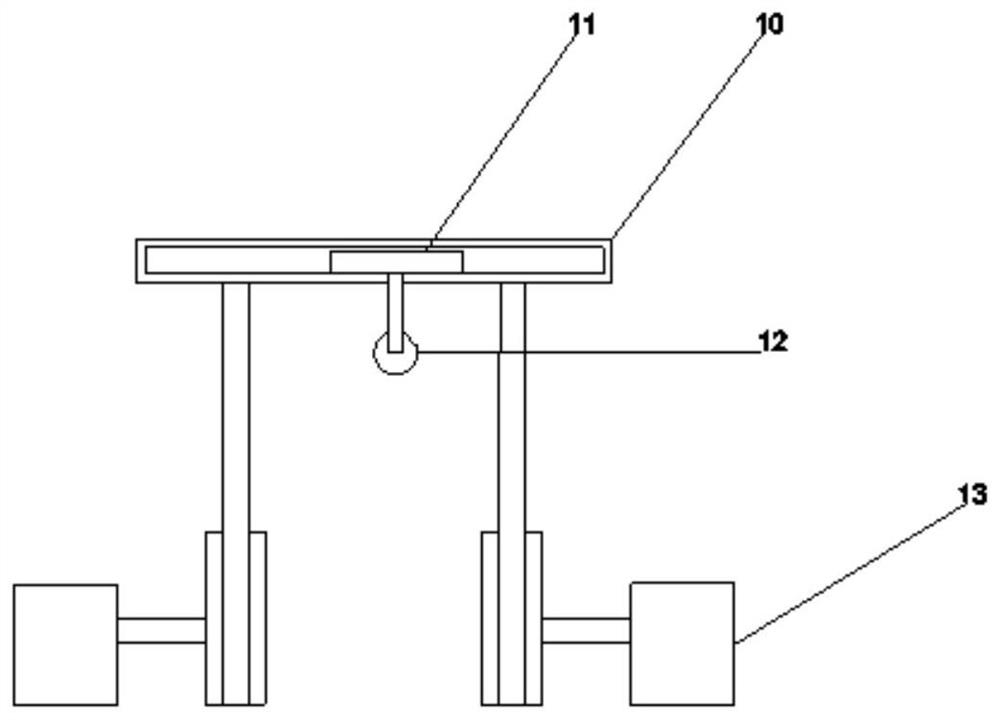

[0060] In this embodiment, the adjustment assembly includes an adjustment bracket 7 , a moving slider 11 and a pulley 12 . Adjusting support 7 comprises vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com