Evaluation method for material selection of abradable sealing coating system from the perspective of corrosion protection

A technology for sealing coating and corrosion protection, applied in the fields of weather resistance/light resistance/corrosion resistance, analytical materials, sustainable transportation, etc. Effect

Active Publication Date: 2022-05-31

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide an evaluation method for the material selection of the abradable seal coating system from the perspective of corrosion protection, aiming to solve the corrosion failure of the coating system caused by "big cathode and small anode" in interlayer galvanic corrosion by guiding material selection Acceleration problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0041] (102) Using a scanning electron microscope, the pore shapes of different porous coatings were observed in secondary electron mode.

[0042] In step 2, the total porosity P (%) and the most probable pore diameter d (cm) of the porous surface layer are obtained through the porosity test.

[0047] V×P=n×π×(d / 2)

[0050] S

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

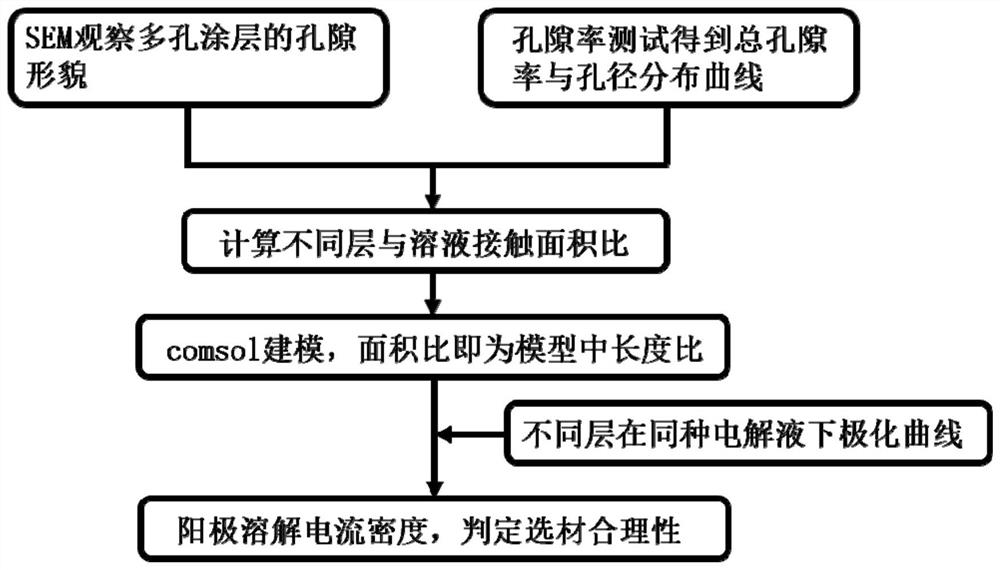

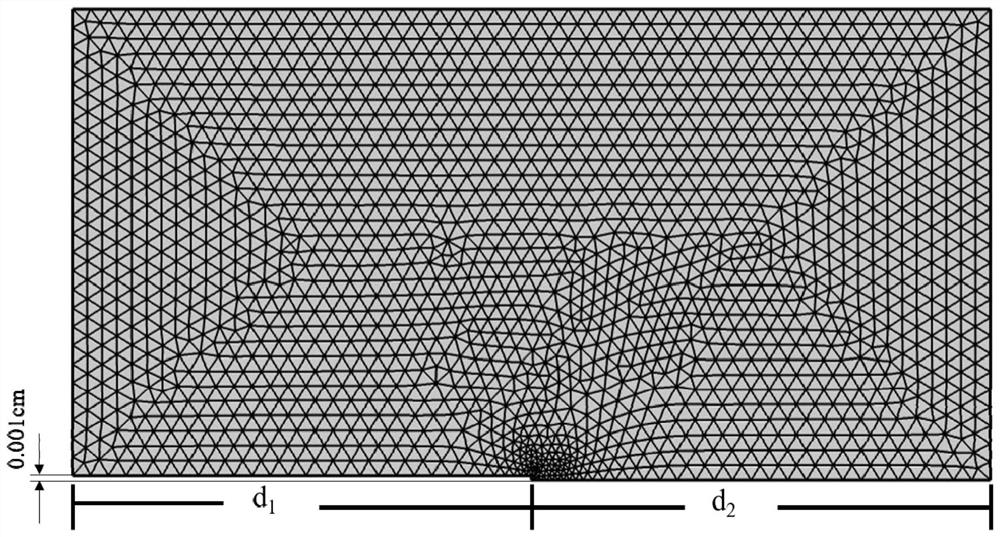

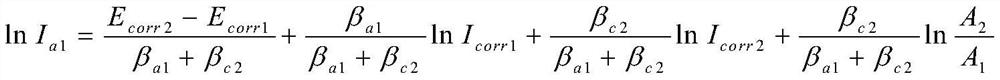

The invention belongs to the field of corrosion and protection research, and specifically relates to an evaluation method for material selection of an abradable sealing coating system from the perspective of corrosion protection. Step 1, analyze the shape of the pores in the porous surface through an electron scanning microscope; step 2, obtain the total porosity and the most probable pore diameter of the porous surface through the porosity test; step 3, according to the results of steps 1 and 2, calculate The ratio of the contact area of each layer to the corrosion solution, using the finite element analysis software to model the local galvanic corrosion in the coating system; step 4, test the polarization curve of each layer in the system, and bring the results into the model as Boundary conditions, culminating in the dissolution current of the metal layer acting as the anode. The present invention uses finite element analysis to model the galvanic corrosion between coatings, and sets boundary conditions through electrochemical test results, and obtains the anode dissolution current in the coating system through simulation calculation, so as to control the coating system The rationality of material selection is evaluated.

Description

Evaluation method for material selection of abradable sealing coating systems from the perspective of corrosion protection technical field The invention belongs to the corrosion and protection research field of multi-layer coating system, be specially a kind of from corrosion protection angle needle Evaluation method for the selection of materials for abradable seal coating systems. Background technique [0002] The abradable seal coating system is a common porous multi-layer coating system, wherein the surface layer of the coating system is due to its Due to the requirements of service performance and there are a lot of pores inside, the joining layer is added to the system to provide bonding force for the entire coating system. It has a wide range of applications in many fields. For example: in the field of gas turbine engines, the application of abradable seal coatings On the premise of protecting the blades from damage, the air path can be sealed to improve effici...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N17/02G01N15/08

CPCG01N17/02G01N15/0886G01N15/0893Y02T50/60

Inventor 李瑛倪雨朦

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com