Maintenance-free efficient energy-saving dry-type electric furnace transformer

An electric furnace transformer, high-efficiency and energy-saving technology, applied in the field of transformers, can solve the problems of reduced power quality and safety, large load loss, and high operating noise, etc., achieves strong resistance to sudden short-circuits, reduces transformer costs, and improves heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

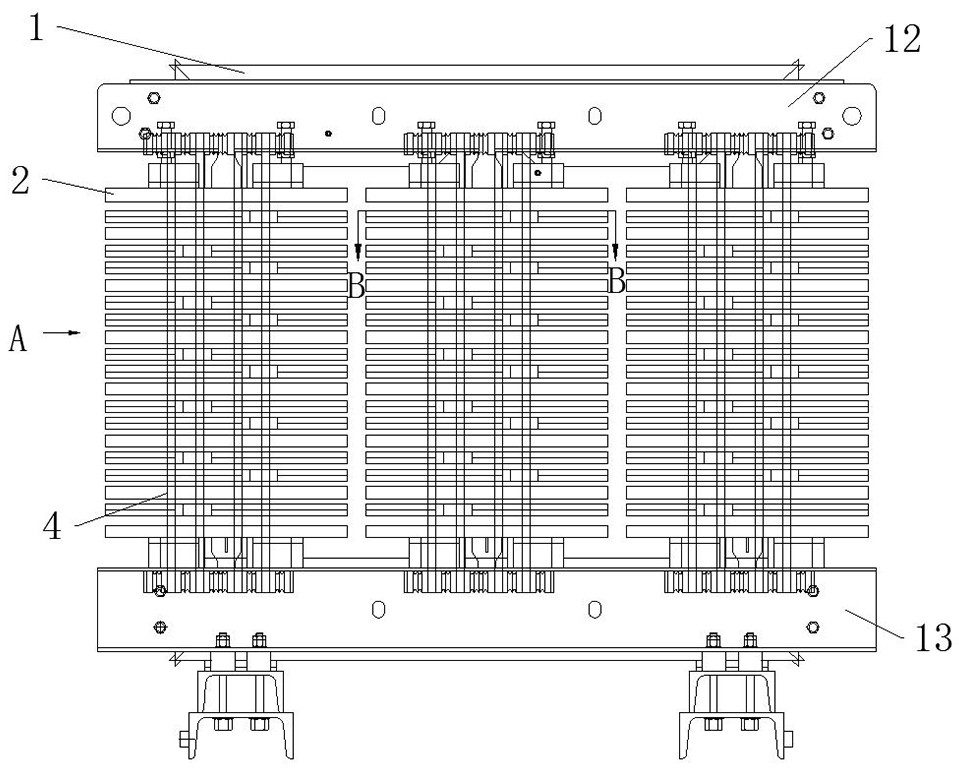

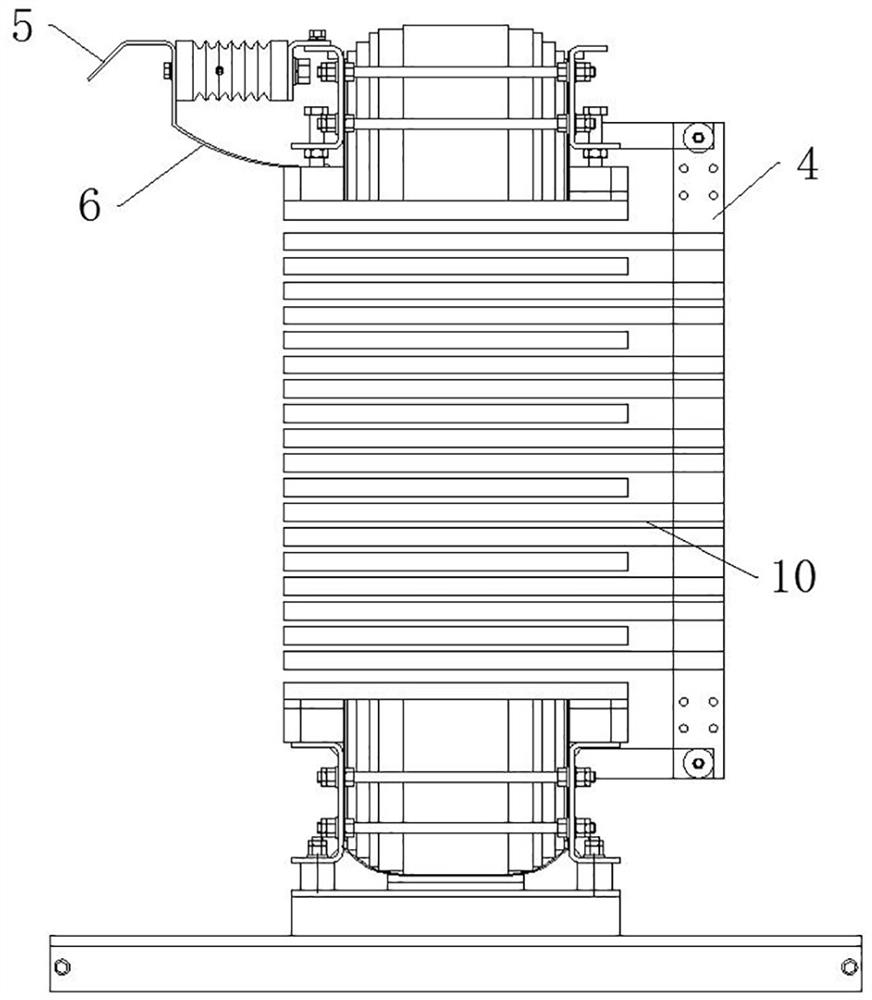

[0021] refer to figure 1 , figure 2 and image 3 , a maintenance-free, high-efficiency and energy-saving dry-type electric furnace transformer, comprising an upper base 12 and a lower base 13, three sets of power transformation cores are arranged between the upper base 12 and the lower base 13, and the three sets of power transformation cores are sequentially along the length direction of the upper base 12 arranged.

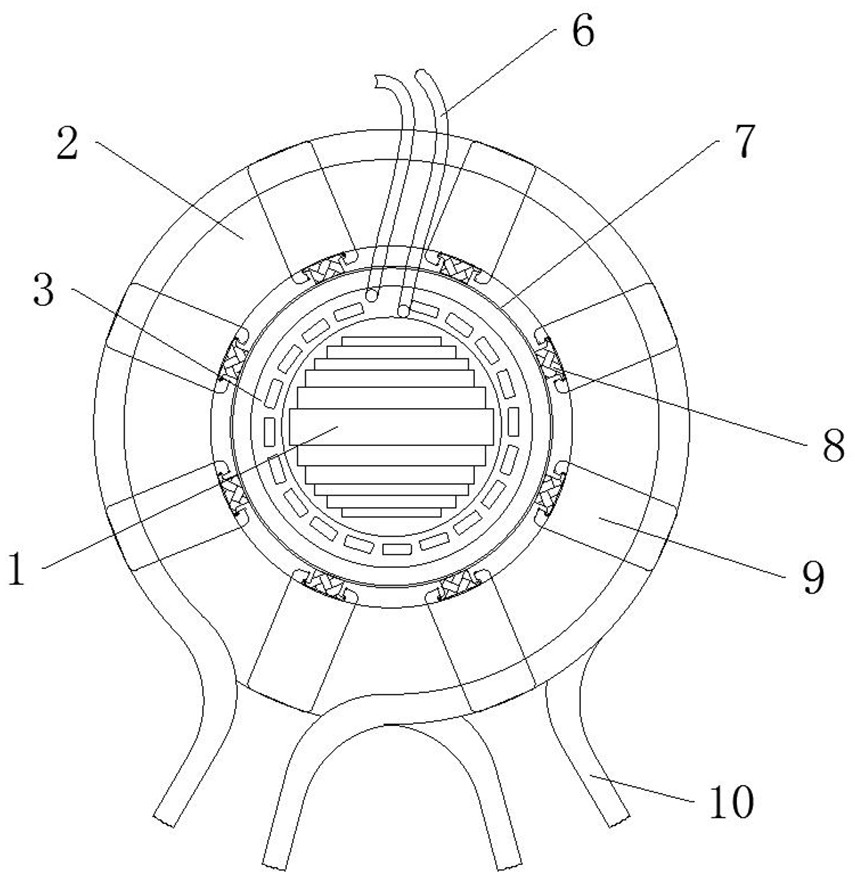

[0022] The power transformation core includes a transformer core 1 , a low voltage coil 2 and a high voltage coil 3 . The transformer core 1 is installed between the upper base 12 and the lower base 13, the low-voltage coil 2 and the high-voltage coil 3 are sleeved on the transformer core 1, and the three are arranged coaxially. The structure of the low-voltage coil 2 is set as an external double pie structure, and the low-voltage coil 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com