A contact-type over-the-wire motor conversion and cancellation assembly and an electrical signal transmission method

A contact and assembly technology, which is applied in the direction of rotating collectors, connections, circuits, etc., can solve the problems of excessive pressure difference and sealing reliability without considering the conversion and offset assembly, affecting the service life of the motor passing the line, etc., to achieve internal and external The effect of consistent pressure and ensuring sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

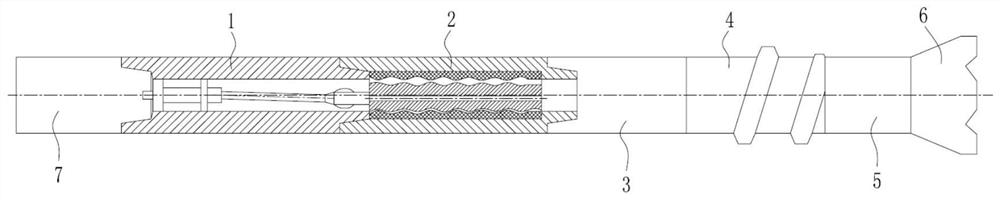

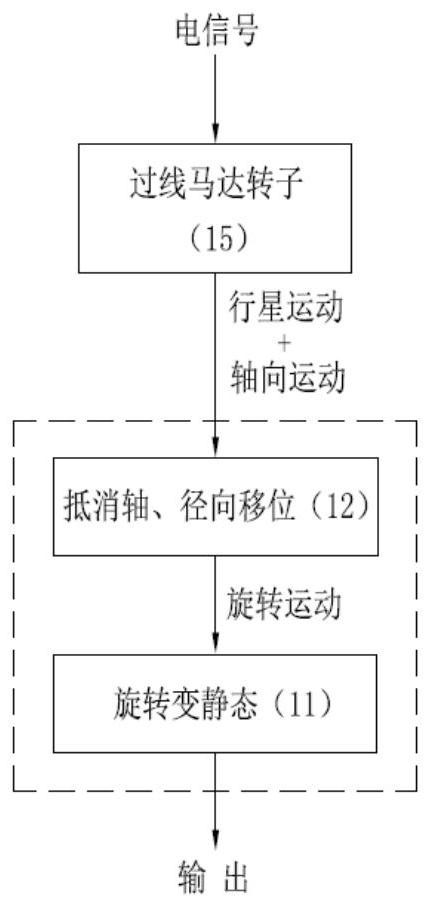

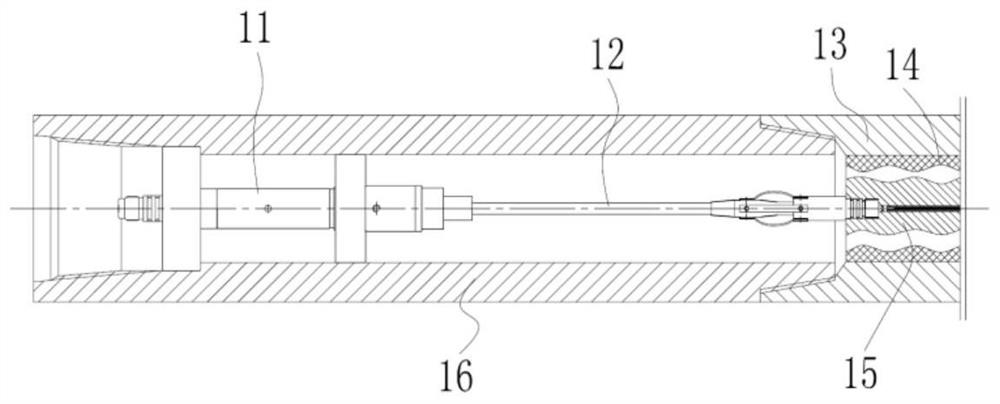

[0047] like Figure 1-5 As shown, a wire-passing motor drilling tool of this embodiment is shown. Including the conversion offset assembly 1 connected to the stator and rotor power joint assembly 2;

[0048] Wherein, the conversion and cancellation assembly 1 includes: a cancellation shaft and a radial displacement device 12, located on the axis of the conversion and cancellation assembly 1, one end of which is connected to the motor rotor 15 of the stator and rotor power joint assembly 2, and the other One end is connected to the rotary variable static output device 11;

[0049] The offset shaft and radial displacement device 12 include:

[0050] The limit protection sleeve 101 is connected to the motor rotor 15, and a freely retractable elastic sealing cable 102 is arranged in it;

[0051]The displacement support shaft 104, the two ends of which are electrically connected to the conductor in the flexible metal tube 105 and the elastic sealing cable 102 respectively;

[0...

Embodiment 2

[0068] see Figure 6-7 , this embodiment provides a contact-type wire-crossing motor conversion and cancellation assembly and an electrical signal transmission method. It uses mutual contact to achieve electrical signal conduction and transfers the electrical signal rotating along the fixed axis to the fixed output end.

[0069] In view of the above problems, the contact-type over-the-wire motor conversion and offset assembly provided in this embodiment includes:

[0070] The positioning mandrel 201 is arranged along the axis of the conversion and cancellation assembly 1 through a sliding bearing 202, and one end thereof is provided with a first contact conductive structure, and the first contact conductive structure is electrically connected to the conductor passing through the motor rotor 15;

[0071] The sealing sheath 210 is provided with a second contact conductive structure in electrical contact with the first contact conductive structure, and one end of the second cont...

Embodiment 3

[0091] like Figure 8 As shown, this embodiment provides a separate wire-passing motor conversion and cancellation assembly and an electrical signal transmission method.

[0092] A separate wire-passing motor conversion and cancellation assembly of this embodiment includes:

[0093] The positioning mandrel 201 is arranged along the axis of the conversion and cancellation assembly 1 through a sliding bearing 202, and one end thereof is connected to a conductive transmission mandrel 217 through an insulating sleeve 216, and a conductor is arranged therein to electrically connect the transmission mandrel 217 and the conductors passing through the motor rotor 15;

[0094] The conduction housing 219 is electrically connected to the signal pairing connector 215 and forms a conductive cavity with the transmission mandrel 217 , and the conductive cavity is filled with conductive liquid.

[0095] As an implementation manner of this embodiment, a positioning bearing 218 is disposed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com