Auxiliary machine for czochralski silicon single crystal furnace thermal field disassembling and cleaning

A technology of single crystal furnace and Czochralski silicon, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low disassembly efficiency and achieve the effect of improving disassembly efficiency, reducing pollution degree and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

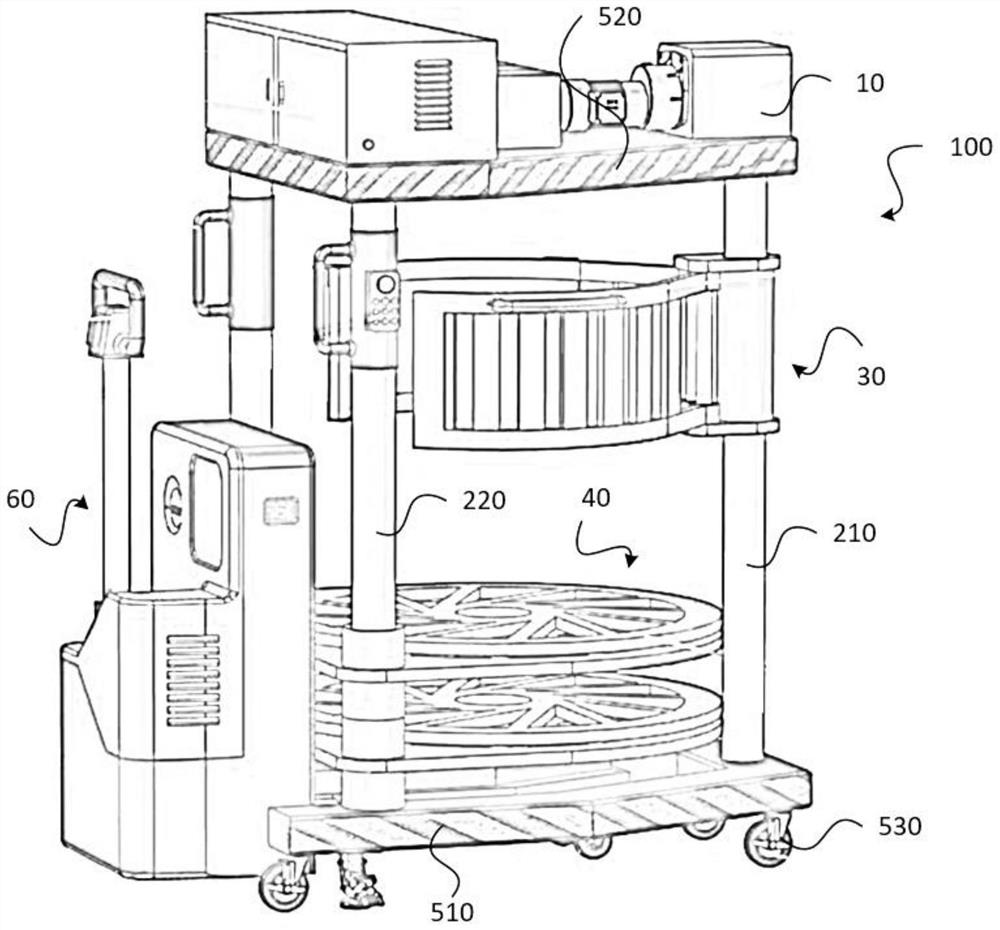

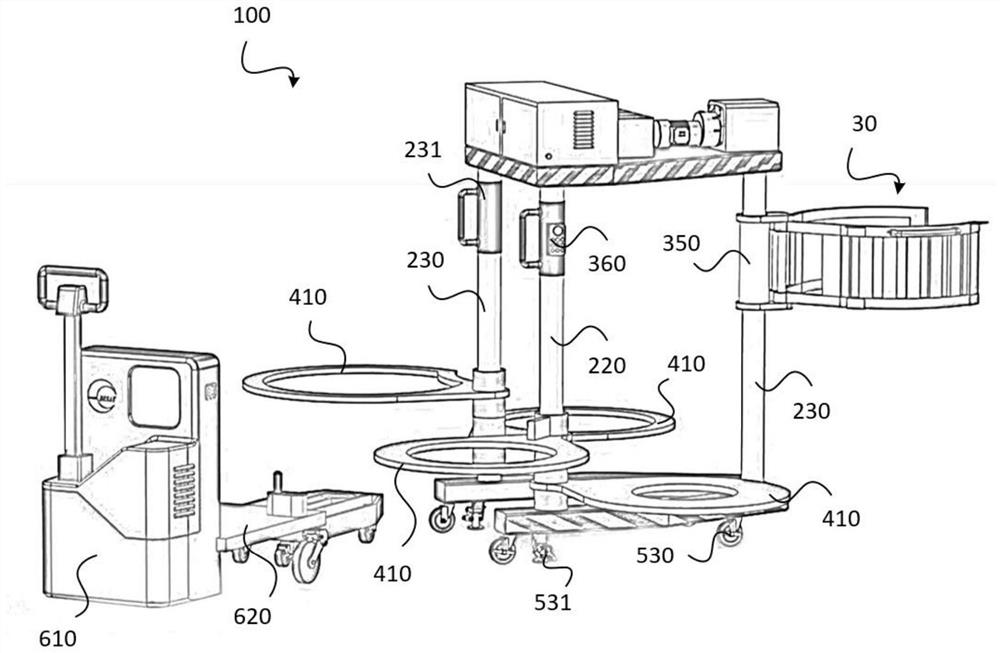

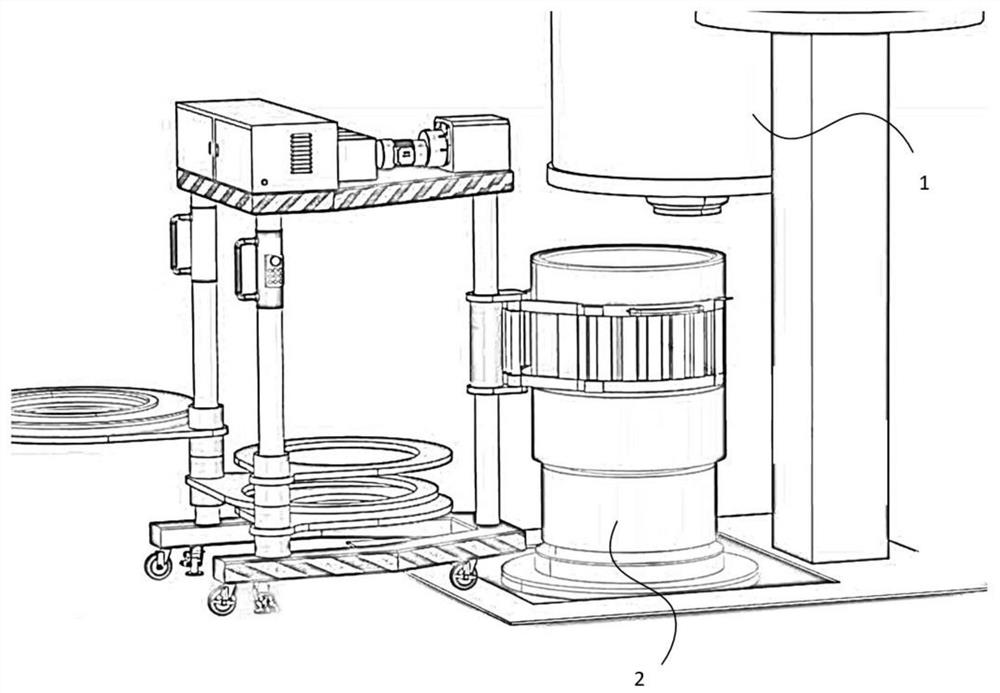

[0038] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0039] In the production process of the Czochralski single crystal furnace, the dismantling of the furnace is the last step of all processes. Generally, it takes a long time to cool down before dismantling the furnace. There are many tools needed in the process of dismantling the furnace, and the dismantling of the furnace requires The site is relatively large, so that the efficiency of the entire dismantling process is low, and the surrounding environmental pollution is relatively large. For this reason, the auxiliary machine for dismantling the thermal field of the Czochralski silicon single crystal furnace provided by the present invention is set for the devices that need to be disassembled in the single crystal furnace, so as to dismantle the single crystal furnace mechanically and improve the disassembly efficiency of the single cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com