Flow pulse counter and application thereof

A pulse counter and flow technology, which is used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

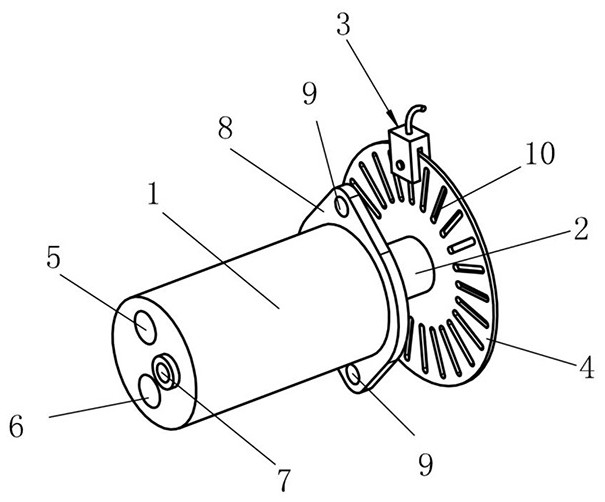

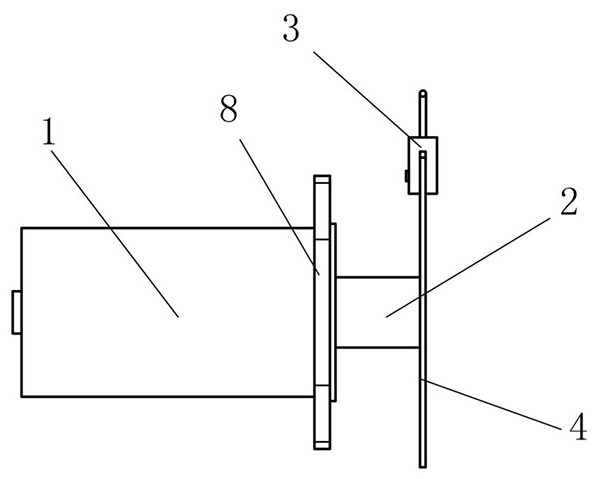

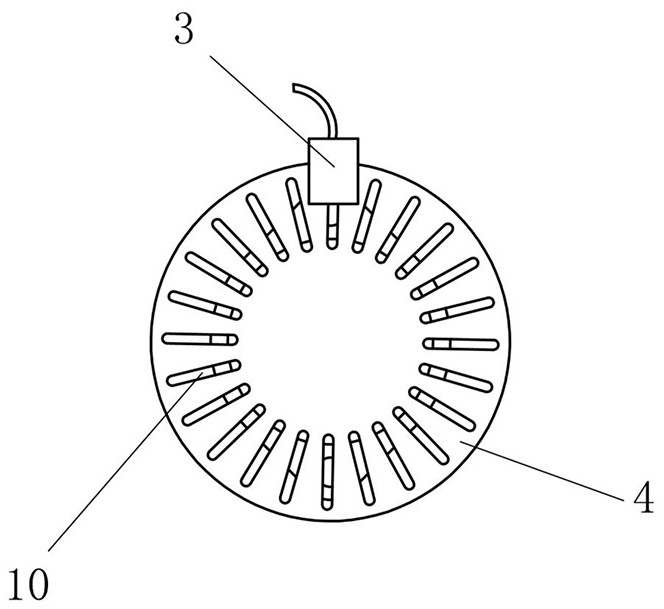

[0031] Such as figure 1 As shown, an application of a flow pulse counter, the oil inlet pipe 5 of the flow pulse counter is externally connected to the reversing valve of the multi-face milling head of the CNC machine tool, and the oil return pipe 6 of the flow pulse counter is externally connected to the cutting tool of the multi-face milling head of the CNC machine tool cylinder, when a certain flow of oil enters the knife piston through the hydraulic motor, the hydraulic motor 1 drives the code disc 5 to rotate, and the photoelectric switch 3 detects the number of revolutions of the code disc 5 to determine the volume of the oil flowing into the hydraulic motor 1. In order to judge whether the multi-faceted milling head of the CNC machine tool is in place, this test method can use the flow pulse counter to judge whether the multi-faceted milling head of the CNC machine tool is in place, so that no pressure relay signal is needed. This detection method is accurate and reliabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com