Integrated environment simulation test device and method

An environmental simulation test and integrated technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, space navigation equipment, etc., can solve the problems of wasting test time and increasing test costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

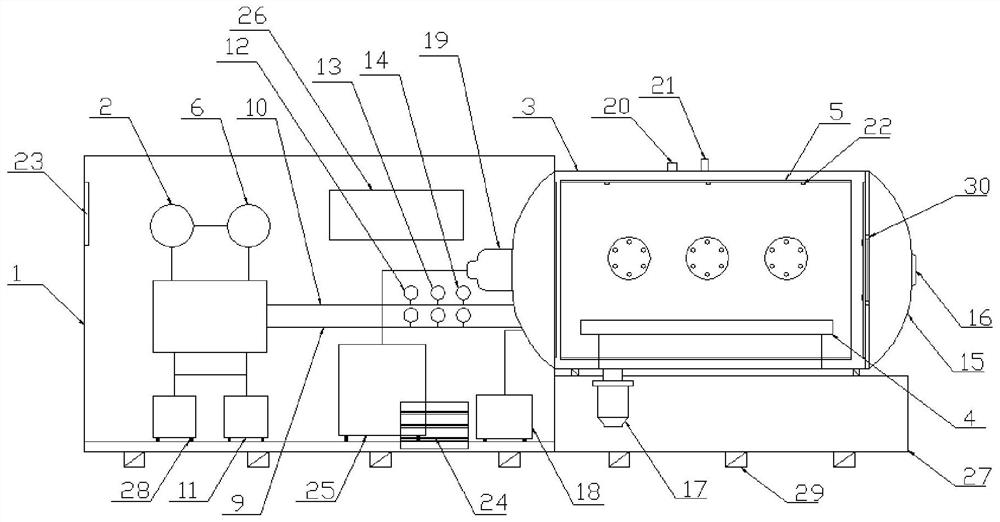

[0030] Please refer to figure 1 and figure 2 The schematic structural diagram of the first embodiment of an integrated environmental simulation test device provided by the present application includes: a box body 1 and a temperature adjustment mechanism 2 arranged inside the box body 1;

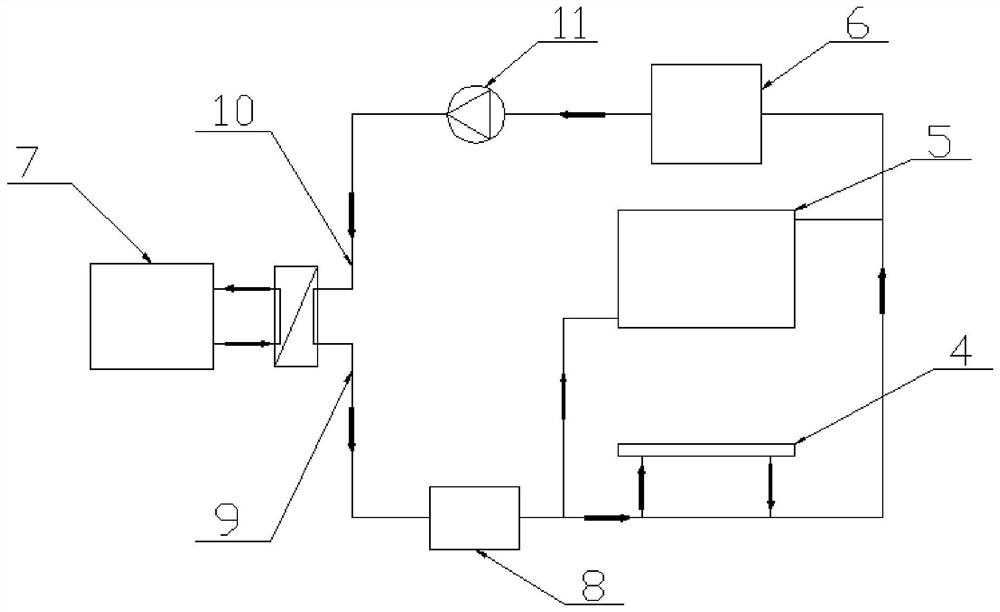

[0031] The box body 1 is connected with a vacuum tank 3 arranged horizontally, and a cold plate 4 is horizontally arranged in the vacuum tank 3 for placing test samples; the inner wall of the vacuum tank 3 is provided with a heat sink 5;

[0032] The temperature adjustment mechanism 2 includes: a circulating working fluid storage part 6, a cooling part 7 and a heating part 8; the output end of the cooling part 7 communicates with the input end of the heating part 8 through a heat exchange pipeline 9; The two output ends of the heating part 8 communicate with the heat sink 5 and the input ends of the cold plate 4 respectively through the heat exchange pipeline inlet 9, and the output ends of...

Embodiment 2

[0063] A method for an integrated environmental simulation test device as described in Embodiment 1, characterized in that it comprises the following steps:

[0064] Check the operation status of each component and the connecting cable, if the operation is normal, install the test sample on the cold plate 4 correctly, and close the cover 15;

[0065] Using the molecular pump 17, the dry pump 18 and the cryopump 19 to vacuumize the vacuum tank 3;

[0066] When the vacuum reaches the test requirements, start the temperature adjustment mechanism 2 to adjust the temperature of the test sample;

[0067] The measurement and control platform 26 is used to control the environment required by the test, and to record and output the test data.

[0068] In this embodiment, all operating states of circulating water, components, pipelines and valves are checked before the test;

[0069] If the operation is not normal, carry out maintenance;

[0070] If the operation is normal, the test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com