Power plant sewage treatment method

A treatment method and technology for power plants, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of high water treatment costs, environmental pollution, and complicated operations. , to achieve the effects of good water conductivity and desalination stability, extended cleaning cycle and short recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

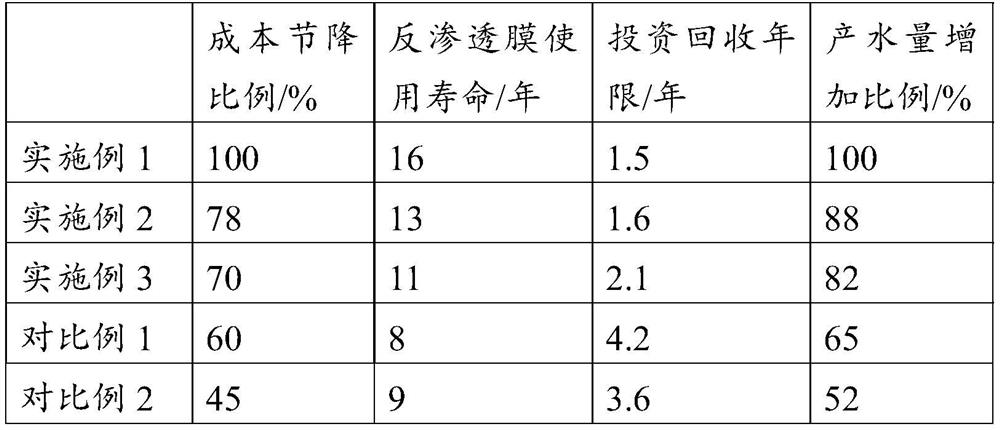

Examples

Embodiment 1

[0020] Adopt method of the present invention to total hardness be 2000mg / L (as CaCO 3 Purification of power plant sewage: first, the power plant sewage is subjected to organic matter removal, heavy metal removal, softening treatment and filtration pretreatment, and then the pretreated power plant sewage enters the reverse osmosis device for reverse osmosis treatment, and obtains first serum and concentrate;

[0021] Let the first clear liquid enter the membrane crystallization device, perform the membrane crystallization treatment at 5-40°C, obtain solid salt crystal particles on one side of the membrane, and obtain purified water on the other side;

[0022] The concentrated solution enters the settling tank for the settling treatment to obtain the second clear liquid and mud, the mud is drawn out of the system, and the second clear liquid is mixed with the first clear liquid and then enters the membrane A crystallization device performs the film crystallization process;

[...

Embodiment 2

[0025] The method of Embodiment 1 is used to treat the sewage of the power plant, the only difference is that the power of the electromagnetic antiscaling coil is 100W.

Embodiment 3

[0027] Adopt the method for embodiment 1 to process power plant sewage, difference is only: the total hardness of described power plant sewage is 5000mg / L (as CaCO 3 count).

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com