Trans-butadiene-isoprene rubber/filling oil composite material and preparation method thereof

A technology of butyl pentylene rubber and composite materials, which is applied in the field of rubber and can solve the problems of less research on the synthesis and modification of trans butyl pentylene rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a kind of preparation method of trans-butadiene rubber / extender oil composite material as described above, comprises the following steps:

[0038] Mix trans-butadiene rubber, extender oil and anti-aging agent to carry out oil-extender modification to obtain trans-butadiene rubber / extender oil composite material.

[0039] According to the formula of the first trans-butadiene rubber / extender oil composite material or the second trans-butadiene rubber / extender oil composite material above, mix trans-butadiene rubber, extender oil and anti-aging agent to carry out oil-extended modification The oil-filled modified device is preferably a twin-screw extruder, a single-screw extruder, an internal mixer, an intermeshing screw extruder / reactor, a self-cleaning reactor, a horizontal reactor, and a tank reaction reactor or rake reactor.

[0040] In the present invention, the temperature of the oil-extended modification is preferably 40-90°C, mor...

Embodiment 1

[0044] The molar content of butadiene structural units using trans-butadiene rubber is 35%, the molar content of isoprene structural units is 65%, Mooney viscosity ML 3+4 100℃ for 90. Trans-butadiene rubber: environmentally friendly aromatic oil: anti-aging agent 2,6-di-tert-butyl-4-methylphenol according to the mass ratio of 100:10:1 using internal mixer to prepare trans-butadiene rubber / extender oil composite material , the temperature of the internal mixer is 60° C., the rotating speed is 60 rpm, and the time is 3 minutes. The prepared trans-butadiene rubber / extender oil composite was named OTBIR-1.

Embodiment 2

[0046] The molar content of butadiene structural units using trans-butadiene rubber is 10%, the molar content of isoprene structural units is 90%, Mooney viscosity ML 3+4 100℃ for 120. Trans-butadiene rubber: environmentally friendly aromatic oil: anti-aging agent 2,6-di-tert-butyl-4-methylphenol according to the mass ratio of 100:35:1 using internal mixer to prepare trans-butadiene rubber / extender oil composite material , prepared by a twin-screw extruder with a screw speed of 20 rpm and a time of 6 minutes. The prepared trans-butadiene rubber / extender oil composite was named OTBIR-2.

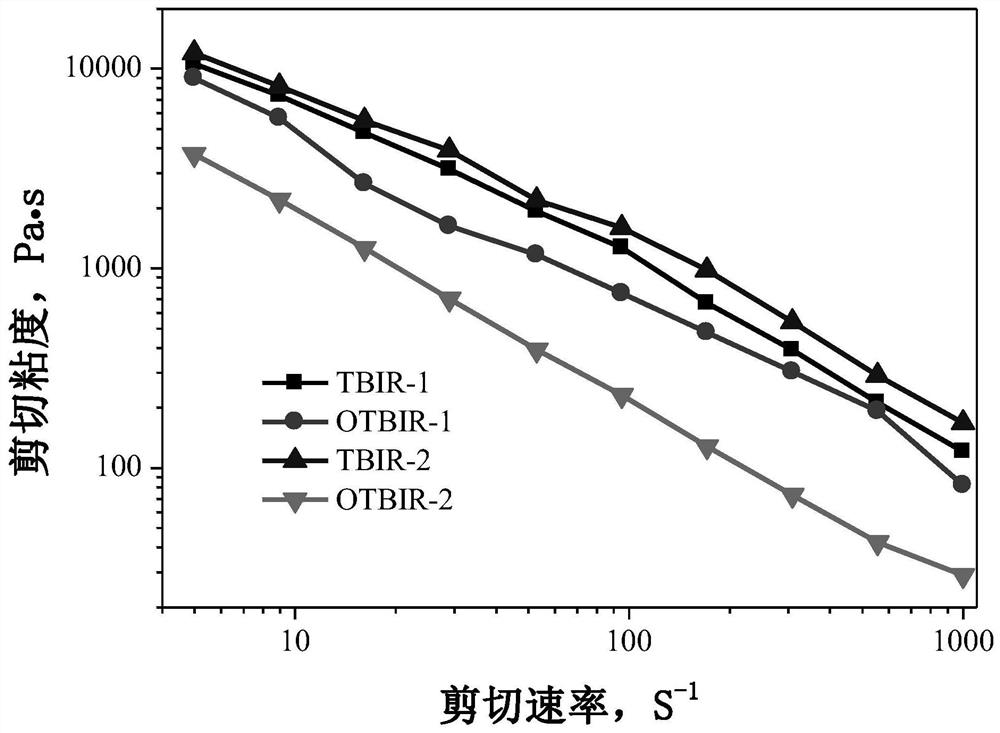

[0047] Capillary rheometer was used to study the processability of trans-butadiene rubber / extender oil composite material, the molar content of butadiene structural unit was 35%, the molar content of isoprene structural unit was 65%, Mooney viscosity ML 3+4 100℃ Be the shear viscosity~shear rate curve of the trans-butadiene rubber (TBIR-1) of 90 and the trans-butadiene rubber / extender oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com