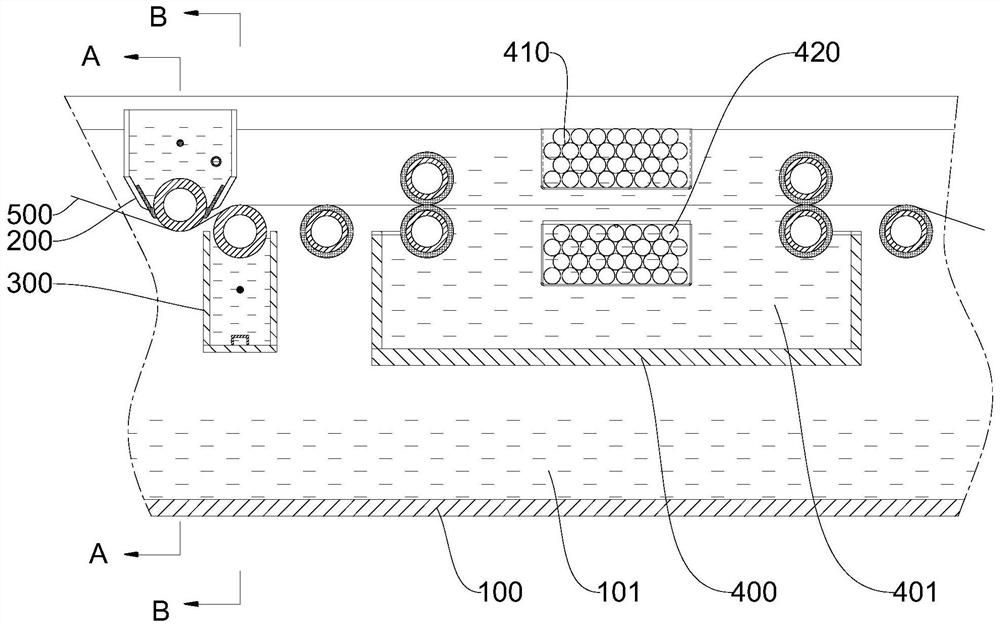

A device and method for preventing copper plating of conductive rollers

A conductive roller and copper plating technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of affecting the effective components of the plating solution, unable to completely remove the residual copper particles, and unable to meet the requirements of non-metallic copper coating, etc., to increase the process The process and device structure are simple, and the effect of avoiding copper residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

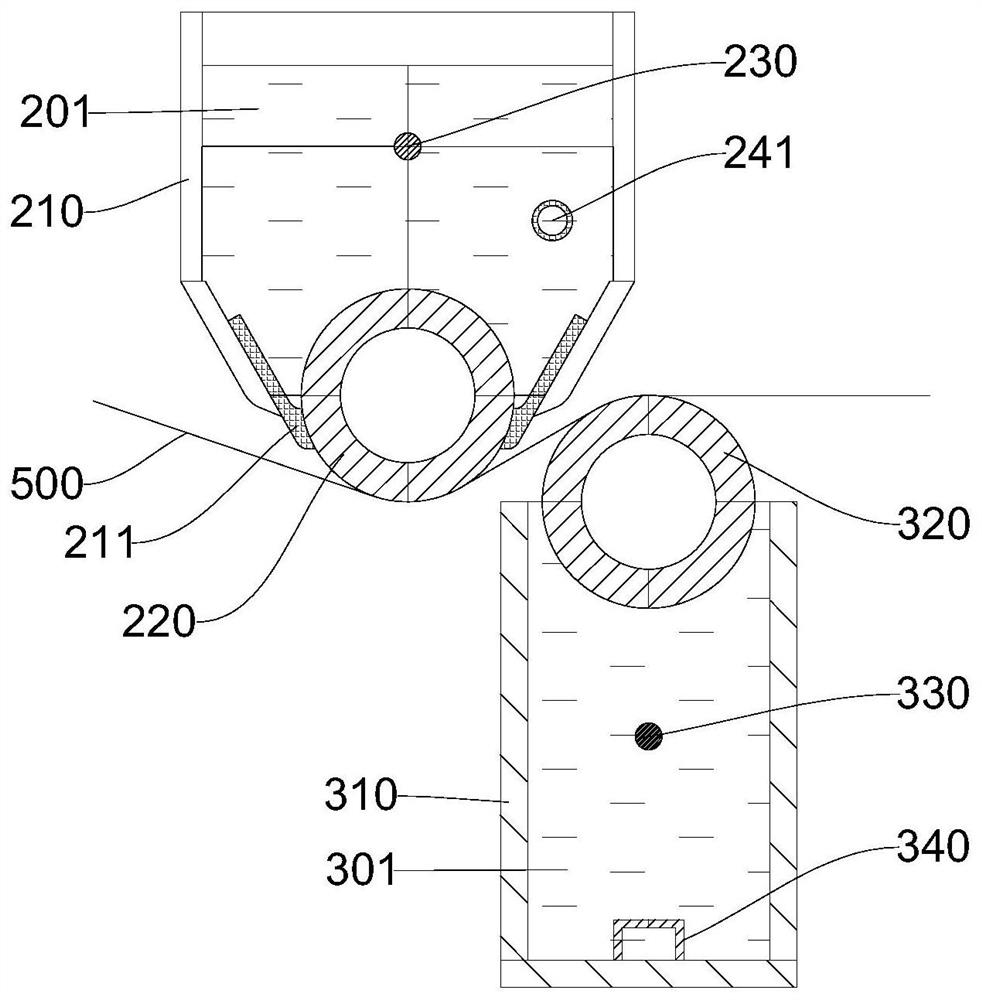

[0045] Preferably, the auxiliary electrode is a copper rod, and a copper rod, a titanium rod, a stainless steel rod, a titanium-clad copper rod, etc. can also be used.

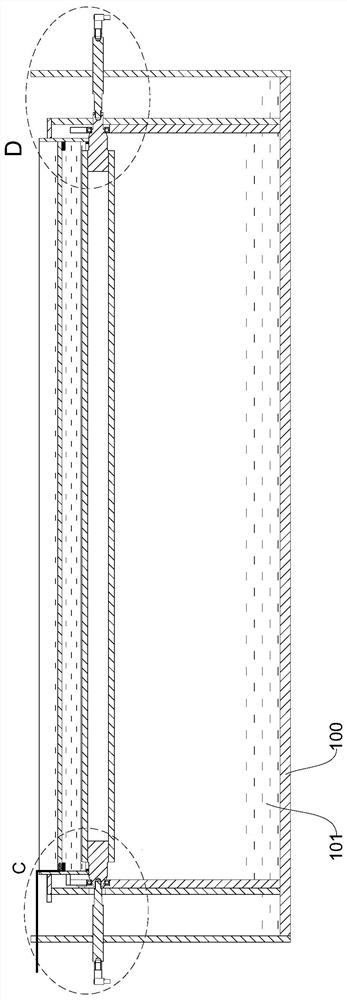

[0049] In order to avoid liquid leakage, the upper conductive roller 220 is sealed with the upper auxiliary groove 200. In this embodiment, the opening is provided with

[0065] The positive output terminal V2+ of the second power supply is connected to the other end of the conductive roller (the upper conductive roller 220 and the lower conductive roller 320),

[0067] Through this circuit connection, it is achieved that the conductive rollers (the upper conductive roller 220 and the lower conductive roller 320) are in cooperation with the electroplating anode

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com