Polymerized product preparation system based on plant fiber mould pressing

A plant fiber and preparation system technology, applied in textiles and papermaking, raw material separation, etc., can solve problems such as low preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

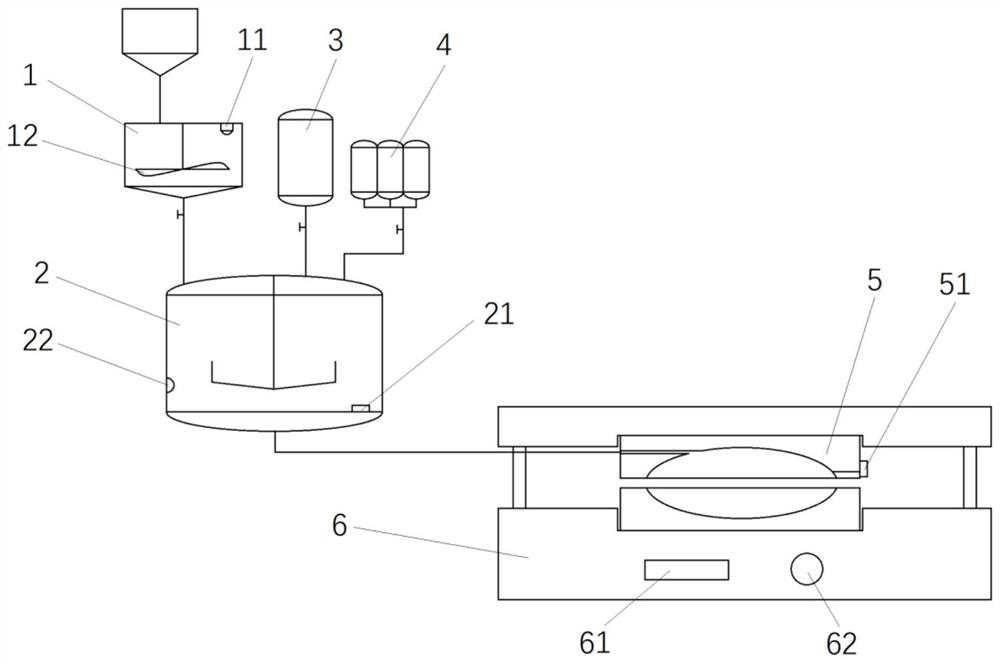

Method used

Image

Examples

preparation example Construction

[0113] Before the preparation of plant fiber molded polymer products, the central control unit judges the use of the product to be prepared and sets the size standard of the crushed plant fiber according to the judgment result:

[0114] When the use of the product to be prepared is S1, the central control unit selects the parameters in the C1 matrix as the size standard of the crushed plant fiber;

[0115] When the use of the product to be prepared is S2, the central control unit selects the parameters in the C2 matrix as the size standard of the crushed plant fiber;

[0116]When the use of the product to be prepared is S3, the central control unit selects the parameters in the C3 matrix as the size standard of the crushed plant fiber;

[0117] When the use of the product to be prepared is S4, the central control unit selects the parameters in the C4 matrix as the size standard of the crushed plant fiber;

[0118] When the central control unit selects the parameters in the Ci...

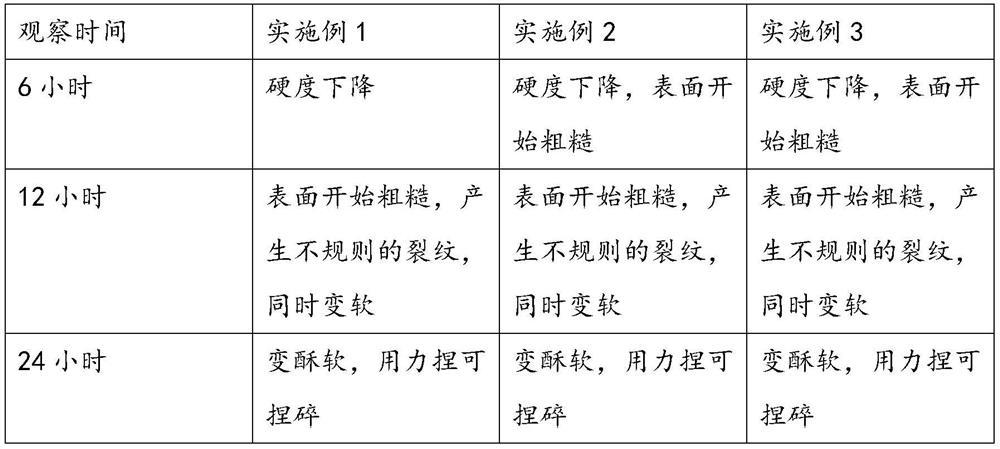

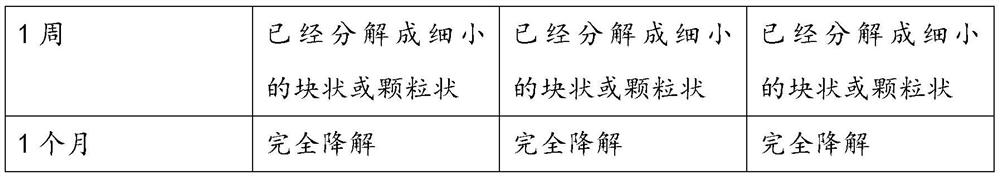

Embodiment 1

[0193] (1) get plant fiber 50kg; Plant fiber products fire-resistant mildew-proof special agent 50kg; Starch 40kg; Boiling water 450kg; Add 450kg of boiling water and stir evenly, then add 40kg of starch and 3kg of release agent and stir until it becomes a paste for later use;

[0194] (2) Molding: Pour the prepared paste into the molding cavity, compress and seal the mold with a hydraulic press, the raw materials are polymerized and puffed in the cavity, and then demolded to obtain the plant fiber molding of various mold shapes Polymer products; wherein, the molding temperature is 275°C, and the molding time varies according to different molded polymer products.

Embodiment 2

[0196] (1) get plant fiber 60kg; Plant fiber products fire-resistant mildew-proof special agent 60kg; Starch 50kg; Boiling water 480kg; Add 480kg of boiling water and stir evenly, then add 50kg of starch and 4kg of release agent and stir until it becomes a paste for later use;

[0197] (2) Molding: Pour the prepared paste into the molding cavity, compress and seal the mold with a hydraulic press, the raw materials are polymerized and puffed in the cavity, and then demolded to obtain the plant fiber molding of various mold shapes Polymer products; wherein, the molding temperature is 280°C, and the molding time varies according to different molded polymer products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com