High-flatness construction method for asphalt pavement

A construction method and asphalt pavement technology, applied in the field of asphalt construction, can solve problems such as slowing down construction progress, low flatness, and difficult measurement work, and achieve the goals of reducing the number of rolling times, increasing the rolling effect, and promoting the rolling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

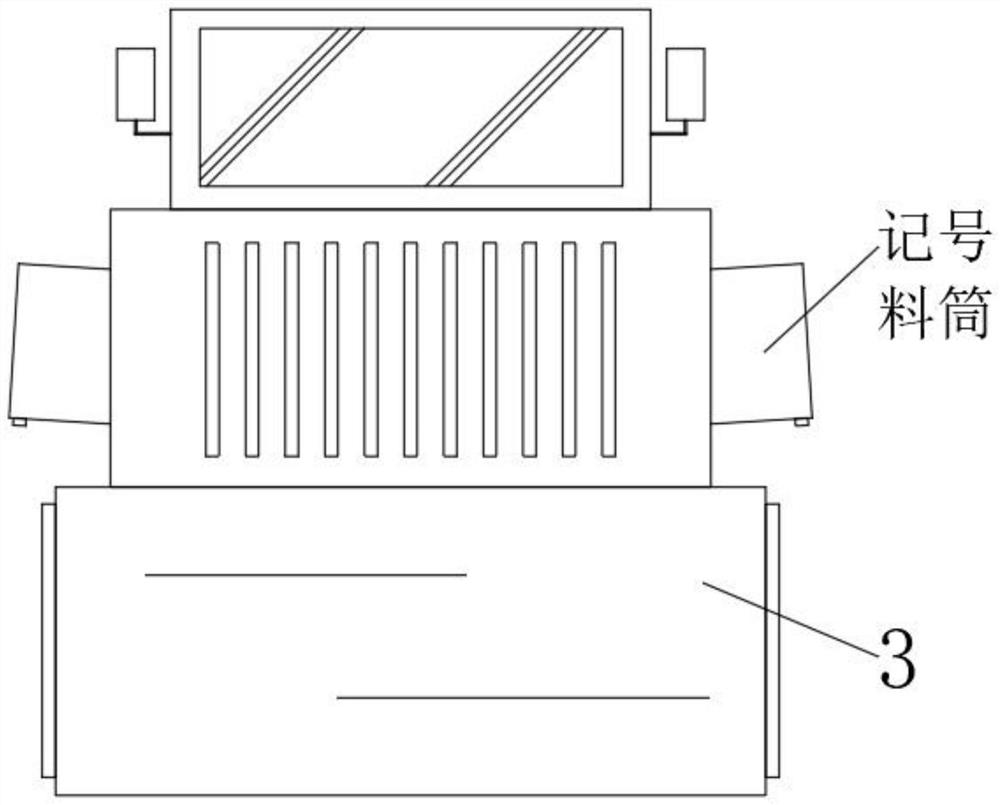

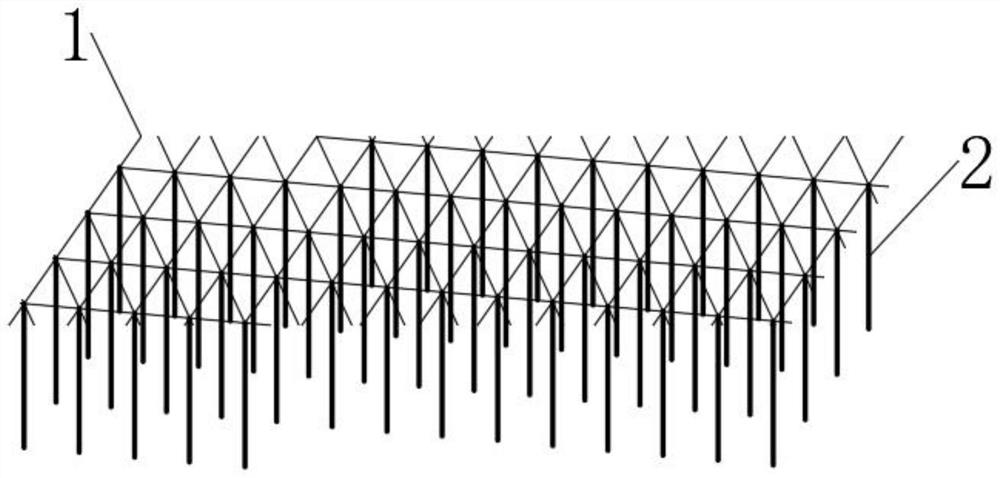

[0043] see figure 1 , a kind of asphalt pavement high smoothness construction method, comprises the following steps:

[0044] S1. Before construction, clean the base to ensure that the base is dry and clean without any loose stones, dust and impurities, and repair the pit defects existing in the base;

[0045] S2. Weigh the raw materials according to the ratio and mix them to prepare the asphalt mixture, and transport it to the construction site and put it into use immediately;

[0046] S3. Pave the asphalt mixture with the paver, and comb the paved asphalt mixture in real time by configuring the combing net behind the paver, and use more than 2 paver to form an echelon combination For paving, the distance between the front and rear paver machines shall not exceed 100m, and the paving speed shall be 3.5m / min;

[0047] S4. Preheat the new hot rolling roller on the road roller to 155°C, and carry out the initial pressure closely following the paver. Both sides of the road roll...

Embodiment 2

[0058] A method for constructing asphalt pavement with high smoothness, comprising the following steps:

[0059] S1. Before construction, clean the base to ensure that the base is dry and clean without any loose stones, dust and impurities, and repair the pit defects existing in the base;

[0060] S2. Weigh the raw materials according to the ratio and mix them to prepare the asphalt mixture, and transport it to the construction site and put it into use immediately;

[0061] S3. Pave the asphalt mixture with the paver, and comb the paved asphalt mixture in real time by configuring the combing net behind the paver, and use more than 2 paver to form an echelon combination For paving, the distance between the front and rear paver machines shall not exceed 100m, and the paving speed shall be 3.5m / min;

[0062] S4. Preheat the new hot rolling roller on the road roller to 160°C, and carry out the initial pressure closely following the paver. Both sides of the road roller for the ini...

Embodiment 3

[0069] A method for constructing asphalt pavement with high smoothness, comprising the following steps:

[0070] S1. Before construction, clean the base to ensure that the base is dry and clean without any loose stones, dust and impurities, and repair the pit defects existing in the base;

[0071] S2. Weigh the raw materials according to the ratio and mix them to prepare the asphalt mixture, and transport it to the construction site and put it into use immediately;

[0072] S3. Pave the asphalt mixture with the paver, and comb the paved asphalt mixture in real time by configuring the combing net behind the paver, and use more than 2 paver to form an echelon combination For paving, the distance between the front and rear paver machines shall not exceed 100m, and the paving speed shall be 3.5m / min;

[0073] S4. Preheat the new hot rolling roller on the road roller to 165°C, and carry out the initial pressure closely following the paver. Both sides of the road roller for the ini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com