A composite flexible support integrated support system for deep foundation pit engineering

A support system and deep foundation pit technology, applied in infrastructure engineering, construction, climate change adaptation, etc., can solve problems such as low construction efficiency and poor support effect, achieve convenient construction, improve self-bearing capacity, and improve firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

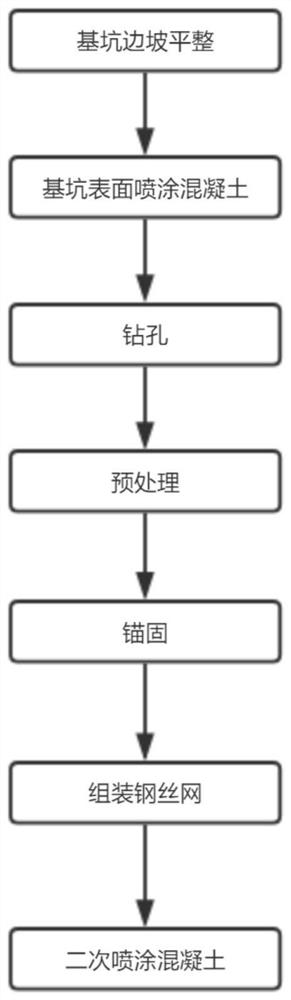

[0037] refer to Figure 1-6 , a composite flexible support integrated support system for building deep foundation pit engineering, comprising the following steps:

[0038] S1. Level the slope of the foundation pit;

[0039] S2. Quickly spray concrete on the slope trimmed in step S1, and seal the foundation pit slope in time;

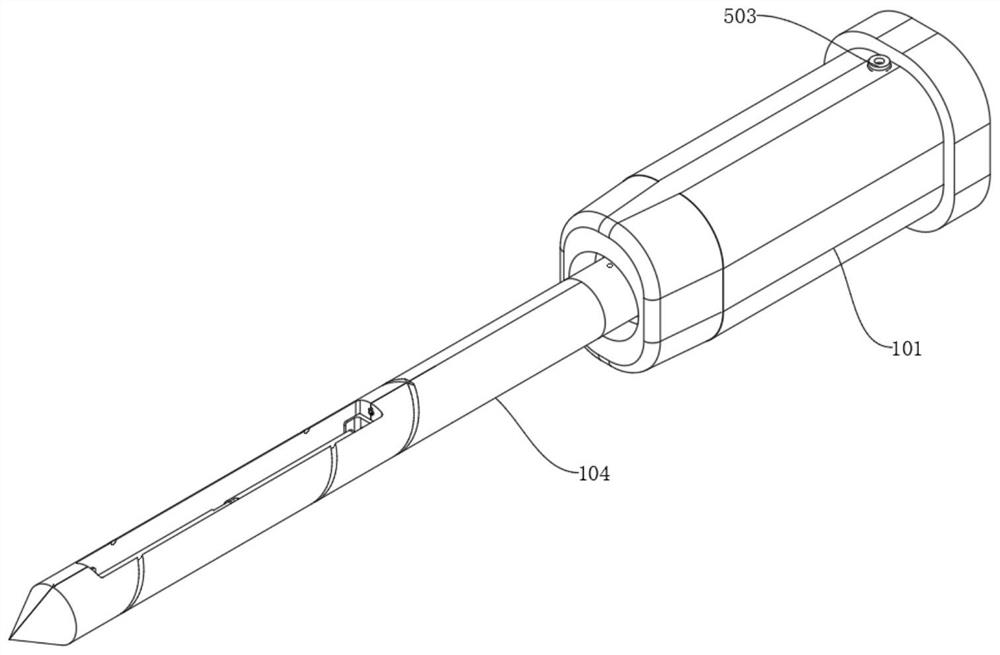

[0040] S3. After the concrete in step S2 is solidified, use a pre-treatment drilling tool to drill the hole according to the support design, and after the drilling is completed, pre-process the inside of the drill hole;

[0041] S4. After the pretreatment is completed, inject cement slurry into the anchor hole and insert the anchor rod;

[0042] S4. Install a prefabricated steel mesh frame on the slope of the foundation pit after the construction of the anchor rod. Two adjacent steel mesh frames are connected to the ends of the anchor rod through connecting components. The bottom of each steel mesh frame frame is reserved for insertion ends. Insert the ...

Embodiment 2

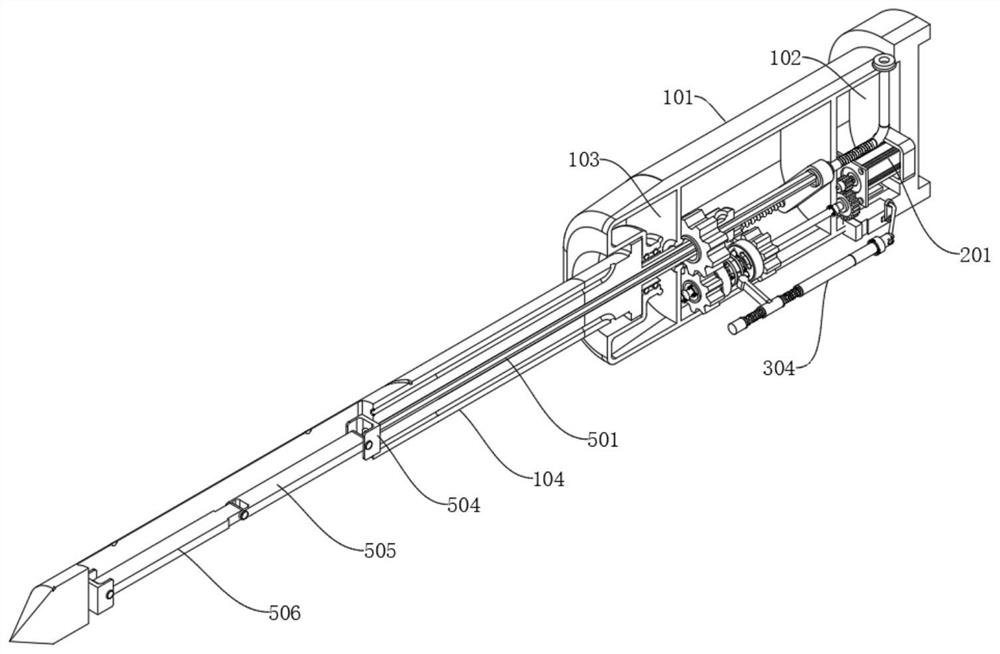

[0048] Embodiment 2: What is different based on Embodiment 1 is;

[0049] The power driving mechanism includes: a servo motor 201, a driving gear 202, a rotating gear 203, a left switching gear 204, a right switching gear 205, a spline shaft 206 and a linkage gear 207. The front end of the main shaft of the servo motor 201 is fixedly connected to the shaft center of the driving gear 202, The lower side of the driving gear 202 is meshed with the upper side of the rotating gear 203, the axis of the rotating gear 203 is fixedly connected to the left side of the spline shaft 206, and the left switching gear 204 and the right switching gear are respectively movably sleeved on the left and right sides of the middle of the spline shaft 206. 205, the middle of the spline shaft 206 is movably connected with the pretreatment switching mechanism, the right end of the spline shaft 206 is movably connected with the inner wall of the power drive compartment 102, the front side of the left sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com