Rotary material falling type functional food intermediate drying device and drying process

A functional food and drying device technology, applied in the direction of non-progressive dryers, drying solid materials, drying chambers/containers, etc., can solve the problem of serious energy consumption, achieve high atomization degree, improve dryness, Good heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

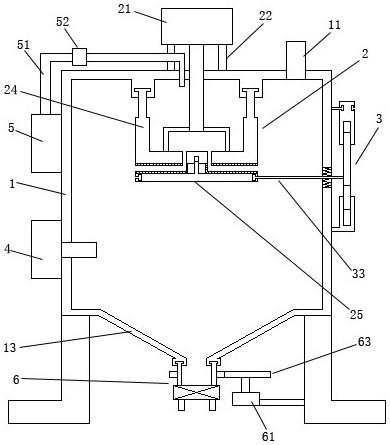

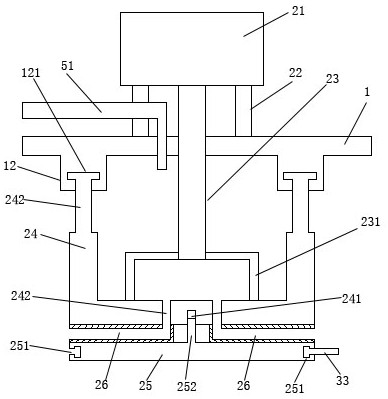

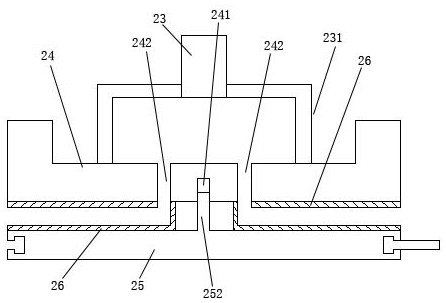

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 5 As shown, a rotary blanking type functional food intermediate drying device includes a body 1, a centrifugal mechanism 2, a floating adjustment mechanism 3, a liquid material box 5, a hot air flow generator 4, and a rotary blanking mechanism 6; the body A centrifugal mechanism 2 is installed in the middle of the upper end of 1; the centrifugal mechanism 2 includes a driving motor 21, a rotating shaft 23, a support ring body 22, a centrifugal cover 24, a floating bottom plate 25, and a diversion hose 26; the driving motor 21 is installed on the body 1 outside the upper end; the lower end of the driving motor 21 is installed with a supporting ring body 22; the lower end of the supporting ring body 22 is fixed on the outer surface of the upper end of the body 1; the upper end of the rotating shaft 23 is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com