Gas flow detection system

A detection system and gas flow technology, applied in the field of compressors, can solve problems such as large measurement error, high cost, and small fluctuations in detection pressure, and achieve the effects of simplifying structure, saving costs, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

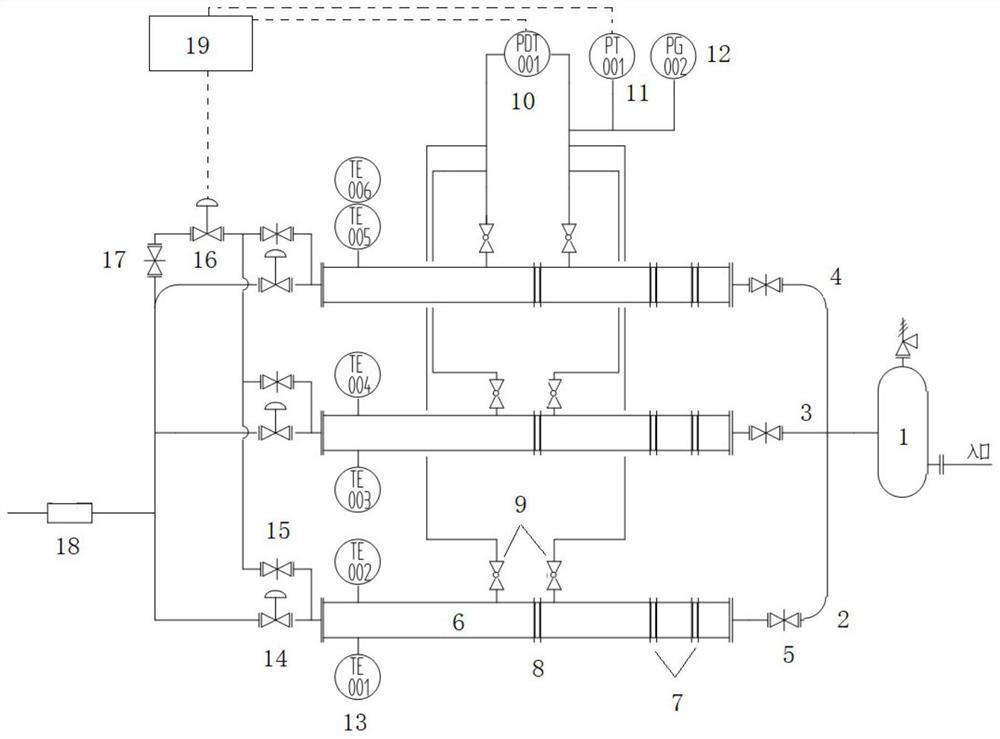

[0028] A flow detection system, its structure is as follows figure 1 As shown, the gas pipeline inlet of the detection system is connected to the compressor to be tested (the compressor to be tested is not shown in the figure), and then the gas storage tank 1 is installed, and the gas storage tank 1 is connected to the first detection unit 2 through three pipelines respectively. , the second detection unit 3 and the third detection unit 4, the same types of parts are arranged on the three monitoring units, but the specifications of the parts used are different, taking the first detection unit 2 as an example:

[0029] The entrance of the first detection unit 2 is provided with a gate valve 5, which is then connected to the flow cylinder 6. Two rectification orifice plates 7 are arranged at the front end of the flow cylinder 6. The orifice plate 8 is detected, and then flows out of the flow cylinder 6, and a temperature sensor 13 is arranged at the rear end of the flow cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com