Test device and method for simulating blasting excavation unloading

A test device, excavation and unloading technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem of inability to unload quickly, so as to improve unloading efficiency and accurate transmission mode , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

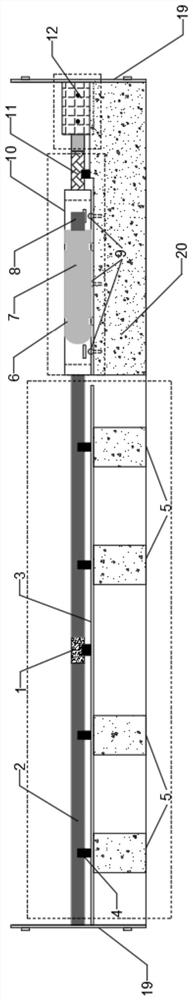

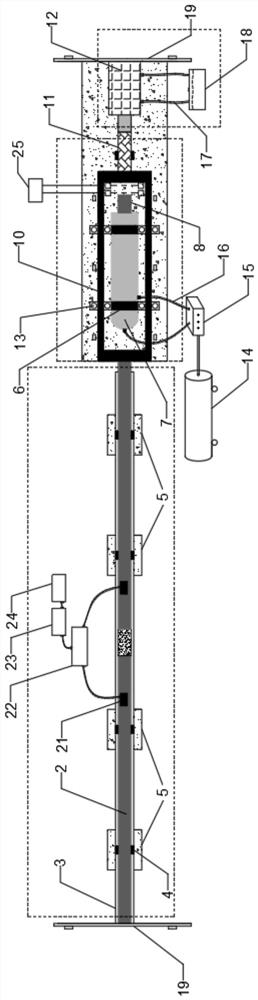

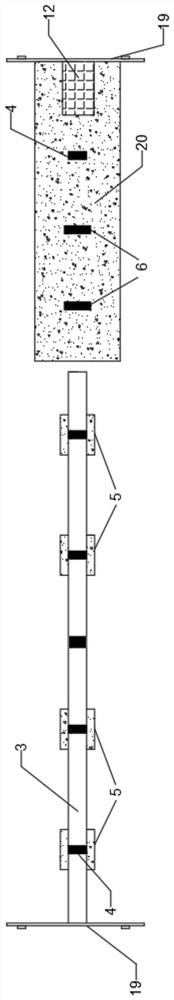

[0043] The present invention proposes a test device for simulating blasting excavation and unloading, such as figure 1 , figure 2 As shown, the device mainly includes a rock mass sample 1, a Hopkinson rod 2, a supporting component, a loading component, an unloading component, a fixing component and a monitoring component.

[0044] Two Hopkinson rods 2 are coaxially arranged, the end of the Hopkinson rod 2 at the front end is fixed, and it is set as a projection rod, and the end of the Hopkinson rod 2 at the rear end is provided with an unloading assembly, which is set as an injection projection rod , the two Hopkinson rods 2 are respectively provided with strain gauges 21 . A rock mass sample 1 is fixed between two Hopkinson rods 2 . The proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com