Pipeline hydrogen embrittlement temperature threshold prediction method based on hydrogen diffusion kinetics and application

A temperature threshold and prediction method technology, applied in measuring devices, scientific instruments, instruments, etc., can solve problems such as the inability to determine the relationship between the hydrogen atom aggregation rate and temperature, the inability to quantify the impact of hydrogen embrittlement on temperature, and the indetermination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

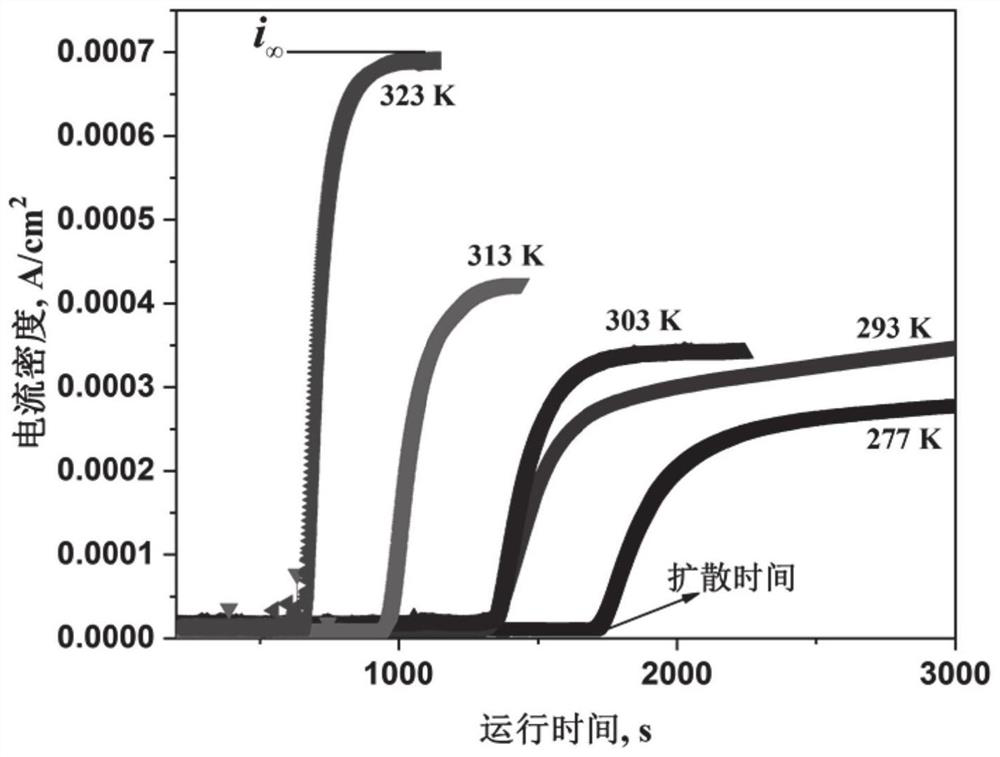

[0059] The material of the pipeline steel is X90, and the hydrogen permeation current density test is carried out, and the results are as follows figure 1 shown. Obtain matrix hydrogen concentration according to formula (1);

[0060] The saturation number N of hydrogen atoms is obtained according to formula (4),

[0061] The selection of R value is 160nm. v is Poisson's ratio value 0.31, a o is the lattice constant l z is the actual sample thickness. Ω H The value is 1.99×10 -30 m 3 .

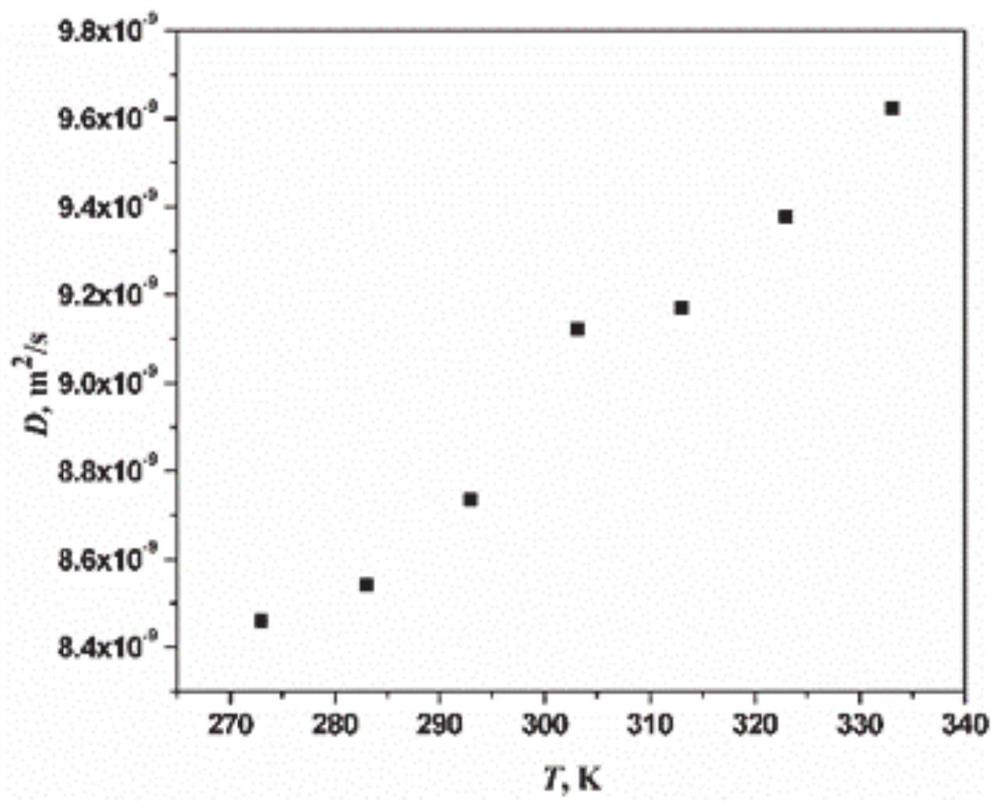

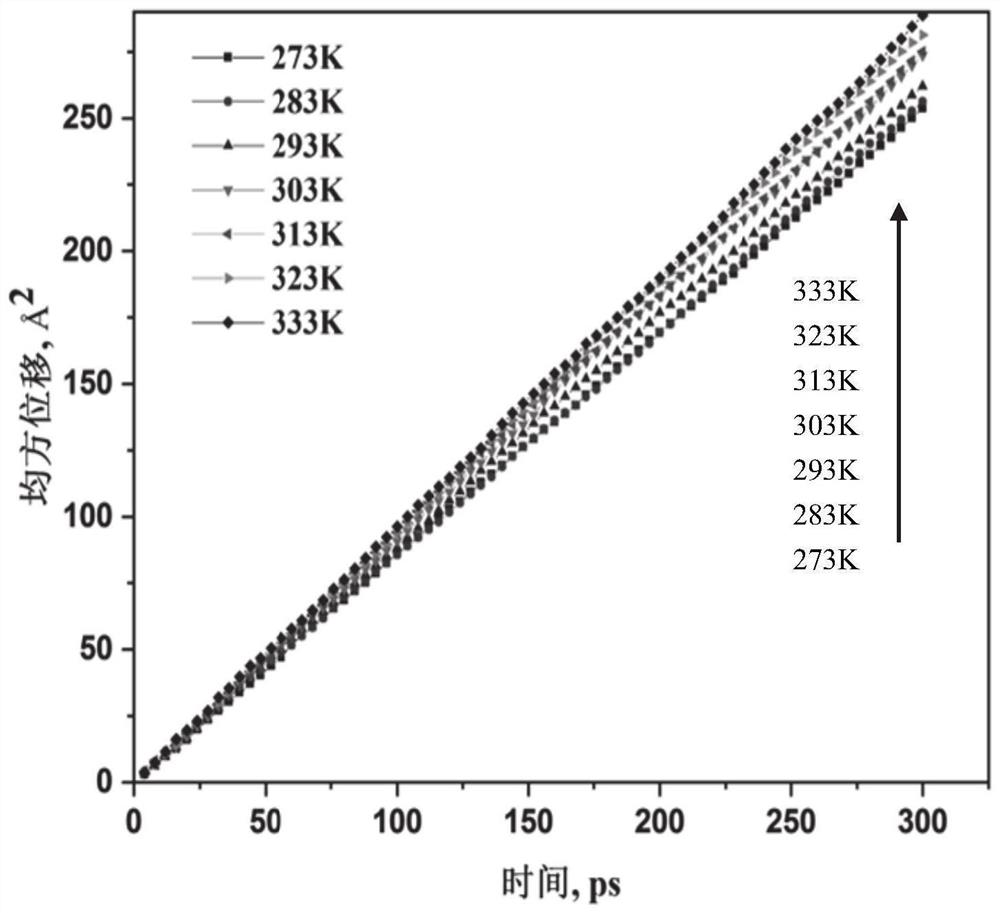

[0062] The relationship between temperature and diffusivity is as figure 2 shown. Through molecular dynamics simulation, the relationship between the diffusion rate of hydrogen atoms and temperature is obtained, that is, hydrogen atoms are randomly added to the body-centered cubic structure at different temperatures, and the relationship between the mean square displacement (MSD) of hydrogen atoms with time can be obtained by calculation. Substituted into formula (6),

[0063...

Embodiment 2

[0070] The hydrogen embrittlement temperature of Example 1 is verified, and the verification method is to use a device for verifying the hydrogen embrittlement temperature threshold to conduct a tensile test.

[0071] Such as Figure 5 As shown, the device for verifying the hydrogen embrittlement temperature threshold includes a corrosion box (model DC-2006), a constant temperature layer is set on the side wall of the corrosion box, and the inside of the constant temperature layer is connected to the circulating medium 2, and the corrosion box is connected to the gas outlet pipe 4 and the pH adjustment tube. 6. Thermometer 1.

[0072] Before the tensile test, the N with a purity of 99.5% was used 2 , the solution was deoxygenated for 1 h.

[0073] After deoxidation, the pipeline steel is put into the corrosion box, immersed in the NS4 solution 3, the two ends of the sample are provided with a silica gel coating 5, the sample is sealed on the corrosion box by silica gel, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com