Device and method for measuring heat conductivity coefficient of transformer insulating oil under low-temperature condition

A technology of transformer insulating oil and thermal conductivity, which is applied in the direction of material thermal development, etc., can solve the problems of crystallization of insulating oil and reduction of insulating effect of insulating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

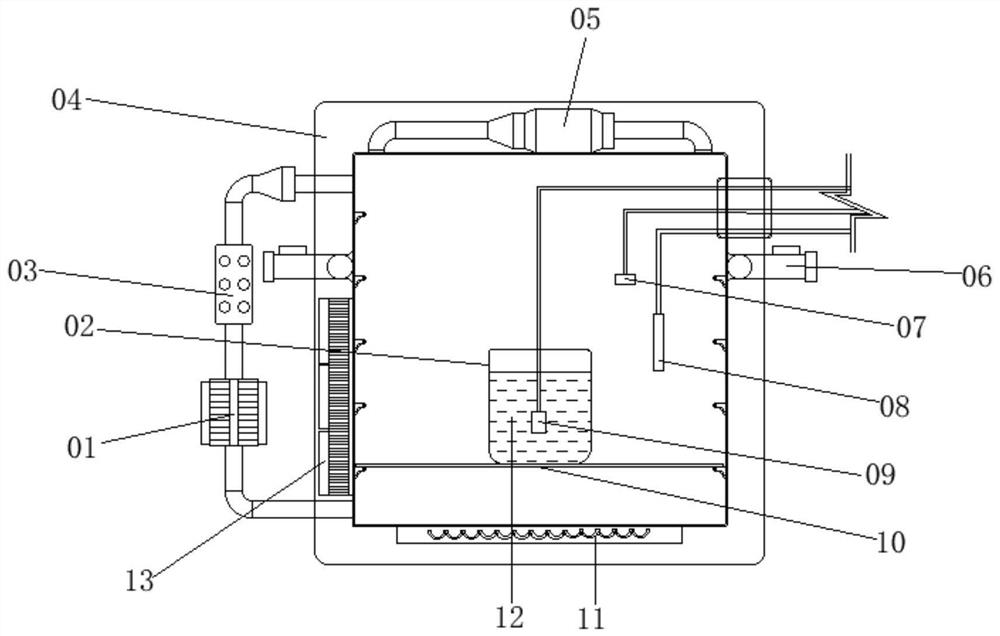

[0041] A device for measuring the thermal conductivity of transformer insulating oil under low temperature conditions, which simulates the actual working environment of insulating oil, and conducts a stable cooling process through the semiconductor electric cooling chip stack 13 of the thermal insulation layer 04 inside the device box, and finally controls the temperature at -40°C Left and right, the humidity is adjusted to 30% R.H. The following are the specific steps of the measurement using the device:

[0042] (1) Fill the experimental oil cup 02 with insulating oil 12 with a moisture content of 1%, set the initial temperature to 10°C, and the ambient humidity to 50% R.H. Turn on the pipeline fan 05 to stabilize the temperature and humidity in the container, then turn off the fan 05;

[0043] (2) The test water in the test chamber is deionized water. Before the test, ensure that the water level in the humidifier meets the normal working level;

[0044] (4) Adjust the ambien...

Embodiment 2

[0049] A device for measuring the thermal conductivity of transformer insulating oil under low temperature conditions. The actual working conditions of the simulated insulating oil are as follows. The initial temperature is 10°C. When a cold wave comes, the temperature drops 60°C within 1 hour, and the ambient humidity in the power equipment is 50%. R.H, the moisture content of the insulating oil is 1%, and the specific measurement method using the device includes the following steps:

[0050] (1) Fill the experimental oil cup 02 with insulating oil 12 with a moisture content of 1%, set the initial temperature to 10°C, and the ambient humidity to 50% R.H. Turn on the fan 05 to stabilize the temperature and humidity in the container, then turn off the fan 05 ;

[0051] (2) Set the cooling rate to 1°C / min, open the liquid nitrogen pipeline 06, set the liquid nitrogen shutdown predetermined temperature to -45°C, when the temperature drops to -45°C, close the liquid nitrogen chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com