Display panel and display device

A technology for display panels and substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as insufficient curing of the frame glue, adhesion and detachment of the frame glue and the substrate, etc., to improve the curing effect, increase the scattering and reflection paths, and ensure The effect of stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

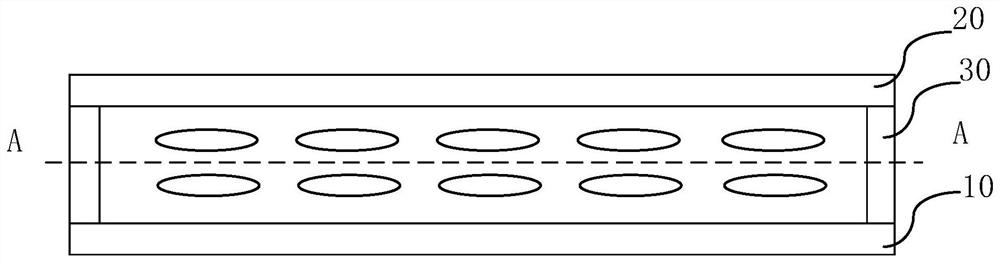

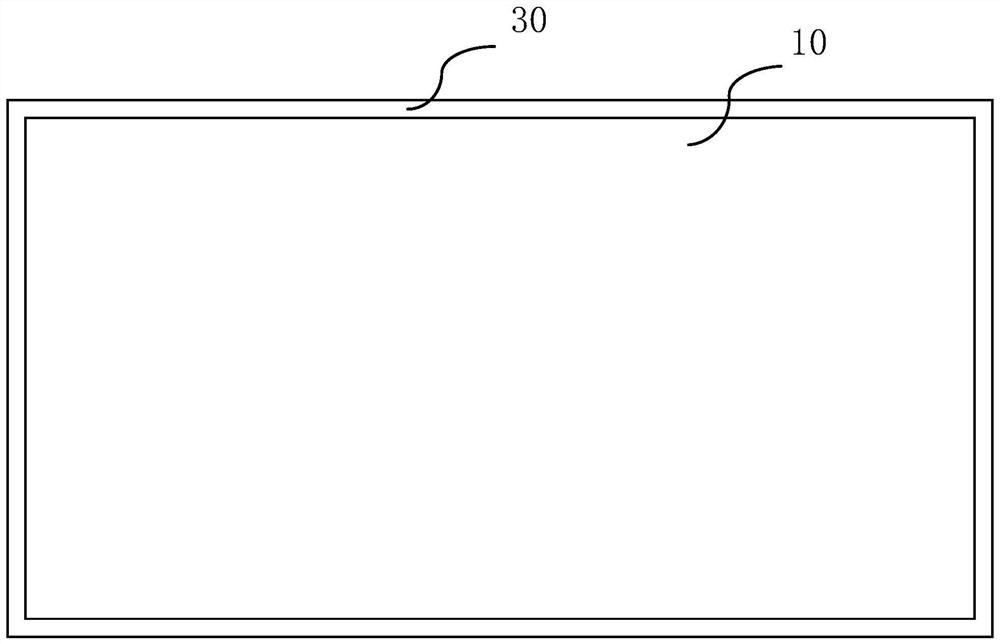

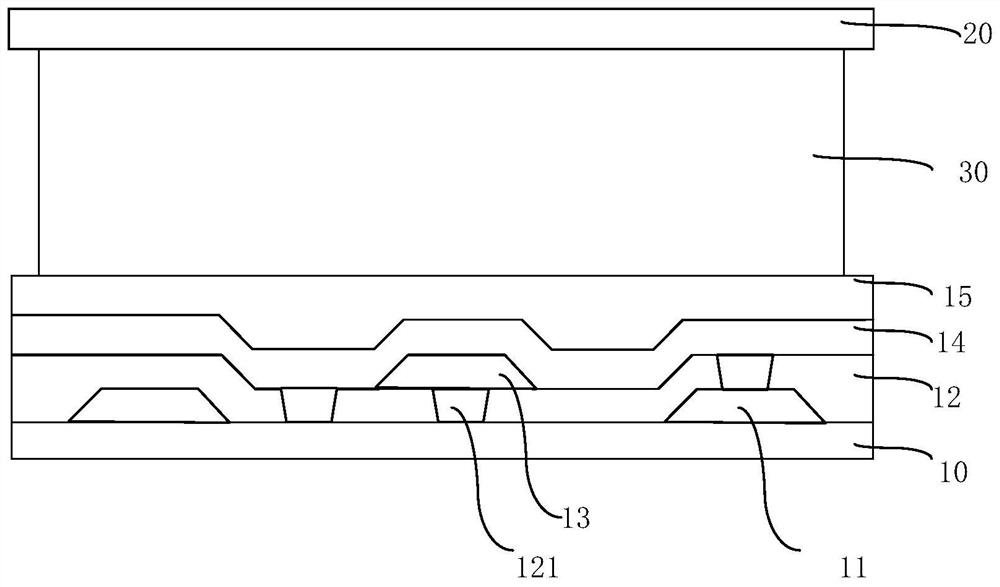

[0047] Please refer to image 3 , Embodiment 1 of the present application provides a display panel, the display panel includes: a first substrate 10, a second substrate 20, and a sealant 30 disposed between the first substrate 10 and the second substrate 20, the first substrate 10 and the second substrate 20 are fixedly connected by a sealant 30 . The display panel also includes a light-scattering layer 12 disposed between the first substrate 10 and the sealant 30 . When curing the sealant 30 in the display panel, an ultraviolet (UV) light emitting device may be disposed on the side of the first substrate 10 away from the sealant 30 . The ultraviolet light emitting device is used to generate UV light required for curing the sealant 30 . The UV light emitted by the ultraviolet light emitting device passes through the scattering layer 12 and then reaches the area of the sealant 30 . Due to the setting of the astigmatism layer 30, the scattering and reflection paths of the U...

Embodiment 2

[0060] Please refer to Figure 5 with Figure 4 , Embodiment 2 of the present application provides a display panel, the display panel includes a first substrate 10, a second substrate 20, and a sealant 30 disposed between the first substrate 10 and the second substrate 20, the first substrate 10 It is fixedly connected with the second substrate 20 through the sealant 30 . The display panel further includes a light-scattering layer 12 disposed between the first substrate 10 and the sealant 30 or between the second substrate 20 and the sealant 30 .

[0061] The structure of the display panel provided by the second embodiment of the present application is similar to that of the display panel provided by the first embodiment of the present application, and the similarities will not be repeated in this embodiment. The difference is that the light scattering structure 121 in the second embodiment of the present application is completely covered by the first metal wiring 111 and th...

Embodiment 3

[0063] Please refer to Image 6 with Figure 4 , Embodiment 3 of the present application provides a display panel, the display panel includes: a first substrate 10, a second substrate 20, and a sealant 30 disposed between the first substrate 10 and the second substrate 20, the first substrate 10 and the second substrate 20 are fixedly connected by a sealant 30 . The display panel also includes a light-scattering layer 12 disposed between the first substrate 10 and the sealant 30 .

[0064] The structure of the display panel provided by the third embodiment of the present application is similar to that of the display panel provided by the first embodiment of the present application, and the same parts will not be repeated in this embodiment. The difference is that the light-scattering structure 121 in the third embodiment of the present application is a groove. It should be noted that the groove only represents that the light-scattering structure 121 is not set through the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com