Bionic step-by-step compaction type ridging shaper

A technology of shaping machine and shaping board, applied in planting methods, agricultural machinery and implements, plows, etc., can solve problems such as inability to remove soil, difficult ridge body strength, and inconvenience in cleaning and processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

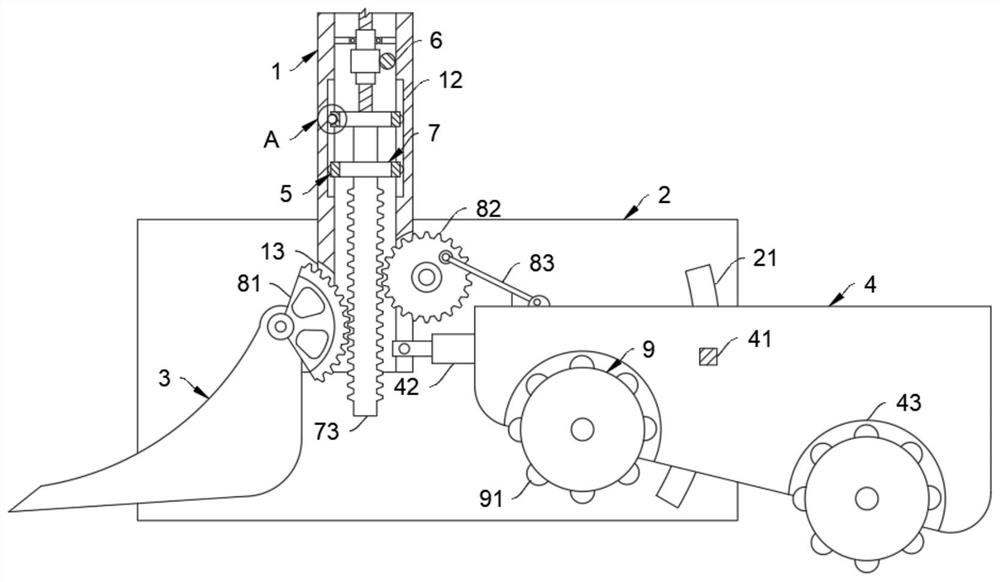

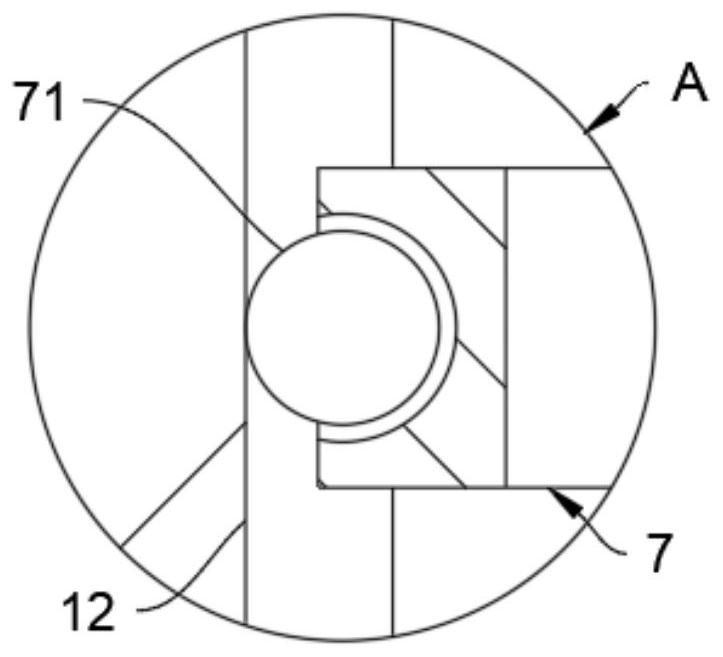

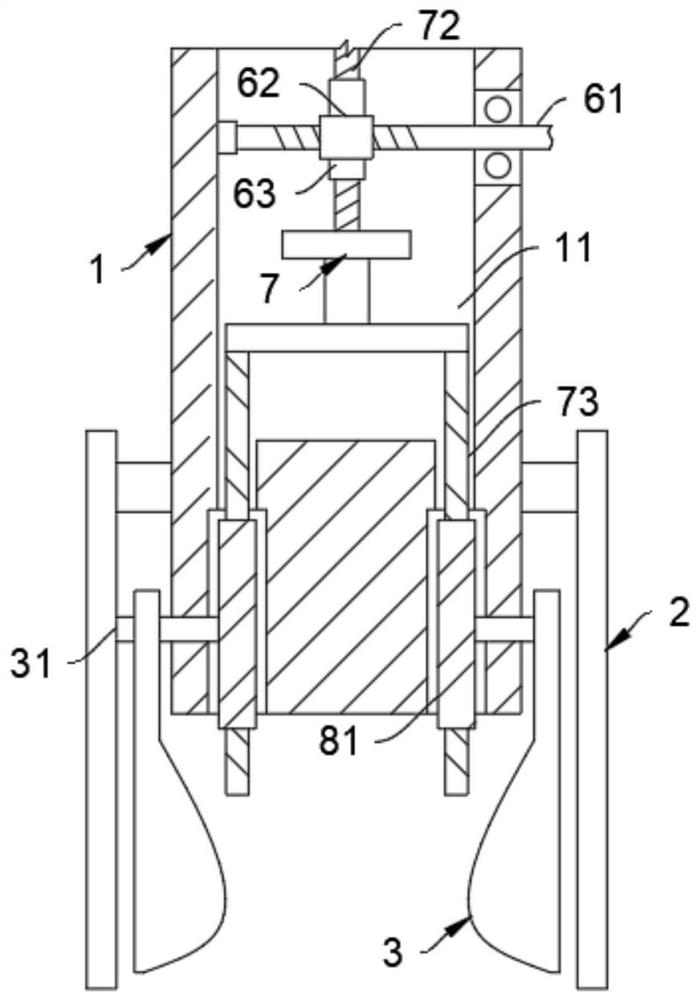

[0028] Such as Figure 1-4 As shown, a bionic step-by-step compaction ridge shaping machine includes a frame 1, and the frame 1 is symmetrically welded with a material retaining plate 2. It should be noted that the frame 1 is directly connected to driving equipment such as a tractor. To facilitate the assembly and disassembly of the device, the material retaining plate 2 adopts a rectangular structure, which is convenient for the shaping of the shaping plate 4 by blocking the plowed soil during the working process of the coulter 3 .

[0029] One end of the baffle plate 2 close to the frame 1 is rotatably connected with a coulter 3 , and the other end of the baffle plate 2 close to the frame 1 is slidably connected with a shaping plate 4 , and the frame 1 drives the coulter 3 and the shaping plate 4 through the transmission assembly 5 For ridging and shaping work, it should be noted that the coulter 3 adopts a curved surface structure, and the symmetrical mirror images are arra...

Embodiment 2

[0041] for Figure 5 The second shown embodiment is different from the first embodiment:

[0042] The blade surface of the coulter 3 is provided with multiple sets of scraping grooves 32, and the scraping grooves 32 are slidably connected with a scraper 34 through a spring 33. The middle part of the scraper 34 adopts a prismatic structure. It is worth mentioning that the length dimension of the scraper 34 is It is larger than the opening length of the scraper 32 to prevent soil from entering the scraper 32. By setting the prismatic scraper 34, not only the ridging effect of the coulter 3 is improved, but also the coulter 3 is retracted by the spring 33 The stretching makes the scraper 34 slide and scrape the curved surface of the coulter 3, reducing the adhesion of soil to the surface of the coulter 3, and improving the subsequent cleaning effect of the operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com