Online detection method and system for broken impurities of grain combine harvester

A combine harvester and detection system technology, applied to harvesters, cutters, computer parts, etc., can solve problems such as low efficiency, cumbersome work, and difficulty in online detection of broken rate and impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

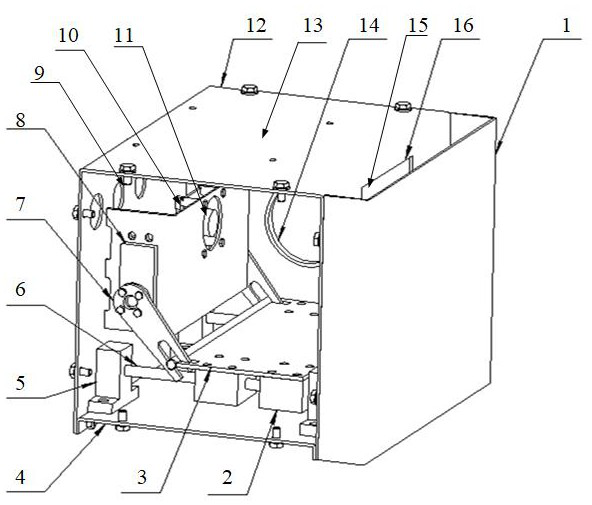

[0028] The embodiment of the present invention provides an on-line detection system for crushing impurities in a grain combine harvester, such as figure 1 As shown, the system includes:

[0029] Grain sampling bin 1, installed below the grain combine harvester grain outlet, for collecting the grain harvested by the grain combine harvester;

[0030] The side opening of the grain sampling bin 1 forms a grain sample photographing window 16;

[0031] The camera acquires grain sample images through the grain sample photographing window 16;

[0032] The camera device is communicatively connected to a data processing module 13, and the data processing module 13 is used to receive the image of the grain sample and calculate the breakage rate and impurity content rate. The data processing module 13 can choose an embedded data processing module, and the data processing module 13 realizes data communication with the outside through the CAN bus data connector 9 .

[0033] In order to a...

Embodiment 2

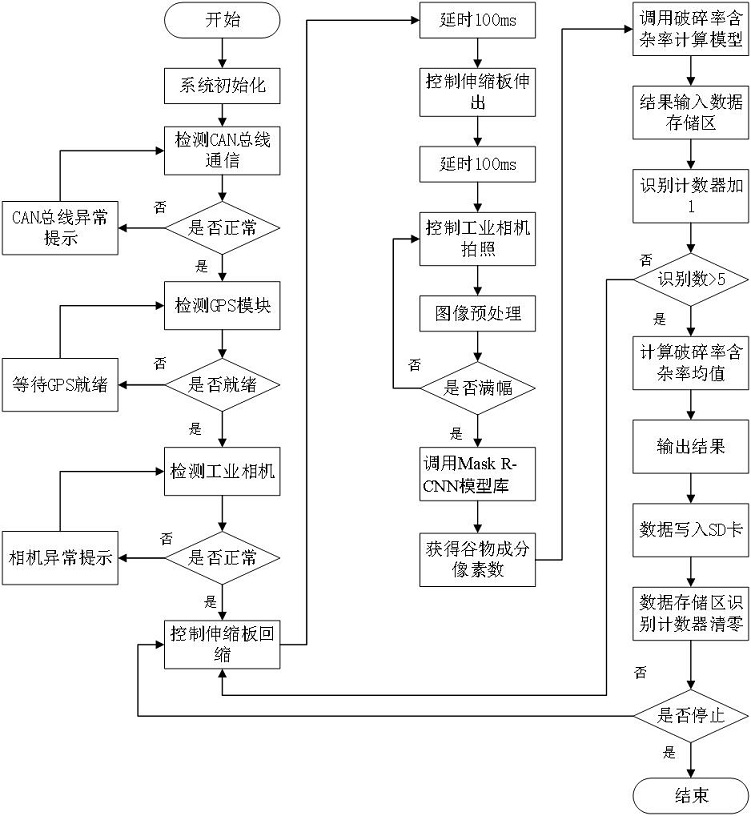

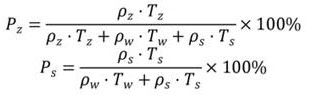

[0043] This embodiment provides a method for on-line detection of broken impurities in a grain combine harvester, such as figure 2 As shown, the method includes:

[0044] ① Receive detection instructions, including driver control instructions and camera control instructions.

[0045] ② Acquire grain sample images; according to the driver control command, control the driver to drive the telescopic plate 3 to retract, and the grain sampling bin 1 releases the grain sample, with a delay of 100ms; according to the driver control command, control the driver to drive the telescopic plate 3 to extend, and the grain sampling bin 1 Load grain samples with a delay of 100ms.

[0046]According to the control instructions of the camera device, take pictures of the grain samples and perform image preprocessing; judge whether the captured images meet the requirements (that is, the grains in the grain sampling bin 1 completely cover the shooting window, and the captured pictures are full of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com