Automatic punching machine for drill rod joint machining

A technology for automatic punching and drill pipe joints, applied in metal processing equipment, piercing tools, forming tools, etc., can solve the problems of time-consuming, labor-intensive, low efficiency, and relying on labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

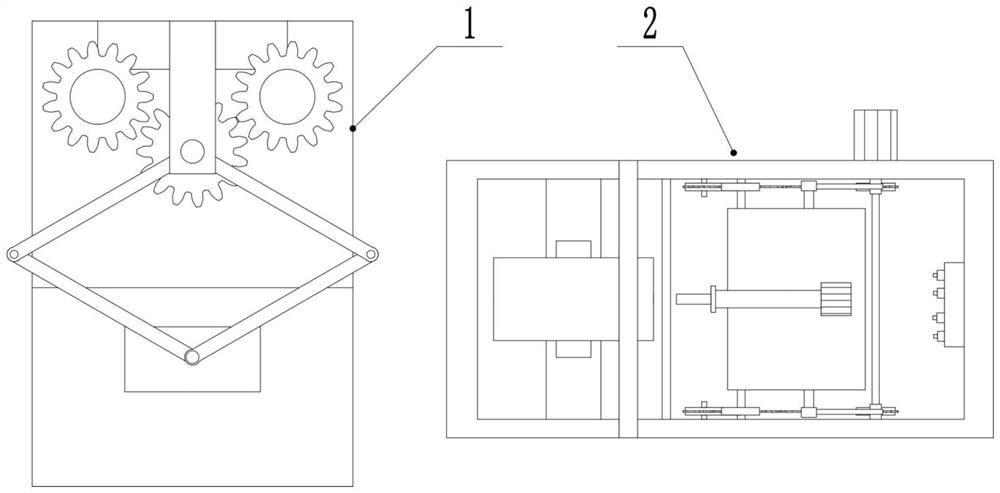

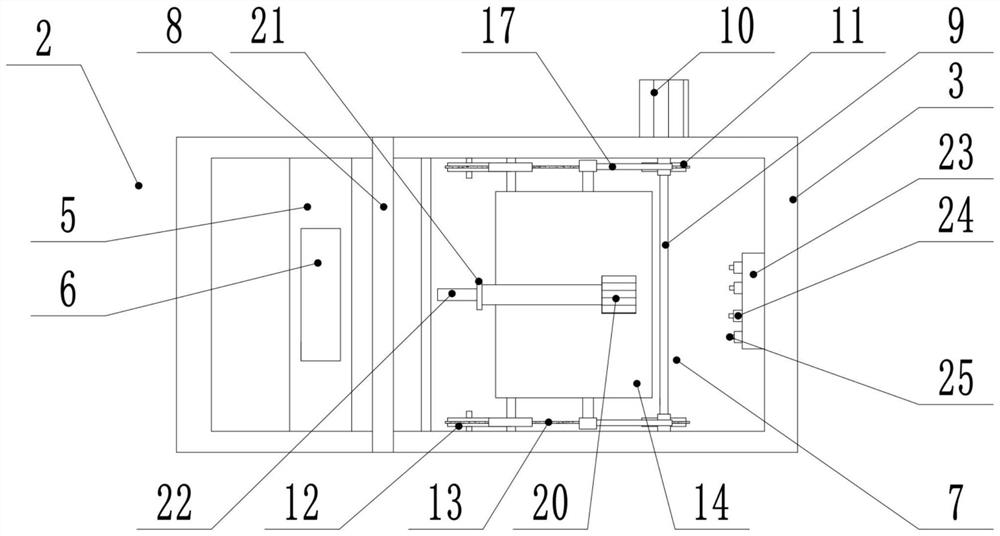

[0025] An automatic punching machine for processing drill pipe joints, comprising a punching device 1 and a blanking device 2 located on one side of the punching device 1;

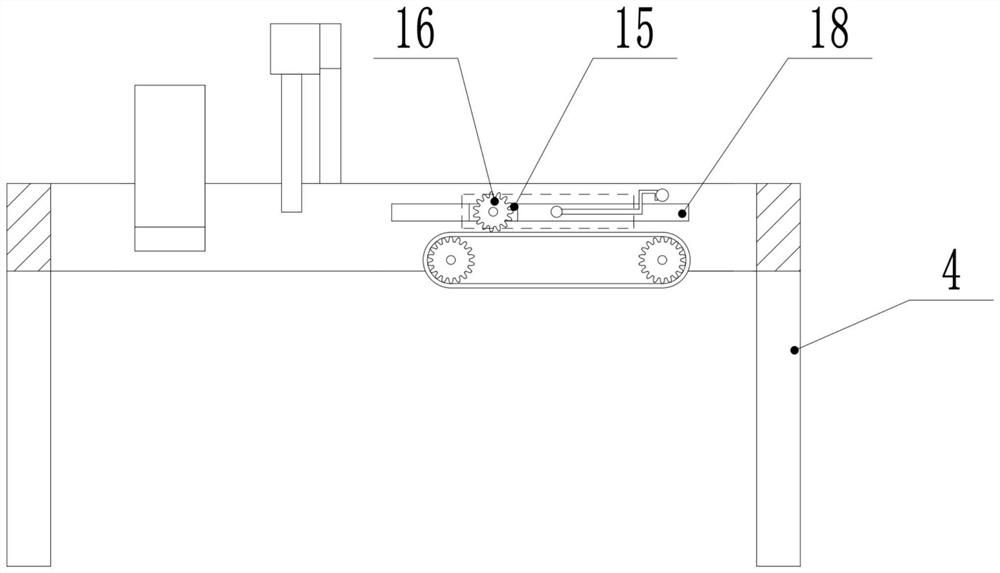

[0026] The punching device 1 comprises a work frame 3 of a frame structure, a support column 4 installed at the bottom of the work frame 3 and positioned at the four corners of the work frame 3, a support plate 5 installed on one side of the work frame 3, and a support plate 5 mounted on the support plate 5 And the support block 6 of V-shaped structure is installed on the work frame 3 and is located on the punching assembly 7 on the side of the work frame 3 away from the support plate 5, is installed on the work frame 3 and is located between the support plate 5 and the punching assembly 7 Between the first clamping assembly 8;

[0027] Punching assembly 7 comprises the ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap