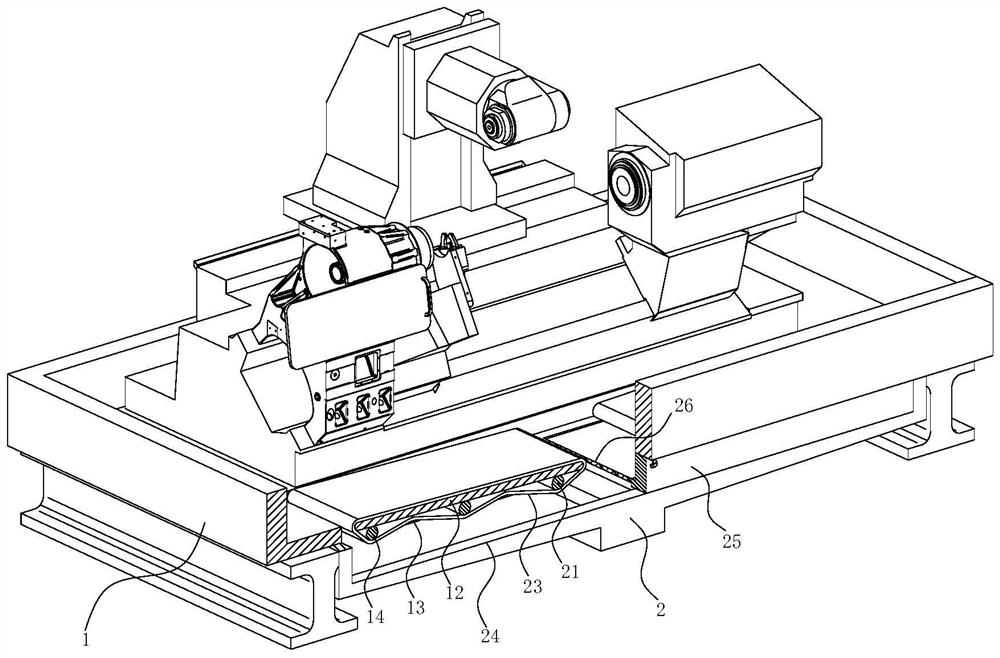

Chip removal and coolant recovery and filtration system for CNC machine tools

A technology of numerically controlled machine tools and filtering systems, applied in the field of numerically controlled machine tools, which can solve the problems of complex structure of multi-level mechanisms, weakened filtering and purification effects, cumbersome cleaning work, etc., and achieve the effects of enhanced filtering effects, rapid separation, and enhanced purification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

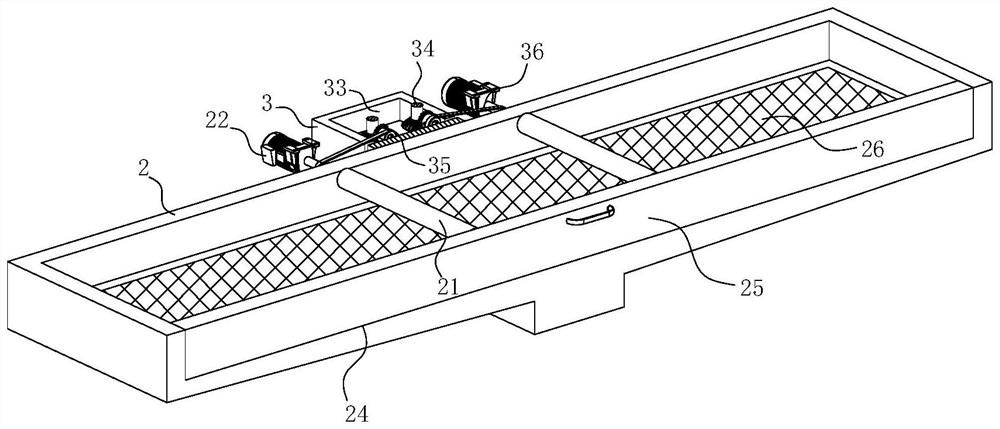

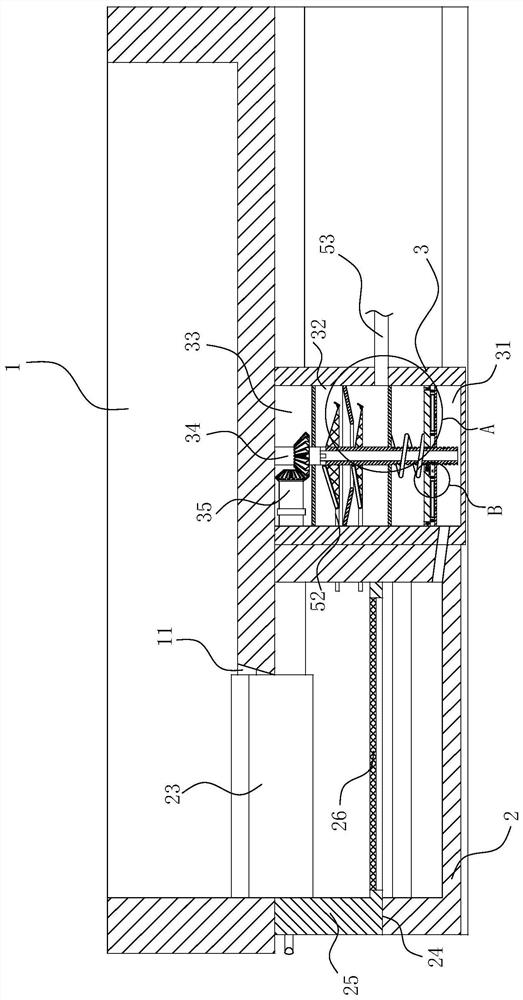

[0037] As an embodiment of the present invention, the receiving box 2 is located below the support plate 12 and is fixedly connected with evenly distributed limiting plates 13 and limiting columns 14; are all slidingly connected; the conveyor belt 23 is arranged in a wave shape below the support plate 12;

[0038] When working, the conveyor belt 23 receives and transports metal scraps and coolant. Under the impact of the coolant, the metal scraps easily enter the gaps of the conveyor belt 23. When the conveyor belt 23 runs to the support plate 12 under the drive of the rotating shaft 21 At the bottom, the conveyor belt 23 gradually bends and runs under the guidance of the limit plate 13 and the limit column 14. When the conveyor belt 23 bends, the surface gap expands, thereby facilitating the metal scraps in the gap to fall off under the action of gravity. Furthermore, it is avoided that metal scraps accumulate in the gaps of the conveyor belt 23 during long-term operation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com