A kind of organic solid waste thermal hydrolysis treatment system and its treatment process

A technology of organic solid waste and treatment system, applied in the direction of pyrolysis treatment of sludge, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of increasing process links, investment, operating costs, and limited heat recovery of high-temperature sludge and other problems, to achieve the effect of saving sludge conditioning energy and simplifying process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

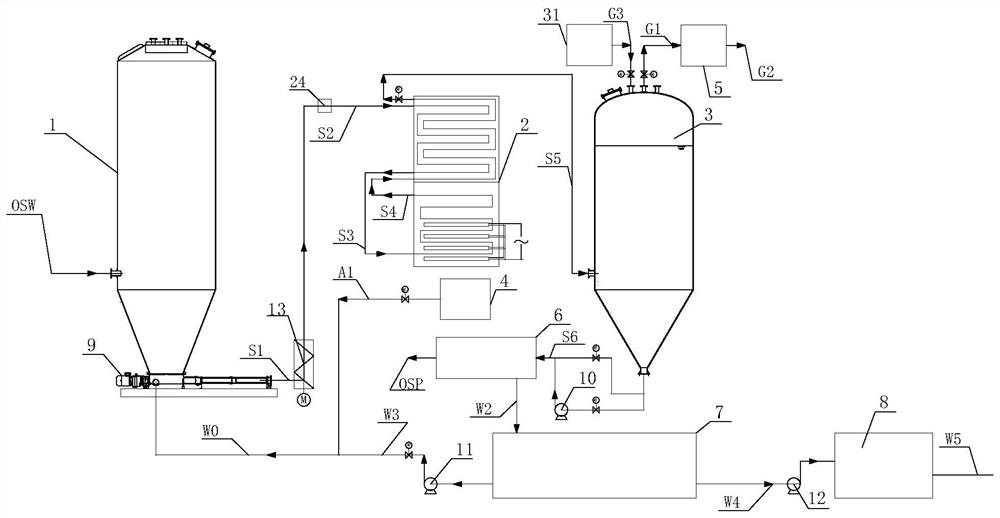

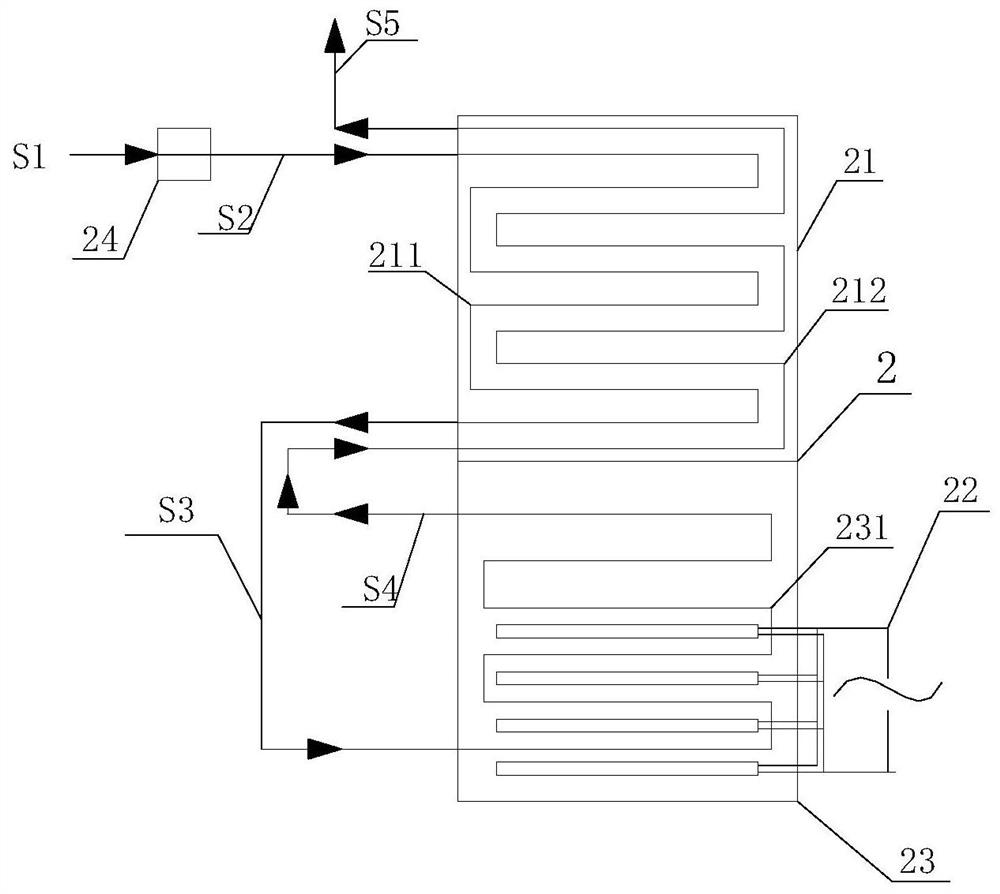

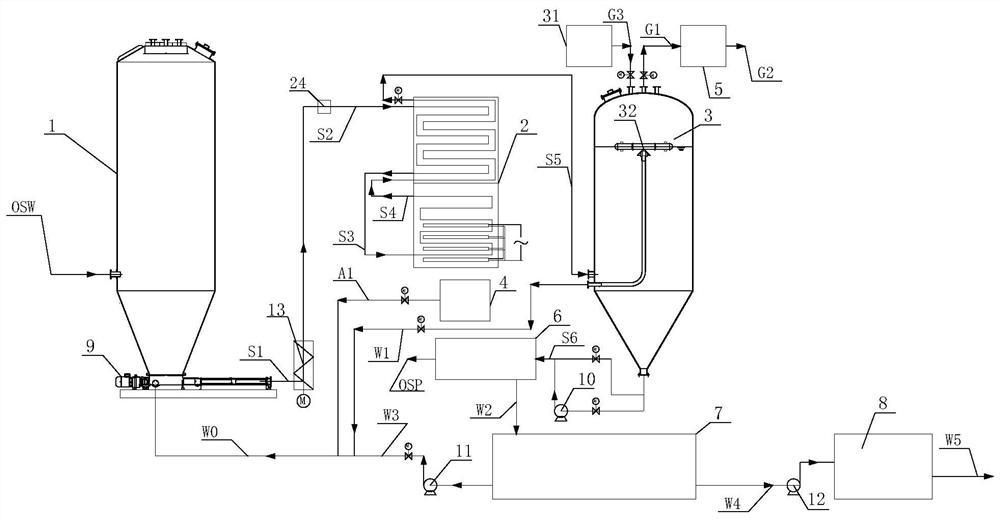

[0072] A kind of thermal hydrolysis treatment system of organic solid waste of the present invention such as figure 1 As shown, the main equipment includes sludge storage tank 1, pipeline self-heat exchange and reaction assembly assembly 2, reaction sludge pressure storage tank 3, lye tank 4, reaction gas processing unit 5, mechanical dehydration unit 6, sewage tank 7 and some pumping equipment, the pumping equipment includes sludge pump 9, dewatering water pump 10, raw mud water injection pump 11, external sewage pump 12, in addition, pulverizer 13 and sewage treatment unit 8 are selectively set according to needs; wherein, the pipeline Type self-heat exchange and reaction assembly assembly 2 includes a pipe-type sludge h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com