An anchoring system and method for strengthening ground fissures using magnetic cement mortar

A cement mortar and anchoring system technology, which is applied in the field of geotechnical engineering, can solve the problems of concentrated water seepage along the crack zone, uneven settlement of the basement, and infiltration of water bodies, so as to improve the magnetic field strength and traction force, and the opposite traction effect is obvious and increased. The effect of overall reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

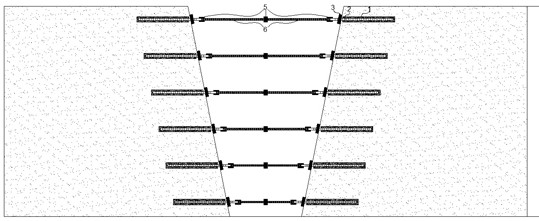

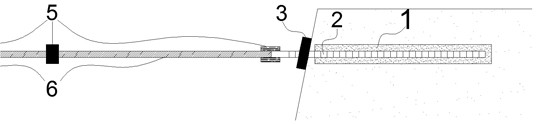

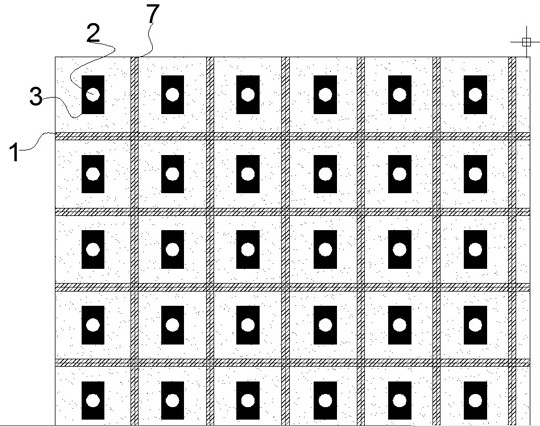

[0050] Such as Figure 4 Among them, an anchoring system that uses magnetic cement mortar to strengthen ground fissures includes an anchor rod 2 inserted into the crack or soil and a fixing structure 12 arranged at the front end of the anchor rod 2, and the maximum diameter of the fixing structure 12 is larger than that of the anchor rod. Rod 2 Diameter;

[0051] During the drilling process of the anchor 2, the fixed structure 12 limits the position so that holes are formed around the anchor 12. The diameter of the hole is larger than the diameter of the anchor. The magnetic cement mortar 1 is injected into the hole from the rear end of the anchor 2, and the fixed structure 12 prevents The magnetic cement mortar 1 flows out from the front end of the anchor rod 12, and the magnetic cement mortar 1 is formed by mixing cement, water, sand and magnetic powder in proportion.

[0052] Such as Figure 5 As shown, an anchoring system utilizing magnetic cement mortar to strengthen gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com