A lap joint method of different waterproof materials for side wall and roof

A waterproof material and waterproof coating technology, which is applied in building thermal insulation materials, buildings, building components, etc., can solve the problem that the overlapping parts of the side wall waterproof layer and the roof waterproof layer are not handled properly, the roof waterproof material cannot be fused with the roof, and the building can be accelerated. Corrosion speed and other issues, to achieve the effect of simple structure, low cost, and reduce leakage hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for overlapping the different waterproof materials of the basement side wall and the planting roof provided in this embodiment comprises the following steps:

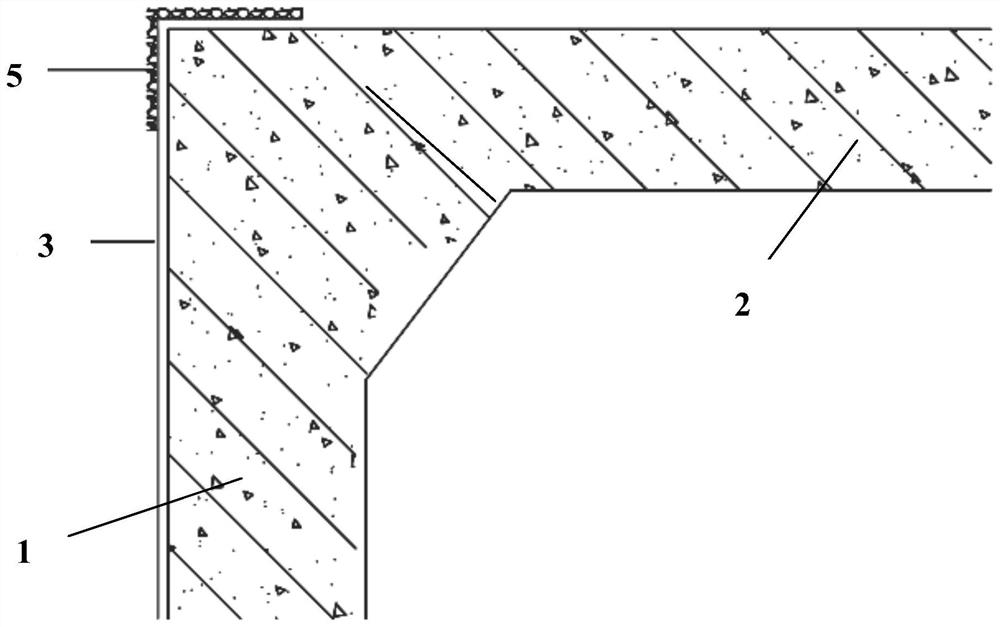

[0032] 1) see figure 1 As shown, the anti-sagging MPU polyurethane waterproof coating is applied to the side wall 1 multiple times to form a 2.0mm thick side wall waterproof coating film 3, and the coating film extends to the top plate 2 through the joint between the side wall 1 and the top plate 2 , the width of the coating film extending to the top plate 2 is 150mm;

[0033] 2) In step (1), after the last pass of anti-sagging MPU polyurethane waterproof coating is applied, when the last pass of the coating is not cured, the joints of side wall 1 and roof 2 are respectively along the length direction of side wall 1 and roof 2 Spray clean medium-fine sand on the side wall waterproof coating film 3 on both sides of the male corner to form a sand layer 5, and the range of sandblasting is within 150mm fr...

Embodiment 2

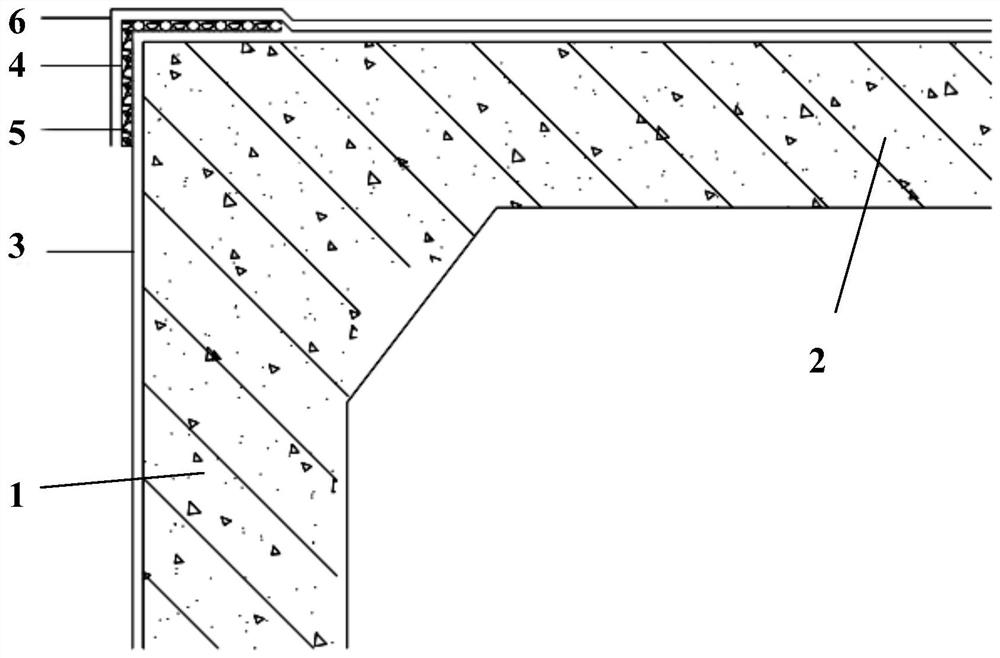

[0038] Repeat the test with the method of Example 1. After testing, the bonding strength between the roof waterproof coiled material 6 and the roof waterproof coating film 4 at the lap joint and the side wall waterproof coating film 3 reaches 2.2 MPa, and the side wall is waterproof. The coating film 3, the roof waterproof coating film 4 and the roof waterproof coiled material 6 can form a long-term effective sealing waterproof layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com