Second-order enhanced coupling beam type metal damping shock absorption system

A metal damping and shock absorption system technology, applied in the direction of earthquake resistance, building types, protective buildings/shelters, etc., can solve the problems of main structure damage, damage, high requirements, etc., to reduce earthquake disaster losses, uniform overall damage, The effect of easy material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] combine Figure 1 to Figure 12 , a second-order enhanced coupling beam metal damping system, including a plurality of coupling beam mild steel dampers 101, a plurality of coupling beam mild steel dampers 101 distributed in multiple floors, each floor is provided with at least one Coupling beam mild steel damper 101.

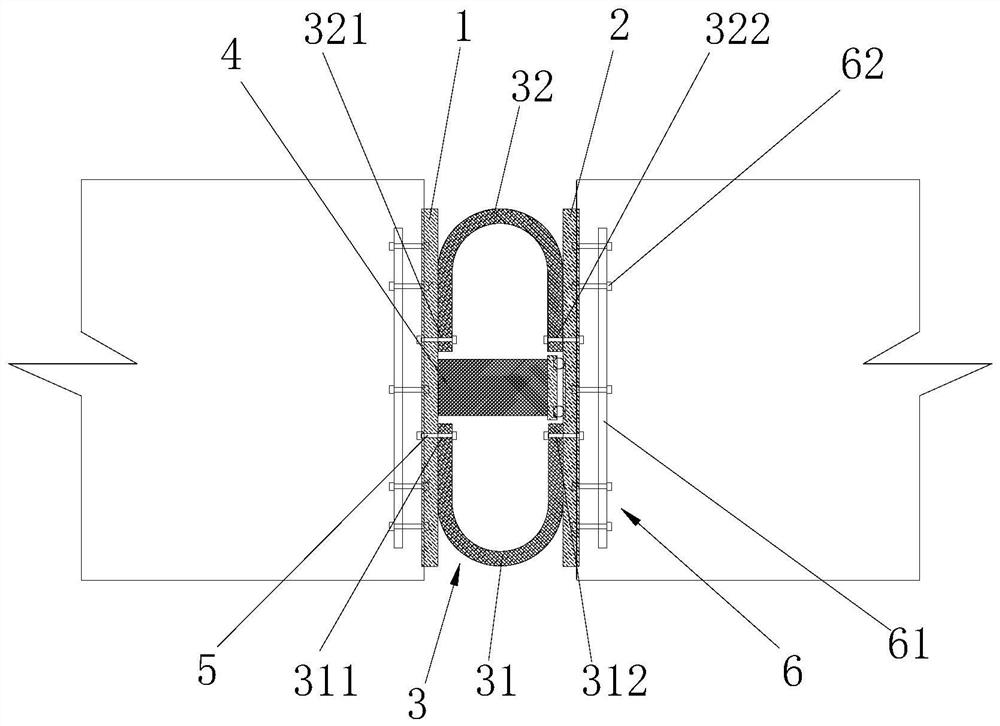

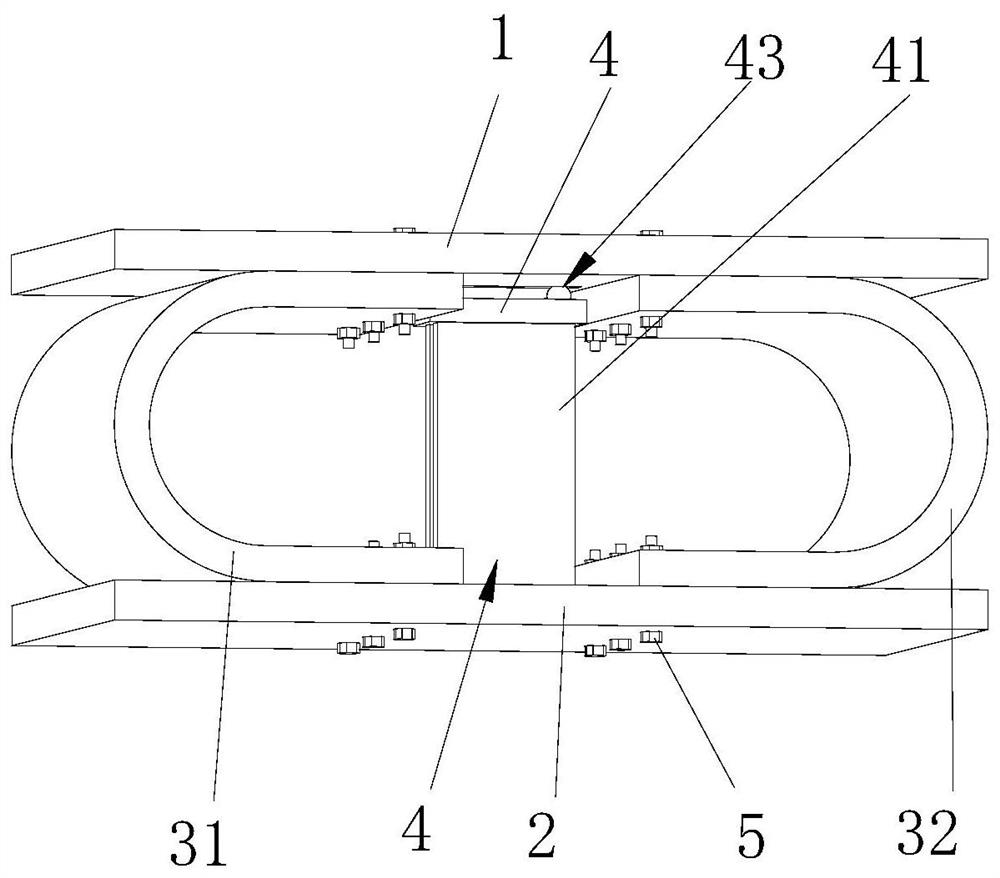

[0045] The connecting beam mild steel damper includes a first connecting plate 1 and a second connecting plate 2, a first energy dissipation mechanism 3 and a second energy dissipation mechanism 4 are arranged between the first connecting plate 1 and the second connecting plate 2, The first energy dissipation mechanism 3 includes a first U-shaped energy dissipation plate 31 and a second U-shaped energy dissipation plate 32 .

[0046] The second energy dissipation mechanism 4 includes a rectangular energy dissipation plate assembly 41 , one end of the rectangular energy dissipation plate assembly 41 is fixedly connected to the middle of the second connecting...

Embodiment 2

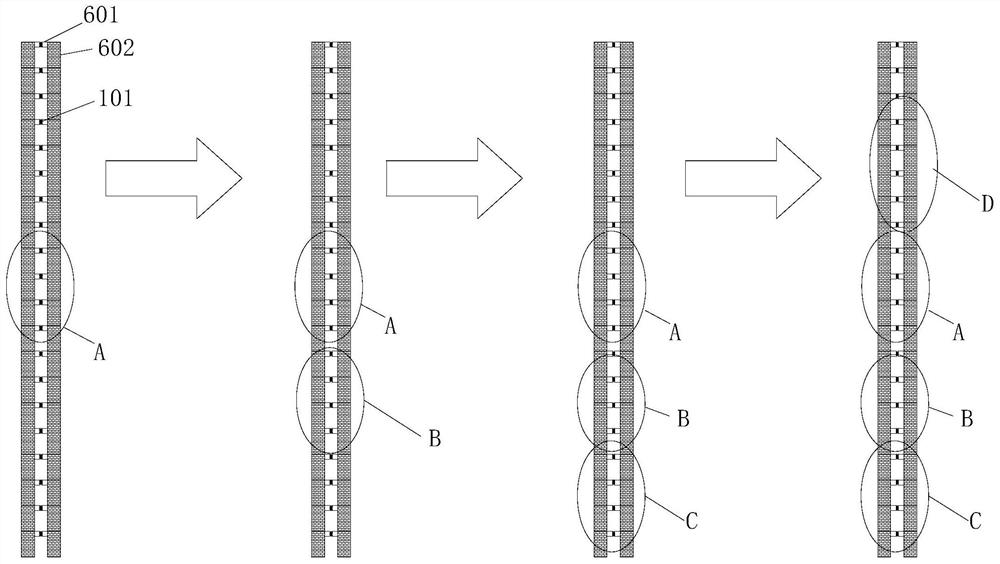

[0061] combine figure 1 , when the above-mentioned second-order reinforced metal damping system with beams is used, it can be used in ordinary multi-storey buildings, small high-rise buildings, high-rise buildings and super high-rise buildings. The second-order enhanced coupling beam metal damping shock absorption system in this embodiment is used for the shock absorption installation of a 20-storey building, and one or more coupling beam mild steel dampers can be arranged in each building. The bottom floor, the middle floor and the top floor of the building are all equipped with coupling beam mild steel dampers.

[0062] When a building encounters an earthquake, the connecting beams of the 20-story building will enter the reinforcement stage in turn.

[0063] Yield Enhancement Phase A. The floor where the yield enhancement stage A is located is the middle floor. After the coupling beam damper in the middle floor is stressed, the coupling beam mild steel damper in the middle...

Embodiment 3

[0069] combine figure 1 , the above-mentioned coupling beam mild steel damper uses high-strength bolts to connect each energy-dissipating component in turn, and realizes staged yield energy dissipation through mutual position constraints and deformation mode design. The second-order stiffness is greater than the first-order, and after the initial failure of a certain position, the seismic energy can be transferred to other undamaged floors to achieve uniform damage in sequence.

[0070] The specific implementation method is that when the energy dissipation sheet of the first stage is working, the energy dissipation sheet of the second stage is not working. When the displacement becomes large, the sliding support assembly of the limit makes the energy dissipation sheet of the second stage enter the working state and damp The overall rigidity of the device is enhanced. After the first stage energy consumption of the initial damaged part completes the stiffness improvement, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com