Machine vision-based cutter type discrimination and geometric parameter detection method and system

A technology of tool type and geometric parameters, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems affecting the production cycle of aircraft, scrapping workpieces, reducing processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

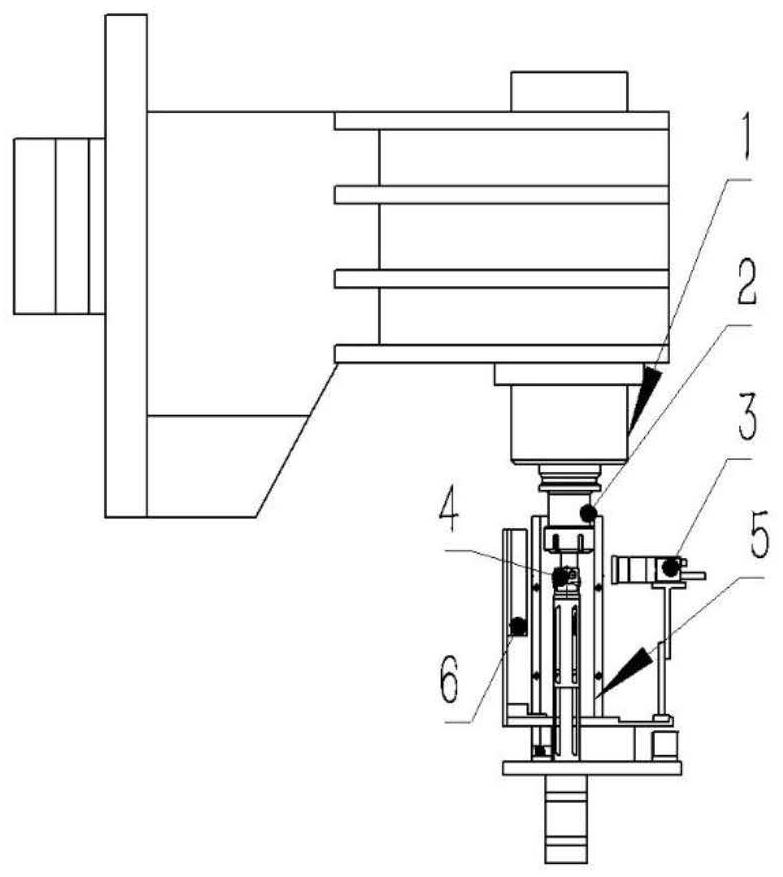

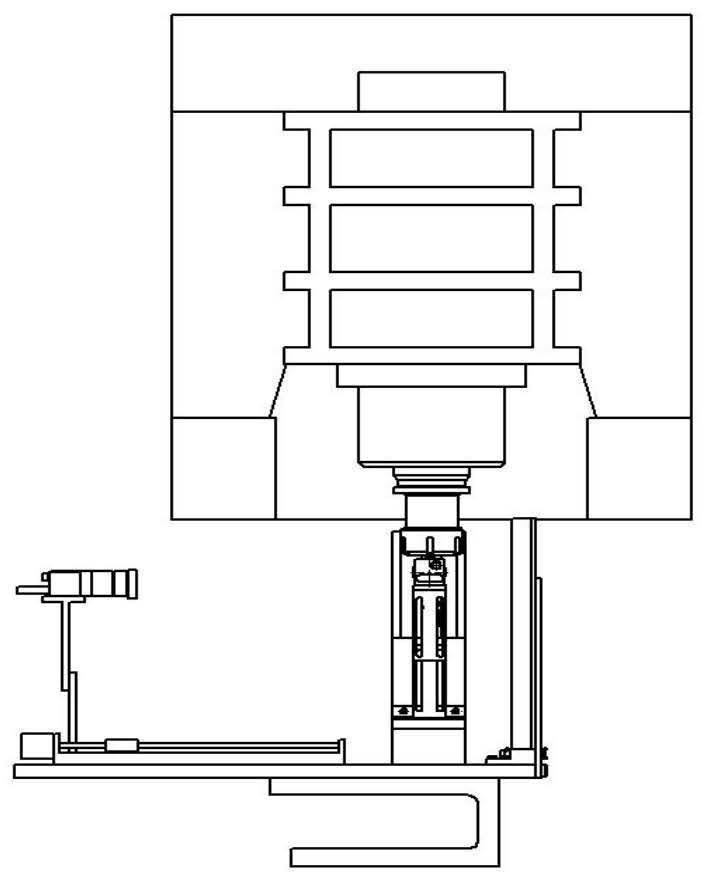

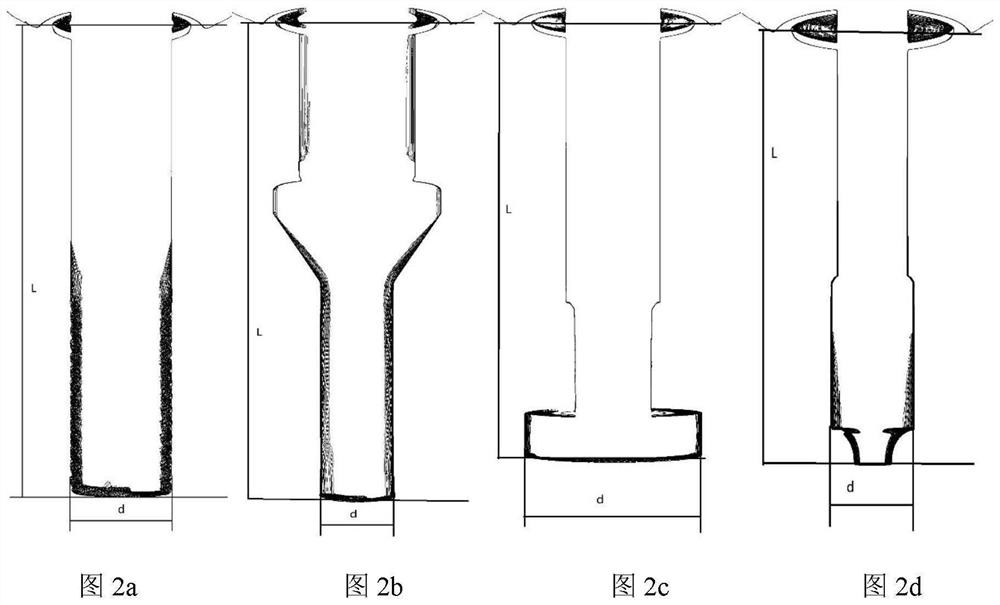

[0049] The present invention is a tool type discrimination and geometric parameter detection method based on machine vision, which is mainly aimed at the detection of tool type and tool geometric parameters in the tool change process of CNC machine tools, and compares the processing files to detect tool type errors and tool changes in the tool change process. When the geometric parameters of the tool do not match the actual processing requirements, an early warning is given to avoid large losses. It is mainly completed by camera, light source and computer; the tool is installed on the spindle, and the camera is fixed and installed next to the CNC machine tool table through a bracket. Every time the measurement is performed, the tool is moved to the designated position, and the image of the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com