Installation method of nuclear power station seawater liquid level measuring instrument

A technology of liquid level measurement and installation method, which is used in the direction of displaying liquid level indicators through pressure measurement, which can solve the problems that non-contact instruments cannot be reached, and cannot use differential pressure measurement, etc., to prevent siltation and facilitate disassembly and cleaning. The effect of repairing and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

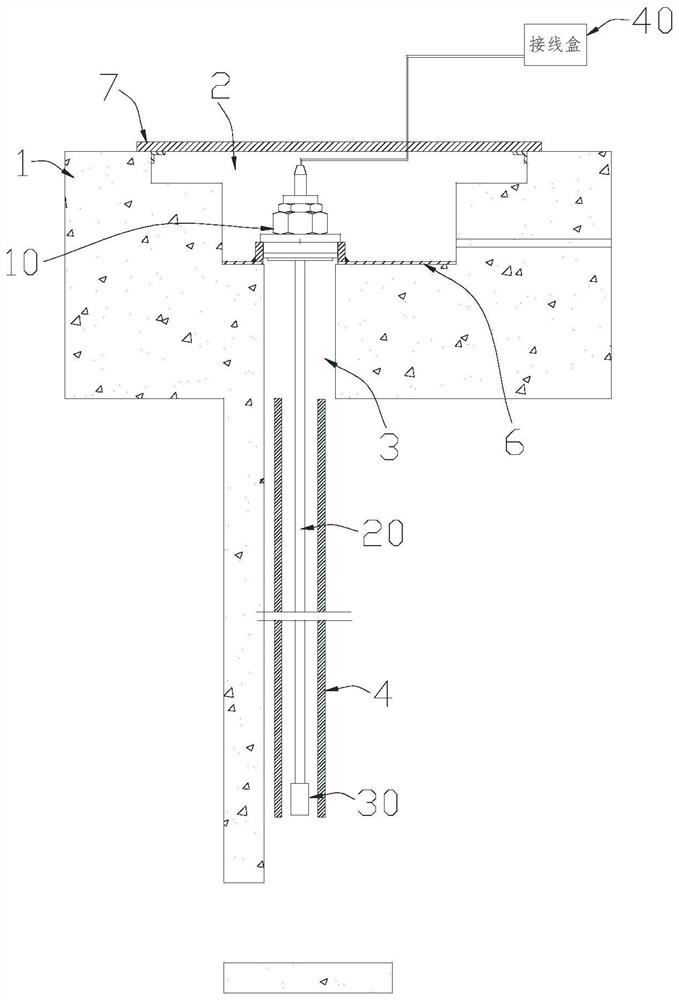

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0028] The installation method of the seawater level measuring instrument of the nuclear power plant of the present invention is used to install the seawater level measuring instrument before and after the forebay of the nuclear power plant united pumping room or the drum-shaped filter screen, so as to realize the measurement of the seawater level of the united pumping room forebay, or Measurement of the liquid level before and after the drum filter.

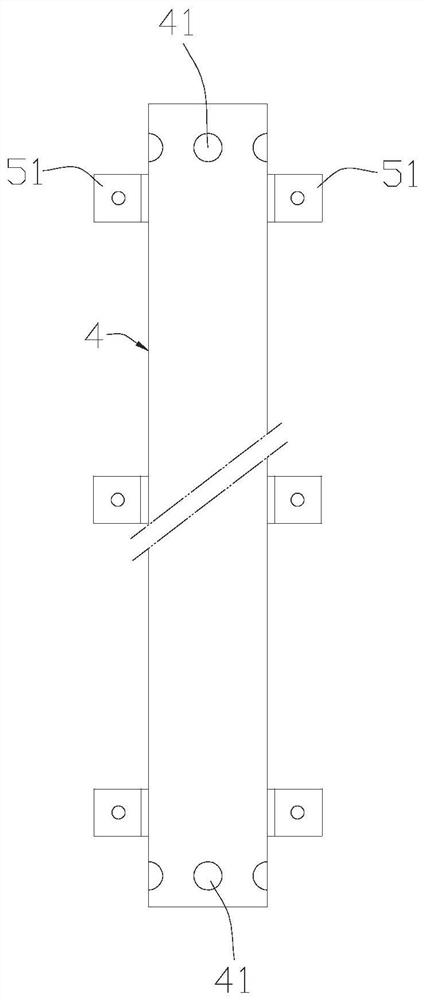

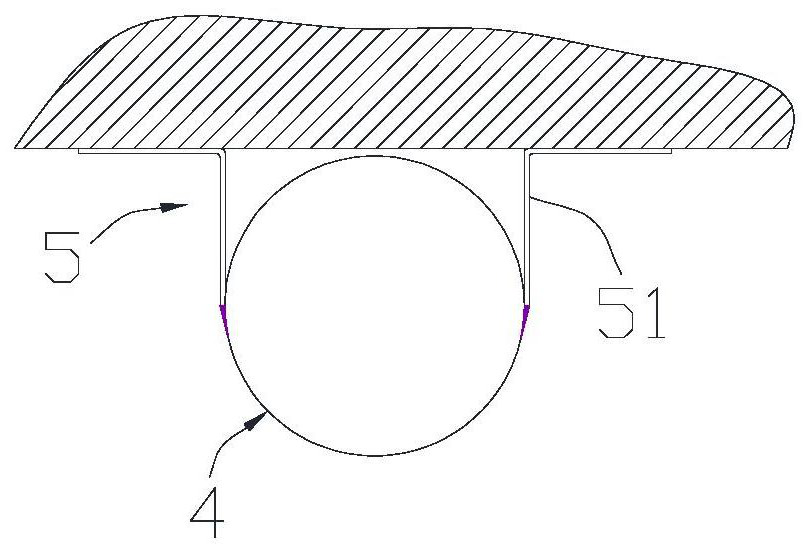

[0029] In the present invention, the seawater liquid level measuring instrument adopts a hydrostatic liquid level sensor, which includes a joint 10 , a probe 30 , a cable 20 connected between the joint 10 and the probe 30 , and a junction box 40 connected to the joint 10 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com