Equivalent expansion test system and method for studying two-phase expansion process

A technology of expansion process and testing method, applied in the direction of thermal expansion coefficient of materials, testing of machine/structural components, measuring devices, etc., can solve the problems of long cycle and high cost, and achieve high cost, simple structure, and controllable operating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] like Figure 4 As shown, the equivalent expansion test method of the present invention can adopt an open cycle.

[0046] The working fluid output module of the open system is directly connected to the atmosphere.

[0047] 1) Preparations before the start of the test: Check each test equipment to ensure that each test equipment is in good condition; keep the test system at the highest pressure operating condition to test the air tightness of the test system; calibrate the test instruments; Fill reservoir 1 with quality; close the valve on the test system.

[0048] 2) Testing phase:

[0049] Open stop valve 44-46, communicate with vacuum pump 9, vacuum tank 8, constant volume flash chamber 4 and working medium heating tank 3, use vacuum pump 9 to evacuate it; close all valves; open stop valve 42 again, the working medium Inject the working fluid into the heating tank 3, heat the water to the initial temperature; introduce the working fluid into the constant volume flas...

Embodiment 2

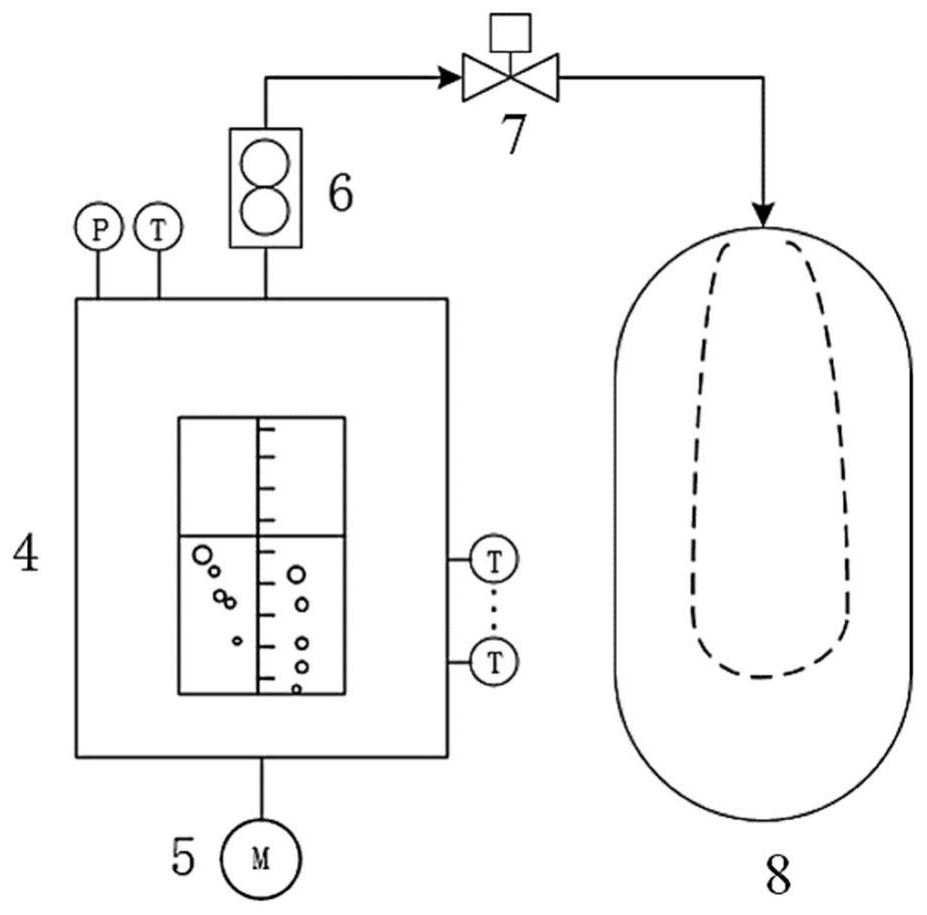

[0051] like Figure 5 As shown, the equivalent expansion test method of the present invention can adopt closed loop.

[0052] The working medium output module of the closed cycle recovers the working medium into the liquid storage tank 1, and this embodiment uses the constant volume flash chamber 4 with heating function, so the working medium heating tank 3 is removed.

[0053] 1) Preparations before the start of the test: Check each test equipment to ensure that each test equipment is in good condition; keep the test system at the highest pressure operating condition to test the air tightness of the test system; calibrate the test instruments; Fill reservoir 1 with quality; close the valve on the test system.

[0054] 2) Test stage: after starting the test, first heat the temperature of the constant volume flash chamber 4 to the initial temperature for preheating; open the valves 53 and 54, connect the vacuum pump 9, the vacuum tank 8 and the constant volume flash chamber 4,...

Embodiment 3

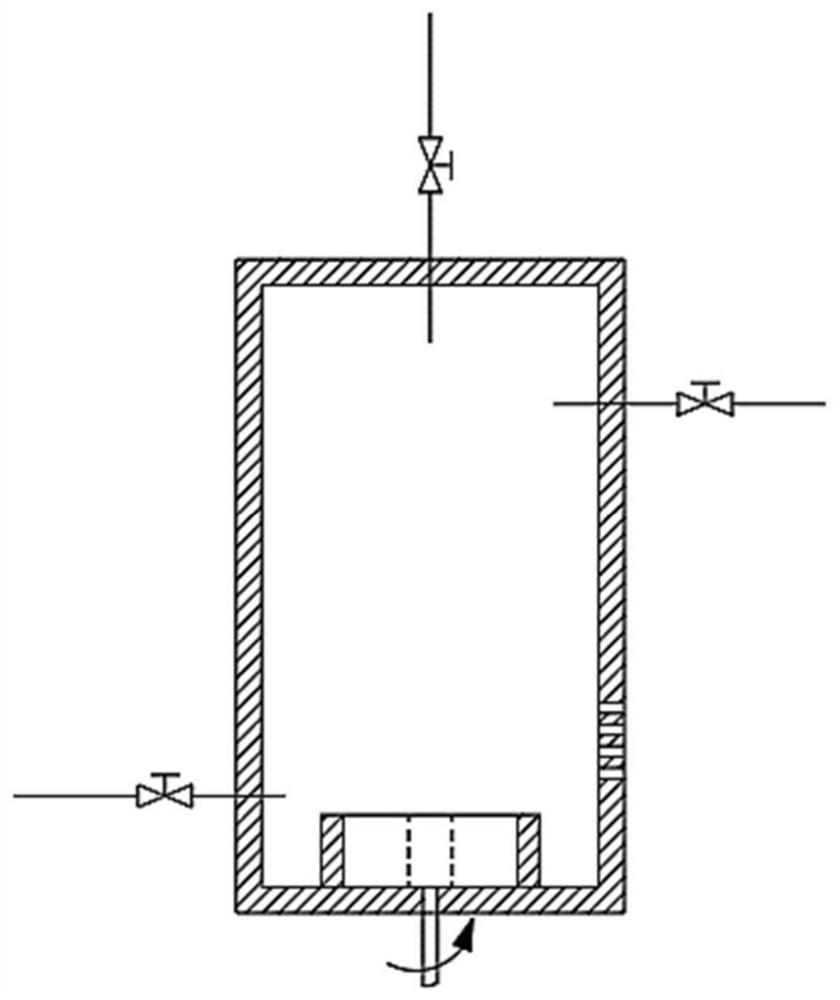

[0056] like Image 6 As shown, the equivalent expansion test method of the present invention can adopt a non-moving component cycle.

[0057] The circulation of non-moving parts does not use the working medium pump 2 and the compressor 10, and this embodiment uses the vacuum tank 8 with a condensing device, so the external condenser 11 is removed.

[0058] 1) Preparations before the start of the test:

[0059] Reasonably arrange the vacuum tank 8, the liquid storage tank 1 and the constant volume flash chamber 4 to ensure that the lowest point of the vacuum tank 8 is higher than the highest point of the liquid storage tank 1, and the lowest point of the liquid storage tank 1 is higher than the highest point of the constant volume flash chamber 4. point; check each test equipment to ensure that each test equipment is in good condition; keep the test system at the highest pressure operating condition to test the air tightness of the test system; calibrate the test instruments; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com